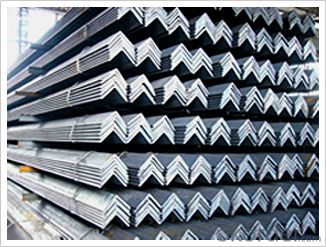

Hot rolled Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled Equal steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled Equal steel angle for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used for soundproofing applications?

- No, steel angles cannot be used for soundproofing applications.

- Q: What are the common thicknesses of steel angles?

- The common thicknesses of steel angles vary depending on the specific application and industry requirements. However, some commonly used thicknesses for steel angles include 1/8 inch, 3/16 inch, 1/4 inch, 3/8 inch, and 1/2 inch. These thicknesses are often used in construction, manufacturing, and structural applications. It is important to note that thicker steel angles provide increased strength and durability, while thinner angles are suitable for lighter applications. The choice of thickness ultimately depends on the specific load-bearing requirements and structural design considerations.

- Q: Can steel angles be used in pedestrian bridges?

- Yes, steel angles can be used in pedestrian bridges. Steel angles provide structural support, stability, and durability to the bridge, making them a commonly used material in bridge construction.

- Q: How do you calculate the effective length of a steel angle?

- To calculate the effective length of a steel angle, you need to consider two main factors: the actual length of the angle and the stability of the angle's supported members. Firstly, determine the actual length of the steel angle. This can be measured physically or obtained from the specifications provided by the manufacturer. Ensure that you have the accurate length value for the calculation. Next, assess the stability of the angle's supported members. The effective length of the angle is influenced by the conditions under which it is being used and supported. There are three primary support conditions to consider: pinned-pinned, fixed-fixed, and fixed-pinned. For a pinned-pinned support condition, the effective length is equal to the actual length of the angle. This condition assumes that both ends of the angle can freely rotate, resulting in the full length being effective in resisting the applied loads. In a fixed-fixed support condition, the effective length is typically considered as 0.7 times the actual length. This condition assumes that both ends of the angle are rigidly connected, reducing the effective length due to the increased stiffness of the overall system. For a fixed-pinned support condition, the effective length is usually 0.85 times the actual length. In this case, one end of the angle is fixed while the other end can freely rotate, resulting in a reduced effective length compared to the actual length. It is essential to correctly determine the support conditions of the steel angle to accurately calculate its effective length. Additionally, other factors like the angle's material properties, cross-section, and loading conditions should be considered in a comprehensive analysis of the angle's behavior.

- Q: Can steel angles be used for HVAC ductwork?

- No, steel angles are not typically used for HVAC ductwork. Ductwork is commonly made from galvanized steel sheets or flexible materials such as aluminum or fiberglass. Steel angles are more commonly used for structural support or framing purposes.

- Q: How much is the weight of 40 * 3 angle steel theory?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q: Are steel angles resistant to fire?

- Steel angles are generally considered to be fire resistant. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. However, it is important to note that while steel itself is resistant to fire, it can lose its strength when exposed to high temperatures for an extended period of time. In a fire situation, the temperature can rise rapidly, causing the steel to weaken and potentially compromise the structural integrity of a building or component. To enhance fire resistance, steel angles can be protected by applying fire-resistant coatings, such as intumescent paint or fireproofing materials. These coatings can provide additional insulation, delaying the steel's exposure to high temperatures and preventing its failure. Ultimately, the fire resistance of steel angles depends on various factors, including the duration and intensity of the fire, as well as the measures taken to enhance their fire performance. It is essential to consult with fire protection experts and adhere to building codes and regulations to ensure the appropriate level of fire resistance for steel angles in a specific application.

- Q: How do steel angles perform in corrosive gas or liquid environments?

- Steel angles perform well in corrosive gas or liquid environments, thanks to their high resistance to corrosion. The protective oxide layer that forms on the surface of steel angles helps prevent the steel from being directly exposed to the corrosive elements, ensuring its durability and longevity in such environments.

- Q: How do you prevent corrosion on steel angles?

- There are several preventive measures that can be taken to avoid corrosion on steel angles: 1. Properly cleaning the steel angles is crucial before applying any protective coating. This involves removing dirt, rust, and other contaminants through methods like abrasive blasting, power tool cleaning, or chemical cleaning. 2. Applying a protective coating on steel angles is highly effective in preventing corrosion. Different types of coatings, such as paint, epoxy, zinc-rich coatings, or galvanization, act as barriers between the steel and the environment, keeping moisture and corrosive elements away from the metal. 3. Cathodic protection is another method to protect steel angles from corrosion. It involves connecting sacrificial metals like zinc or aluminum to the steel angles, which corrode instead of the steel when exposed to corrosive elements. Impressed current systems can also be used to provide a protective current to the steel, inhibiting corrosion. 4. Controlling the environment in which steel angles are installed can help prevent corrosion. This includes reducing exposure to moisture, humidity, or corrosive chemicals. Proper ventilation, ensuring proper drainage, and using protective coatings specifically designed for harsh environments can achieve this. 5. Regular inspection and maintenance of steel angles are essential to detect any signs of corrosion early on. Damaged or corroded areas should be promptly repaired to prevent further deterioration. Regular cleaning and reapplication of protective coatings can also help maintain the integrity of the steel angles. By implementing a combination of these preventive measures, the risk of corrosion on steel angles can be significantly reduced, allowing for a longer lifespan and maintained structural integrity.

- Q: How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

Send your message to us

Hot rolled Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords