Steel Equal Angle with Good Quality 120*120*8.0-10.0mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Steel Equal Angle with Good Quality 120*120*8.0-10.0mm:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

| Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

| 120*120*8.0 | 14.57 | 120*120*10.0 | 18.055 |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Material details:

Grade | Element (%) | ||||

C | Mn | S | P | Si | |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Usage & Applications of Steel Equal Angle with Good Quality 120*120*8.0-10.0mm:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Steel Equal Angle with Good Quality 120*120*8.0-10.0mm:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Steel Equal Angle with Good Quality 120*120*8.0-10.0mm:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 1 to 2 months.

Q4: How many tons can be loaded into one 20ft container?

A4: Around 23—25tons

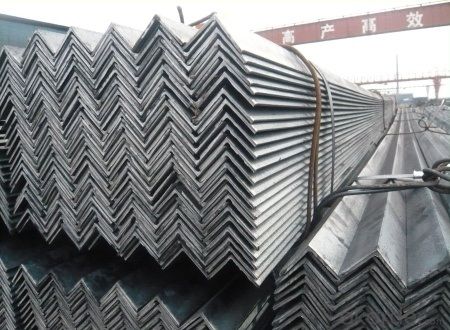

Images of Steel Equal Angle with Good Quality 120*120*8.0-10.0mm:

- Q: Can steel angles be used for structural applications?

- Yes, steel angles can be used for structural applications. Steel angles are commonly used in construction and engineering projects due to their strength, durability, and versatility. They are particularly useful in providing structural support and stability, as they can be easily welded, bolted, or otherwise connected to other steel components. Steel angles are often utilized in the construction of frames, supports, braces, and reinforcements. Additionally, their shape and design allow for efficient load-bearing capabilities, making them suitable for various structural applications such as bridges, buildings, towers, and industrial structures. Overall, steel angles are a reliable and cost-effective choice for structural applications.

- Q: How do you connect steel angles together?

- There are several ways to connect steel angles together depending on the specific application and load requirements. Here are a few common methods: 1. Welding: The most common and effective method is to weld the steel angles together. This creates a strong and permanent connection. It is important to ensure proper welding techniques are followed to maintain the integrity and strength of the joint. 2. Bolting: Another method is to use bolts and nuts to connect the steel angles. This allows for easy disassembly and reassembly if required. It is important to use the correct size and grade of bolts to ensure the connection can withstand the intended loads. 3. Riveting: Rivets can also be used to connect steel angles together. This method provides a strong and permanent connection, but it requires specialized tools and expertise to properly install the rivets. 4. Adhesive bonding: In some cases, adhesive bonding techniques can be used to connect steel angles together. This method is usually used in conjunction with other fastening methods, such as welding or bolting, to provide additional strength and stability. When choosing the method to connect steel angles, it is important to consider factors such as the load requirements, environmental conditions, and expected lifespan of the structure. Consulting with a structural engineer or a professional in the field is recommended to ensure the best connection method is chosen for your specific application.

- Q: Can steel angles be used for handrail supports?

- Yes, steel angles can be used for handrail supports. Steel angles are commonly used as a structural element in construction and can provide sufficient strength and stability to support handrails.

- Q: What are the common connections or fasteners used with steel angles?

- Steel angles can be connected or fastened using a variety of methods and materials. Bolts, screws, welds, and rivets are commonly used in this regard. When attaching steel angles to other structural elements or connecting multiple angles together, bolts and screws are often the go-to option. Welding, on the other hand, involves heating and fusing the angles together, resulting in a strong and durable bond. Rivets, which involve inserting a metal pin through holes in the angles and securing them with hammering or mechanical pressing, provide an alternative method of connection. The choice of connection or fastener depends on factors such as the specific application, load requirements, and desired aesthetics.

- Q: Are steel angles suitable for high-temperature environments?

- Steel angles can be suitable for high-temperature environments depending on the specific type of steel used. Certain grades of stainless steel, such as 304 and 316, are known for their excellent heat resistance properties. These stainless steel angles can withstand high temperatures without significant loss of strength or corrosion resistance. They also exhibit good oxidation resistance, which is crucial in high-temperature environments where oxidation can occur. However, it is important to note that not all steel angles are suitable for high-temperature applications. Carbon steels, for example, are not recommended for prolonged exposure to high temperatures as they can undergo significant structural changes, such as softening or even melting, which can compromise their integrity and strength. When selecting steel angles for high-temperature environments, it is essential to consider the specific temperature range, duration of exposure, and any additional factors such as corrosive gases or chemicals present. Consulting with a material engineer or a steel supplier with expertise in high-temperature applications can help ensure the selection of the appropriate steel angle with the necessary heat resistance properties for the specific environment.

- Q: Are there any limitations or restrictions on the use of steel angles in certain applications?

- Yes, there are limitations and restrictions on the use of steel angles in certain applications. One limitation is the maximum load-bearing capacity of the steel angles. Depending on the size, thickness, and quality of the steel angles, they may have a limited ability to support heavy loads. Therefore, in applications where high strength and load-bearing capacity are required, alternative structural members such as steel beams or columns may be more suitable. Another restriction is the suitability of steel angles for specific shapes or configurations. Steel angles are typically L-shaped, and while they are versatile and commonly used in various applications, they may not be ideal for certain complex or curved designs. In such cases, custom-shaped structural members or other materials may be more appropriate. Additionally, the corrosion resistance of steel angles is a limitation in certain environments. Steel is susceptible to rust and corrosion, particularly in marine or highly humid conditions. In applications where exposure to moisture or corrosive substances is inevitable, additional protective measures such as coatings or stainless steel angles may be required. Lastly, the fabrication and installation of steel angles may also impose limitations. Steel angles often require welding, cutting, or drilling during fabrication, which can be challenging in certain applications where precision and specialized equipment are necessary. Moreover, the size and weight of steel angles may pose limitations during transportation and installation, especially in confined spaces or areas with limited access. Therefore, it is crucial to consider these limitations and restrictions when selecting steel angles for specific applications, ensuring that they meet the required strength, shape, corrosion resistance, and installation requirements.

- Q: How do you calculate the buckling capacity of a steel angle?

- To calculate the buckling capacity of a steel angle, you need to consider several factors. Firstly, determine the effective length of the angle. This is the distance between points of rotation or points of restraint. Next, calculate the slenderness ratio, which is the effective length divided by the radius of gyration. The radius of gyration is a measure of how the steel angle's cross-sectional area is distributed around its centroid. Once you have the slenderness ratio, you can refer to design codes or standards, such as the American Institute of Steel Construction (AISC) Manual, to find the critical buckling stress or load for the given slenderness ratio. These codes provide tables or formulas to determine the critical buckling capacity based on the angle's dimensions and material properties. It is important to note that the buckling capacity of a steel angle depends on the boundary conditions, end fixity, and the method of buckling, whether it is flexural or torsional. Therefore, understanding the specific loading and boundary conditions is crucial in accurately calculating the buckling capacity.

- Q: How are steel angles supported during installation?

- Steel angles are typically supported during installation by using various techniques and materials. One common method is to use steel brackets or supports that are designed to hold the angles in place. These brackets are often attached to the structure using bolts or screws and provide stability and structural integrity to the angles. Another method of support is to weld the steel angles directly to the structure. This involves using a welding process to fuse the angles to the existing steel framework, ensuring a strong and secure connection. Welding is often preferred in situations where the angles need to bear heavy loads or where additional strength is required. In some cases, steel angles may also be supported using concrete or masonry. This involves embedding the angles into the concrete or masonry structure, providing a solid and stable foundation for the installation. This method is commonly used in construction projects where the angles need to be securely fixed to the building or where additional reinforcement is required. Overall, the specific method of supporting steel angles during installation will depend on the requirements of the project, the load-bearing capacity needed, and the design specifications. It is important to follow the appropriate industry standards and guidelines to ensure a safe and successful installation.

- Q: Can steel angles be bolted together?

- Yes, steel angles can be bolted together. Bolting steel angles is a common method of joining them to create various structures or frameworks.

- Q: Can steel angles be used for framing partitions and walls?

- Yes, steel angles can be used for framing partitions and walls. Steel angles are commonly used in construction for their strength and durability. They can be used to create a framework for partitions and walls by providing structural support and stability. Steel angles are versatile and can be easily cut and welded to fit the desired dimensions and angles. They are also resistant to fire, pests, and moisture, making them a suitable choice for framing interior walls and partitions in both commercial and residential buildings.

Send your message to us

Steel Equal Angle with Good Quality 120*120*8.0-10.0mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords