Hot Selling Galvanized Wire Mesh Sheet with Construction Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Galvanized Wire Mesh Sheet Description:

Galvanized Wire Mesh Sheet is a welded wire fabric, prefabricated steel reinforcement material. The fabric is used to provide tensile strength and crack control to structural concrete elements. Smooth and trim mesh surface, solid and uniform structure and superior integral performance, it won't loosen even subject to local cutting or pressure, It has the characteristics of corrosion-resisting and oxidation-resisting.

All cross-points are welded together with strong electric resistance. With high precision, small error and high quality, Galvanized Wire Mesh Sheet is widely used in many sectors, ranging from the ordinary household to heavy industry. It is widely used in housing floor, roof, wall, terrace, concrete pavement, deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian, etc.

2. Main Features of Galvanized Wire Mesh Sheet :

• Durable

• Good Visual

• Convenient

• Widely-use

• Corrosion Resistance

• Sunshine Resistance

3. Galvanized Wire Mesh Sheet Images

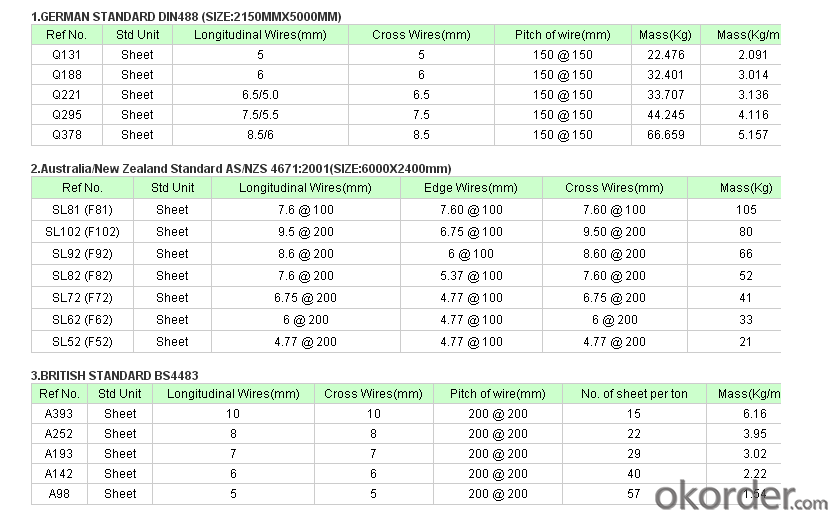

4. Galvanized Wire Mesh Sheet Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Galvanized Wire Mesh Sheet we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products. Our factory covers an area of 14000 square meters and be capable of producing 10000 a day.

②What is Assortments of Galvanized Wire Mesh Sheet ?

Welded Stainless Steel Wire Mesh Panels, Galvanized Welded Mesh Panels; Hot-dip Zinc Plating Welded Mesh Panels.

③How long can we receive the product after purchase?

In the purchase of Galvanized Wire Mesh Sheet within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: What are the different framing options available for steel wire mesh?

- The different framing options available for steel wire mesh include welded frames, woven frames, and frameless options. Welded frames involve the mesh being welded to a metal frame, providing additional stability and strength. Woven frames use interlocking wires to create a frame around the mesh, allowing for flexibility and ease of installation. Frameless options do not have a separate frame and rely on the stiffness of the mesh itself to provide support.

- Q: What is the weight of steel wire mesh?

- The weight of steel wire mesh can vary depending on various factors such as the thickness and diameter of the wire, the size of the mesh openings, and the overall dimensions of the mesh panel. Generally, steel wire mesh is available in different gauges, ranging from light to heavy, with corresponding weights per square foot or square meter. For example, a light gauge steel wire mesh may weigh around 0.5 pounds per square foot (2.45 kilograms per square meter), while a heavy gauge mesh can weigh around 2 pounds per square foot (9.8 kilograms per square meter). It is important to note that these weights are approximate and can vary depending on the specific specifications and manufacturing processes of the steel wire mesh.

- Q: What are the different wire mesh coatings available for steel wire mesh?

- There are several different wire mesh coatings available for steel wire mesh, each offering specific benefits and properties. 1. Galvanized Coating: This is one of the most common and traditional coatings for steel wire mesh. It involves applying a layer of zinc to the surface of the mesh to protect it from corrosion and rust. Galvanized coatings are highly durable and provide excellent resistance to moisture and outdoor elements. 2. PVC Coating: PVC (Polyvinyl Chloride) coating is applied to steel wire mesh to enhance its resistance to corrosion, chemicals, and abrasion. This coating also adds an extra layer of insulation and provides a smooth and attractive finish to the mesh. PVC coated wire mesh is commonly used in applications where aesthetics and protection against harsh environments are important. 3. Epoxy Coating: Epoxy coatings offer superior adhesion and chemical resistance compared to other coatings. They are highly durable and provide excellent protection against corrosion, impact, and abrasion. Epoxy coated wire mesh is commonly used in industrial settings where exposure to chemicals, moisture, and harsh conditions is expected. 4. Polyester Coating: Polyester coatings are known for their excellent resistance to UV radiation, chemicals, and weathering. They provide a smooth and colorful finish to the wire mesh and are often used in architectural applications where aesthetics and durability are essential. 5. Polyethylene Coating: Polyethylene coatings are applied to steel wire mesh to provide protection against corrosion, chemicals, and abrasion. They offer excellent resistance to UV radiation and are commonly used in outdoor applications like fences, enclosures, and animal cages. 6. Stainless Steel Coating: Stainless steel wire mesh does not require any additional coating as it is already highly resistant to corrosion and rust. Stainless steel provides excellent strength and durability, making it suitable for applications that require high strength and hygiene, such as food processing and pharmaceutical industries. It is important to choose the appropriate wire mesh coating based on the specific requirements of the application, such as environmental conditions, desired durability, and aesthetics. Consulting with a wire mesh supplier or expert can help determine the most suitable coating for a particular use.

- Q: How does steel wire mesh perform in terms of light transmission?

- Steel wire mesh does not allow for light transmission as it is a dense and solid material that blocks the passage of light.

- Q: How is steel wire mesh used in reinforcement of airports?

- Steel wire mesh is commonly used in the reinforcement of airports due to its strength, durability, and ability to provide structural support. It is primarily used in concrete applications to enhance the strength and integrity of the airport infrastructure. In airport runways, steel wire mesh is often embedded within the concrete pavement to increase its load-bearing capacity. The mesh acts as a reinforcement, distributing the weight of heavy aircraft and vehicles more evenly across the runway surface. This helps to prevent cracking and rutting, ensuring a smoother and safer landing and takeoff experience for airplanes. Additionally, steel wire mesh is utilized in the construction of airport taxiways, aprons, and parking areas. These areas are subject to high traffic and heavy loads, making them prone to cracking and deterioration over time. By incorporating steel wire mesh into the concrete during construction, the mesh provides an added layer of reinforcement, enhancing the overall strength and durability of these surfaces. Furthermore, steel wire mesh can also be used in the construction of airport perimeter fences and security barriers. The mesh is woven tightly together, creating a strong and secure barrier that helps prevent unauthorized access to sensitive airport areas. This not only enhances the security of the airport but also ensures the safety of passengers and personnel. Overall, the use of steel wire mesh in the reinforcement of airports plays a vital role in maintaining the structural integrity and safety of airport infrastructure. Its ability to withstand heavy loads, prevent cracking, and provide security makes it an essential component in airport construction and maintenance projects.

- Q: How is steel wire mesh used in the telecommunications infrastructure?

- Steel wire mesh is commonly used in the telecommunications infrastructure to provide support and protection to various components. It is used as a reinforcement material in the construction of antenna towers, providing strength and stability to withstand strong winds and other environmental factors. Additionally, steel wire mesh is utilized as a protective barrier around cables and wires, preventing damage from external forces such as vandalism or natural disturbances. Its durability and versatility make steel wire mesh an essential component in the telecommunications industry.

- Q: What are the benefits of using steel wire mesh in the manufacturing industry?

- Steel wire mesh has numerous benefits in the manufacturing industry. Firstly, it provides enhanced strength and durability, making it suitable for demanding applications. It also offers excellent resistance to corrosion and high temperatures, ensuring longevity and reliability. Additionally, steel wire mesh is highly versatile, allowing for easy customization to meet specific requirements. It provides effective filtration and separation, improving product quality. Moreover, its open design allows for better airflow and visibility, promoting safety and efficiency in manufacturing processes. Overall, steel wire mesh is a cost-effective solution that enhances productivity and offers a wide range of benefits in the manufacturing industry.

- Q: What are the benefits of using steel wire mesh in the automotive refurbishing industry?

- Steel wire mesh offers several benefits in the automotive refurbishing industry. Firstly, it provides exceptional strength and durability, making it ideal for applications that require resistance to heavy impacts and wear. Secondly, the mesh acts as a protective barrier, preventing debris and contaminants from damaging the refurbished parts during the painting and finishing processes. Additionally, the open design of the mesh allows for proper ventilation and airflow, ensuring efficient drying and curing of the painted components. Lastly, steel wire mesh is highly versatile and can be easily shaped and molded to fit various automotive parts, making it a cost-effective and reliable option for the industry.

- Q: How is steel wire mesh used in reinforcement of schools?

- Steel wire mesh is commonly used in the reinforcement of schools to enhance structural integrity and ensure safety. It is primarily used in concrete applications, such as floor slabs, walls, and columns. The wire mesh is installed within the concrete to provide additional strength and prevent cracking or breaking under load. In the construction of school buildings, steel wire mesh is typically placed in areas that experience higher stress or require added support, such as staircases, balconies, and areas with heavy foot traffic. This helps distribute the load evenly across the structure, minimizing the risk of structural failure. Moreover, steel wire mesh is also employed in the reinforcement of concrete pavements, patios, and outdoor play areas within the school premises. It strengthens these surfaces, making them more durable and resistant to wear and tear, especially in areas where heavy equipment or vehicles may be used. Additionally, steel wire mesh can be utilized as an alternative to traditional brickwork or masonry in the construction of walls. It provides a cost-effective solution that offers enhanced flexibility, reduced construction time, and improved earthquake resistance. This method is particularly beneficial in regions prone to seismic activity, where the safety of school buildings is of utmost importance. Overall, the use of steel wire mesh in the reinforcement of schools ensures that the structures are robust, long-lasting, and able to withstand the demands of daily use. It plays a vital role in maintaining the safety and structural integrity of school buildings, providing a secure environment for students, teachers, and staff.

Send your message to us

Hot Selling Galvanized Wire Mesh Sheet with Construction Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords