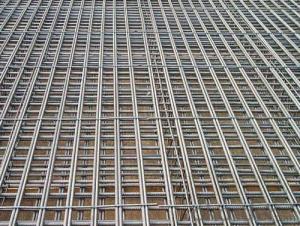

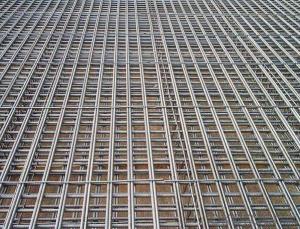

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: steel bar

Weaving: the wires that run parallel to the width of the roll are placed on top of the wires running parallel to the length. Then, the wires are welded where they intersect.

Wire diameter: welded steel bar panels ranges from 5mm to 16mm.

Welded bar panels opening: 75mm to 300mm.

Panel length: 100cm to 1400cm.

Panel width: 100cm to 300cm.

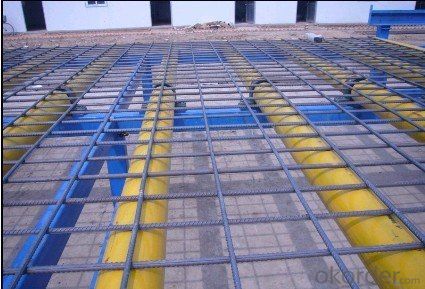

Applications: Welded steel bar panels are widely used in construction reinforcement, the ground for the tunnels, bridges, highway, airport and wharf, also in construction of wall body.

Features: 1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

Packing: 1. Around with Angle steel welded into a bundle

2. Use steel bar tied into a bundle

3. 50-100pcs into a bundle

Special packing can be arranged upon request

- Q: What are the benefits of using steel wire mesh in the automotive manufacturing industry?

- There are several benefits of using steel wire mesh in the automotive manufacturing industry. Firstly, steel wire mesh offers excellent strength and durability. It is capable of withstanding high levels of stress and impact, making it ideal for use in various automotive components such as seat frames, exhaust systems, and reinforcing panels. The strength of steel wire mesh ensures that these components can withstand the harsh conditions of the automotive environment, providing long-lasting performance and reliability. Secondly, steel wire mesh has excellent resistance to corrosion. With the constant exposure to moisture, chemicals, and varying weather conditions, automotive components are prone to rust and deterioration. However, steel wire mesh, often coated with protective finishes, offers exceptional resistance to corrosion. This ensures that the automotive components remain in good condition, prolonging their lifespan and reducing maintenance costs. Additionally, steel wire mesh provides versatility in design and manufacturing. It can be easily molded and shaped into various forms, allowing for the creation of complex automotive parts with intricate designs. This flexibility enables automotive manufacturers to meet the diverse demands of the industry and produce components that are both aesthetically appealing and functional. Furthermore, steel wire mesh offers excellent ventilation and airflow. In automotive applications such as radiator grilles and air intake systems, the use of steel wire mesh allows for efficient air circulation. This enhances the cooling system's performance and helps maintain optimal operating temperatures for the engine and other vital components. Lastly, steel wire mesh provides enhanced safety features. It can be utilized as a protective barrier in vehicles to prevent objects from penetrating the cabin area during accidents. It can also be utilized in the construction of safety belts, ensuring that occupants are securely restrained during collisions, reducing the risk of injury. In conclusion, the benefits of using steel wire mesh in the automotive manufacturing industry include its strength, durability, resistance to corrosion, versatility in design, improved ventilation, and enhanced safety features. These advantages make steel wire mesh a valuable material choice for automotive manufacturers, ultimately contributing to the production of safer and more reliable vehicles.

- Q: How is steel wire mesh used in slope stabilization?

- Steel wire mesh is commonly used in slope stabilization to prevent soil erosion and landslides. It is installed on slopes to provide structural support and reinforcement, preventing the soil from shifting or sliding. The mesh acts as a barrier, holding the soil in place, while still allowing water to flow through, reducing the risk of erosion. Additionally, the steel wire mesh can also be used to anchor vegetation, such as grass or plants, which further helps stabilize the slope and promote soil stability. Overall, steel wire mesh is an effective and versatile solution in slope stabilization, ensuring the safety and stability of the area.

- Q: Does steel wire mesh rust?

- Indeed, steel wire mesh has the capacity to rust. Rust emerges as a consequence of the oxidation procedure which takes place when iron or steel comes into contact with moisture and oxygen. In the event that the steel wire mesh lacks appropriate coating or protection, it becomes vulnerable to rusting as time passes. Nevertheless, there exist diverse techniques to impede or decrease rusting, for instance, by galvanizing the steel wire mesh or administering a safeguarding coating. By implementing these measures, the lifespan of the mesh can be greatly prolonged, guaranteeing its durability.

- Q: What are the different mesh counts available for steel wire mesh?

- Steel wire mesh comes in a range of mesh counts, offering options from very fine to more open weaves. The mesh count indicates the number of openings or holes per linear inch in the mesh screen. For steel wire mesh, the most common mesh counts typically fall between 2 and 400. Coarse mesh counts, below 10, have larger openings and thicker wires, making them suitable for heavy-duty applications like mining screens or fencing. On the other hand, fine mesh counts, above 200, have smaller openings and thinner wires, making them ideal for precise filtration or separation in industries such as pharmaceuticals, food processing, and laboratory testing. Medium mesh counts, ranging from 12 to 100, strike a balance between strength and openness. They are commonly used in applications like filtration, separation, and reinforcement. These mesh counts provide durability while still allowing for adequate airflow or visibility. It is worth noting that the availability of specific mesh counts for steel wire mesh may vary depending on the manufacturer or supplier. Custom mesh counts can also be created to meet specific project requirements.

- Q: How does steel wire mesh perform in terms of visibility and transparency?

- Steel wire mesh performs poorly in terms of visibility and transparency. Due to its dense and tightly woven structure, it obstructs clear visibility and limits the amount of light passing through.

- Q: What are the different wire mesh widths available in steel wire mesh?

- The different wire mesh widths available in steel wire mesh vary depending on the specific application and requirements. Common widths range from 1/4 inch to 4 inches, although custom sizes can also be obtained. It is important to consider the intended use and desired level of filtration or protection when selecting the appropriate wire mesh width.

- Q: Is steel wire mesh easy to clean and maintain?

- Yes, steel wire mesh is generally easy to clean and maintain. It can be easily wiped down or hosed off to remove dirt, dust, or debris. Additionally, its durable and corrosion-resistant nature makes it relatively low-maintenance.

- Q: Can steel wire mesh be used for sunscreens?

- Indeed, sunscreens can make good use of steel wire mesh. This versatile material boasts numerous advantages when employed for such purposes. Its strength and durability render it suitable for outdoor applications, while its mesh structure permits the passage of air and light, providing shade and shielding against the sun's harmful UV rays. Furthermore, steel wire mesh can be easily tailored to accommodate varying sizes and shapes, making it a flexible option for a wide range of sunscreens. Additionally, it is resistant to corrosion and capable of withstanding harsh weather conditions, ensuring its longevity. Nevertheless, it is important to note that steel wire mesh may not be the most visually appealing choice for sunscreens, as it exudes a more industrial aesthetic compared to materials like fabric or PVC.

- Q: Can steel wire mesh be used for creating safety nets or fall protection systems?

- Yes, steel wire mesh can be used for creating safety nets or fall protection systems. Steel wire mesh is durable, strong, and provides a secure barrier that can prevent falls or catch falling objects. It is commonly used in construction, industrial settings, and sports facilities to ensure worker safety and prevent accidents.

- Q: Can steel wire mesh be used for storage racks?

- Yes, steel wire mesh can be used for storage racks. Steel wire mesh is a strong and durable material that can provide excellent support and stability for storing various items. It allows for better visibility and air circulation, making it suitable for storing items that require ventilation or easy access. Additionally, the open design of the mesh allows for easy cleaning and maintenance. Steel wire mesh storage racks are commonly used in industries such as warehousing, retail, and manufacturing, as well as in residential garages or workshops.

Send your message to us

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords