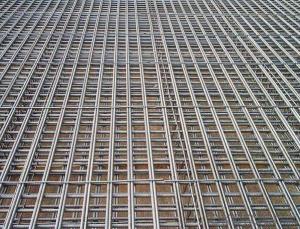

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel bar welded wire mesh Introduction:

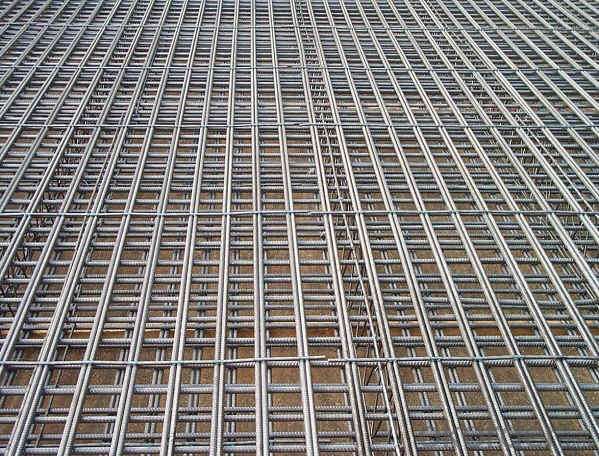

Steel bar welded wire mesh is also called welded steel fabric, steel welding nets, steel welding nets, steel bar welded mesh, steel mesh and so on. Is the longitudinal reinforcement and transverse reinforcement were arranged in a certain interval and at right angles to each other, all the intersections are welded together.

Steel bar wire mesh Description:

Material: low carbon steel bar, thread steel bar, thread rod

1.Mesh width: 0.5 m - 2.4 m;

2.Wire diameter3.0-10.0 (mm);

3.Apertures: 50x50mm,100x100mm,150x150mm,200x200mm

4.length: below 12m

5.Application: construction,bridge,tunnel

6.Mesh size: 6 x2.4m

Product feature:

1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

It is widely use in airport, tunnel, bridge, highway and wharf, also in the construction of building floor, wall, roof and balcony.

Applications:

1. Concrete footpaths

2. Precast Panel construction

3. Construction reinforcement

4. Residential slabs and footings

5. Industrial and commercial ground slabs

Specification:

| WIRE DIAMETER | MESH | |

| Inch | MM | |

| 1.5mm | 1/2" X 1/2" | 12.7mm X 12.7mm |

| 2mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1-1/4" X 1-1/4" | 31.7mm X 31.7mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 2mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 6mm | 4" X 2" | 101.6mm X 50.8mm |

| 6mm | 4" X 4" | 101.6mm X 101.6mm |

Delivery Time:

Within one week for one 20' container.

- Q: Can steel wire mesh be used for architectural elements such as facades?

- Yes, steel wire mesh can be used for architectural elements such as facades. It offers durability, flexibility, and a modern aesthetic, making it suitable for creating unique and visually appealing designs. Additionally, steel wire mesh can provide ventilation, sun shading, and privacy while allowing natural light to pass through.

- Q: What are the different reinforcement patterns available in steel wire mesh?

- The different reinforcement patterns available in steel wire mesh include square mesh, rectangular mesh, diamond mesh, hexagonal mesh, and truss mesh.

- Q: How does the edge finish affect the installation process of steel wire mesh?

- The edge finish of steel wire mesh can greatly impact the installation process. A smooth and clean edge finish allows for easier handling and manipulation of the mesh during installation. It reduces the risk of injuries or damage to the mesh or surrounding structures. On the other hand, a rough or jagged edge finish can make it more challenging to align and secure the mesh properly, potentially leading to uneven or unstable installation. Therefore, a good edge finish is crucial for a smooth and efficient installation process of steel wire mesh.

- Q: What are the safety considerations when working with steel wire mesh?

- There are several safety considerations that must be taken into account when working with steel wire mesh. 1. Personal Protective Equipment (PPE) is essential for protecting oneself from potential hazards. It is important to wear appropriate gear, such as gloves, safety glasses, and steel-toed boots. Steel wire mesh can have sharp edges or protruding ends that may cause cuts or punctures, and gloves can help prevent such injuries. 2. Proper handling and lifting techniques must be used when dealing with heavy and cumbersome steel wire mesh. It is crucial to use the correct equipment and lifting methods when moving or transporting it. For larger and heavier pieces, team lifting may be necessary to avoid strain or injury. 3. To ensure safe installation, the steel wire mesh must be adequately secured. This can be done by using appropriate fasteners or supporting structures to prevent shifting or falling. Failure to secure the mesh properly can result in accidents or injuries. 4. Before working with steel wire mesh, it is important to inspect it for sharp edges or protruding ends that can cause cuts or punctures. If any hazards are identified, they should be addressed or removed before proceeding. 5. Welding steel wire mesh may be necessary in some cases. However, welding poses its own set of safety considerations, including the risk of burns, eye injuries from arc flash, and fumes or gases emitted during the process. Proper safety measures, such as ventilation, welding screens, and welding helmets, should be employed to protect against these hazards. 6. The structural integrity of the steel wire mesh is crucial, especially when used for support or reinforcement. It is important to ensure that the mesh is in good condition and meets the required specifications for load-bearing capacity. Any signs of damage or weakness should be promptly addressed to maintain structural integrity and prevent accidents or collapses. 7. All workers involved in working with steel wire mesh should undergo proper training on safe handling, installation, and maintenance. They should be aware of the potential hazards associated with this material and how to mitigate them. Regular safety briefings and reminders can help reinforce these practices. By following these safety considerations, workers can minimize the risk of accidents or injuries when working with steel wire mesh. Safety should always be prioritized to create a secure working environment.

- Q: What are the advantages of using steel wire mesh in construction?

- There are several advantages of using steel wire mesh in construction. Firstly, steel wire mesh provides high tensile strength and durability, making it suitable for reinforcing concrete structures and enhancing their structural integrity. Additionally, steel wire mesh offers excellent resistance to corrosion, ensuring the longevity of the construction project. It also provides a cost-effective solution due to its ease of installation and low maintenance requirements. Moreover, steel wire mesh allows for better load distribution and reduces cracking in concrete, resulting in improved overall performance. Lastly, steel wire mesh is highly versatile, allowing it to be customized to fit various construction needs, such as reinforcing walls, slabs, and foundations.

- Q: How does steel wire mesh perform in terms of airflow?

- Steel wire mesh performs well in terms of airflow due to its open design. The interwoven pattern of the wires allows air to pass through the mesh easily, facilitating good ventilation. This makes it an ideal material for applications where airflow is crucial, such as air filtration systems, ventilation panels, and screens for windows or doors. The open structure of steel wire mesh ensures that there is minimal resistance to the passage of air, providing efficient airflow while still maintaining its structural integrity.

- Q: How does steel wire mesh perform in high-pressure applications?

- Due to its inherent strength and durability, steel wire mesh proves itself as a reliable performer in high-pressure applications. Its tightly woven structure enables it to withstand and evenly distribute pressure, thus rendering it highly resistant to deformation or failure even in the face of extreme pressures. Moreover, steel wire mesh exhibits the ability to retain its structural integrity even when subjected to harsh environmental conditions or fluctuations in temperature. Consequently, it emerges as an optimal selection for high-pressure applications like filtration systems, hydraulic systems, and industrial processes that demand dependable and consistent performance under intense pressure.

- Q: How does steel wire mesh perform in terms of UV resistance?

- Steel wire mesh typically has low resistance to UV radiation. Over time, prolonged exposure to UV rays can cause the steel wire mesh to weaken and deteriorate. This is because the UV rays can break down the protective coatings on the mesh, leading to corrosion and eventually compromising its structural integrity. To prevent or minimize the effects of UV radiation, steel wire mesh can be treated with specialized coatings or paints that provide additional UV resistance. However, it is important to note that even with these protective measures, prolonged exposure to UV rays can still cause some level of degradation to the steel wire mesh. Therefore, if UV resistance is a critical factor, alternative materials such as plastic or fiberglass mesh may be more suitable for the intended application.

- Q: Can steel wire mesh be used for industrial applications?

- Yes, steel wire mesh can definitely be used for industrial applications. Steel wire mesh is a versatile and durable material that can withstand high temperatures, heavy loads, and harsh environments. It is commonly used in various industries such as construction, mining, agriculture, manufacturing, and transportation. In construction, steel wire mesh is used for reinforcing concrete structures, providing strength and stability. It can also be used in fencing and security applications to create barriers and enclosures. In the mining industry, steel wire mesh is used for screening, sorting, and separating materials. It is also used for filtration purposes in oil and gas industries. Furthermore, steel wire mesh finds applications in the agricultural sector, where it is used for animal enclosures, bird cages, and crop protection. In manufacturing, steel wire mesh is used for sieving, filtering, and straining processes. It can be used as conveyor belts or as support structures in machinery and equipment. The transportation industry also relies on steel wire mesh for various purposes. It is used in the manufacturing of automotive parts, such as filters and grilles. It is also used for cargo containment in trucks and trailers. Overall, steel wire mesh is highly versatile and can be customized to meet specific industrial requirements. Its strength, durability, and flexibility make it a preferred choice for industrial applications in a wide range of industries.

- Q: Can steel wire mesh be used for gabion planters?

- Indeed, gabion planters can utilize steel wire mesh. These planters are essentially containers made from wire mesh that are filled with stones or other materials, and they serve as a medium for planting a wide array of vegetation. The reason why steel wire mesh is frequently employed in constructing gabion planters is because of its durability and strength. It offers a robust framework that securely holds the stones in position, all the while permitting water to drain through. Furthermore, steel wire mesh is resistant to corrosion, which renders it suitable for outdoor usage. All in all, steel wire mesh emerges as a dependable and practical option for the creation of gabion planters.

Send your message to us

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords