Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Steel Equal Angle with Good Quality 160*160mm

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m and 12m

3. Sizes:

| Size(mm) | Mass(kg/m) | Size(mm) | Mass(kg/m) |

| 160*160*10 | 24.729 | 160*160*14 | 33.987 |

| 160*160*12 | 29.391 | 160*160*16 | 38.518 |

Packaging & Delivery of Steel Equal Angle with Good Quality 160*160mm:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

-Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

-Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 1 to 2 months.

Q4: How many tons per bundle?

A4: Around 2-3tons

Q5: How many tons can be loaded into one 20ft container?

A5: Around 23—25tons(6m)

Q6: How many tons can be loaded into one 40ft container?

A6: Around 23—25tons(12m)

Q7: How to avoid the rust after deliver the goods to the loading port?

A7: We will keep the goods at the port covered with water-proof material

Production flow of Steel Equal Angle with Good Quality 160*160mm:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

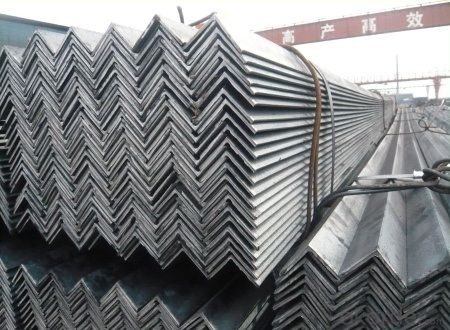

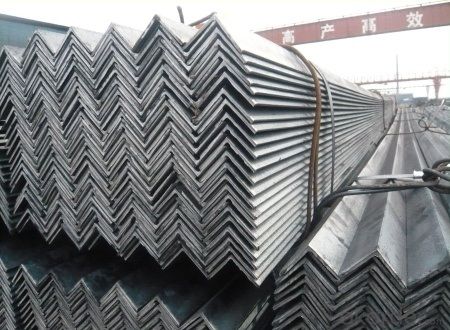

Images of Steel Equal Angle with Good Quality 160*160mm:

- Q: Can steel angles be used for manufacturing support brackets?

- Yes, steel angles can be used for manufacturing support brackets. Steel angles are commonly used in construction and manufacturing industries due to their strength and durability. They provide excellent support and structural integrity, making them ideal for creating support brackets. Steel angles are available in various sizes and thicknesses, allowing for customization based on the specific requirements of the bracket. Additionally, steel angles can be easily welded, drilled, and machined to fit the desired specifications, making them a versatile choice for manufacturing support brackets.

- Q: Can steel angles be used in sign support structures?

- Yes, steel angles can be used in sign support structures. Steel angles are commonly used in construction due to their high strength and durability. They provide excellent support and stability, making them suitable for a wide range of applications, including sign support structures. Steel angles can be easily welded or bolted together to create a sturdy framework for mounting signs. They also have a high load-bearing capacity, which is essential for ensuring the sign remains secure and stable, even in adverse weather conditions. Additionally, steel angles can be customized to suit specific design requirements, making them a versatile choice for sign support structures.

- Q: Can steel angles be used for mezzanines or catwalks?

- Mezzanines or catwalks can indeed utilize steel angles. The popularity of steel angles in these applications stems from their strength and versatility. They offer structural support and can be effortlessly bolted or welded together, forming a robust framework for mezzanines or catwalks. Furthermore, steel angles come in different sizes and thicknesses, enabling customization to fulfill specific design needs. In general, steel angles present a cost-efficient and dependable option for constructing mezzanines or catwalks in both commercial and industrial environments.

- Q: Can steel angles be used in automotive chassis construction?

- Yes, steel angles can be used in automotive chassis construction. Steel angles, also known as angle irons, are commonly used in the construction industry for their strength and versatility. In automotive chassis construction, steel angles can be used to provide structural support and reinforcement to the chassis frame. Steel angles are often used to create the frame structure of a vehicle's chassis, providing a stable and rigid framework. They can be used to form the main longitudinal and cross members, as well as other structural components. The use of steel angles in automotive chassis construction offers several advantages. Firstly, steel is a strong and durable material, making it suitable for withstanding the various stresses and loads experienced by the chassis. Steel angles can also be easily fabricated and welded, allowing for flexibility in design and customization. Moreover, steel angles are cost-effective compared to other materials such as aluminum or carbon fiber. This makes them a popular choice in automotive chassis construction, especially for mass-produced vehicles where cost efficiency is crucial. However, it is important to consider the specific requirements and regulations of the automotive industry when using steel angles in chassis construction. Chassis design must meet certain safety standards, including crashworthiness and structural integrity. Therefore, it is essential to ensure that the chosen steel angles and their dimensions are appropriate for the intended application and comply with relevant regulations. In conclusion, steel angles can indeed be used in automotive chassis construction. Their strength, versatility, cost-effectiveness, and ease of fabrication make them a suitable choice for creating the frame structure of a vehicle's chassis. However, it is important to consider safety regulations and ensure that the chosen steel angles meet the required standards.

- Q: What are the load-bearing capacities of steel angles?

- The load-bearing capacities of steel angles may differ due to various factors, such as the angle's size, thickness, and the type of steel used, as well as its specific application. Typically, steel angles are designed to offer structural support and can handle substantial loads. The load-bearing capacity of a steel angle is determined by its ability to withstand compression and tension forces, as well as its bending strength. These factors are influenced by the material properties of the steel, including its yield strength, tensile strength, and ductility. Steel angles find common usage in construction and engineering projects, where they are employed to support beams, frames, and structures. Engineers or designers usually specify the load-bearing capacity of a steel angle based on the project's specific requirements and the expected loads. Calculations and structural analysis, following engineering principles and standards, are typically carried out to determine the load-bearing capacity of a steel angle. These calculations take into account the angle's dimensions, support conditions, and the anticipated loads. To ensure that a steel angle's load-bearing capacity meets the necessary requirements for a given application, it is crucial to consult relevant engineering codes and standards provided by organizations such as the American Institute of Steel Construction (AISC) or British Standards Institution (BSI). In conclusion, the load-bearing capacities of steel angles can differ based on several factors. To accurately determine the load-bearing capacity of a specific steel angle for a given application, it is important to consult with a structural engineer or refer to appropriate engineering standards.

- Q: Are steel angles resistant to termites and pests?

- Steel angles do not possess resistance against termites and pests. Due to their metallic composition, termites do not find steel angles appealing as a source of nourishment. Nevertheless, termites can still inflict harm on adjacent materials, like wood or insulation, that might exist within the structure where steel angles are utilized. It is crucial to guarantee that the overall construction is resistant to termites and implement necessary precautions to avert infestations.

- Q: What is the typical corrosion rate of galvanized steel angles?

- The typical corrosion rate of galvanized steel angles can vary depending on several factors such as environmental conditions, exposure to corrosive agents, and the quality of the galvanized coating. However, in general, galvanized steel angles are known for their excellent corrosion resistance properties. The zinc coating on the steel acts as a protective barrier, preventing the underlying steel from coming into contact with corrosive elements such as moisture and oxygen. Under normal atmospheric conditions, galvanized steel angles can have a corrosion rate of approximately 1-5 microns per year. This corrosion rate can be further reduced in less aggressive environments or when additional protective coatings or maintenance practices are employed. Additionally, galvanized steel angles can exhibit even lower corrosion rates in dry or non-corrosive environments. It is important to note that in more severe or highly corrosive environments, the corrosion rate of galvanized steel angles can be accelerated. These environments may include high humidity, exposure to saltwater, acidic or alkaline conditions, or industrial atmospheres with high levels of pollutants. In such cases, it is advisable to consult with corrosion engineers or experts to determine the appropriate corrosion protection measures or alternative materials that may be more suitable for the specific application.

- Q: What are the safety considerations when working with steel angles?

- To work with steel angles effectively, it is essential to keep several safety considerations in mind. 1. Personal Protective Equipment (PPE): To safeguard oneself from potential hazards like flying debris, sharp edges, or falling heavy objects, always wear the appropriate PPE, including safety glasses, gloves, and steel-toed boots. 2. Lifting and handling: Due to their weight and bulkiness, proper lifting techniques and equipment should be employed to avoid strains or injuries. Use lifting aids such as cranes, hoists, or forklifts when necessary, and refrain from attempting to lift or carry steel angles alone if they exceed a safe weight limit. 3. Sharp edges and burrs: Steel angles often possess sharp edges and burrs that can cause cuts or abrasions. Exercise caution when handling them and consider deburring or filing down any sharp edges to minimize the risk of injuries. 4. Secure and stable work area: Ensure that the work area is clean, organized, and free from any tripping hazards. Store steel angles securely to prevent them from falling or rolling onto workers or equipment. 5. Welding and cutting: In case of welding or cutting steel angles, be mindful of the potential hazards associated with these processes. Use proper ventilation or respirators to protect against fumes and ensure that the work area is clear of flammable materials. Adhere to safety protocols and employ appropriate welding or cutting equipment to minimize the risk of fire, burns, or electric shocks. 6. Structural stability: When incorporating steel angles into a larger structure, it is critical to ensure that the design and construction adhere to industry standards and codes. This involves properly securing the angles, verifying load capacities, and conducting regular inspections to identify any signs of structural weaknesses or defects. 7. Training and supervision: Workers should receive adequate training on the safe handling, storage, and utilization of steel angles. Supervisors should actively monitor the work area and provide guidance to ensure adherence to safety protocols at all times. By adhering to these safety considerations, individuals can mitigate the risk of accidents and injuries when working with steel angles.

- Q: How do you determine the required number of steel angles for a project?

- Determining the required number of steel angles for a project involves considering several factors. Firstly, it is important to understand the design and specifications of the project. This includes the structural requirements, load-bearing capacities, and any specific angles or dimensions that need to be incorporated. Secondly, the dimensions of the steel angles need to be determined based on the intended use and structural requirements. This includes considering the length, width, and thickness of the angles that would be suitable for the project. Once the dimensions are established, the next step is to calculate the number of angles required. This can be done by carefully measuring and estimating the lengths of the steel angles needed in each area of the project. It is important to consider any potential waste or additional cuts that may be required during the installation process. In addition, it is recommended to consult with structural engineers or professionals experienced in steel fabrication to ensure accurate calculations and to confirm that the selected steel angles meet the necessary safety standards and building codes. Ultimately, determining the required number of steel angles for a project requires a combination of careful planning, accurate measurements, and professional expertise to ensure the project is structurally sound and meets all necessary requirements.

- Q: Can steel angles be used as a support for shelving?

- Yes, steel angles can be used as a support for shelving. Steel angles are sturdy and durable, making them suitable for bearing the weight of shelves and providing structural support.

Send your message to us

Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords