Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforcing wire mesh is a welded wire fabric, prefabricated steel reinforcement material.

The fabric is used to provide tensile strength and crack control to structural concrete elements.

Specifications

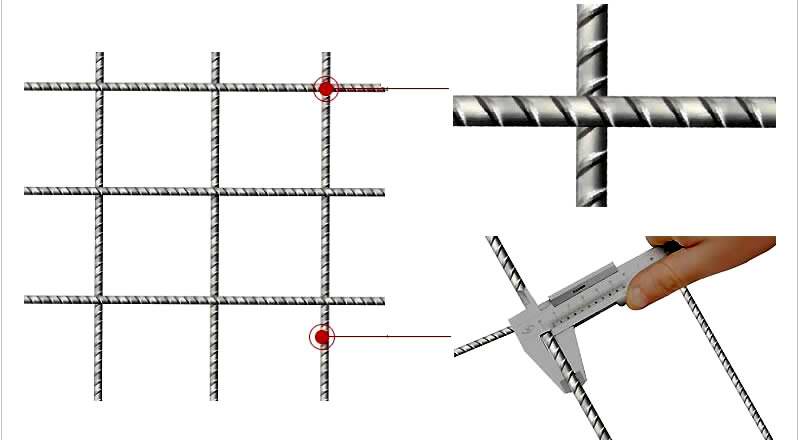

Wire diameter: 3mm to 12mm

Line wire spacing: min100 mm. larger line wire spacing in steps of 50 mm

Cross wire spacing: min 25mm. above programmable in increments of 0.1 mm

Wire mesh length: 500- 12000 mm

Wire mesh width: 500- 3300 mm

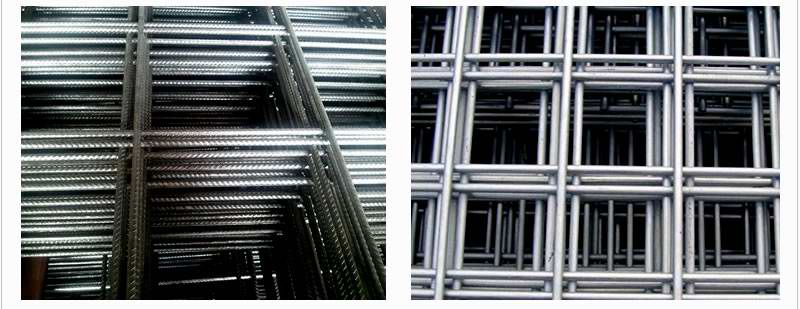

It's made of Deformed Steel Bars or Steel Rod.

Specification of Reinforcing Mesh

DIN488 GERMAN STANDARD (SIZE:2150MMX5000MM)

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | Mass Kg | Mass Kg/m2 |

| Q131 | Sheet | 5 | 5 | 150 @ 150 | 22.476 | 2.091 |

| Q188 | Sheet | 6 | 6 | 150 @ 150 | 32.401 | 3.014 |

| Q221 | Sheet | 6.5/5.0 | 6.5 | 150 @ 150 | 33.707 | 3.136 |

| Q295 | Sheet | 7.5/5.5 | 7.5 | 150 @ 150 | 44.245 | 4.116 |

| Q378 | Sheet | 8.5/6 | 8.5 | 150 @ 150 | 66.659 | 5.157 |

AS/NZS 4671:2001 Australia/New Zealand Standard (SIZE:6000X2400mm)

| Ref No. | Std Unit | Longitudinal Wires mm | Edge Wires mm | Cross Wires mm | Mass Kg |

| SL81 (F81) | Sheet | 7.6 @ 100 | 7.60 @ 100 | 7.60 @ 100 | 105 |

| SL102 (F102) | Sheet | 9.5 @ 200 | 6.75 @ 100 | 9.50 @ 200 | 80 |

| SL92 (F92) | Sheet | 8.6 @ 200 | 6 @ 100 | 8.60 @ 200 | 66 |

| SL82 (F82) | Sheet | 7.6 @ 200 | 5.37 @ 100 | 7.60 @ 200 | 52 |

| SL72 (F72) | Sheet | 6.75 @ 200 | 4.77 @ 100 | 6.75 @ 200 | 41 |

| SL62 (F62) | Sheet | 6 @ 200 | 4.77 @ 100 | 6 @ 200 | 33 |

| SL52 (F52) | Sheet | 4.77 @ 200 | 4.77 @ 100 | 4.77 @ 200 | 21 |

BS4483 BRITISH STANDARD

| Ref No. | Std Unit | Longitudinal Wires mm | Cross Wires mm | Pitch of wire | No. of sheet per ton | Mass Kg/m2 |

| A393 | Sheet | 10 | 10 | 200 @ 200 | 15 | 6.16 |

| A252 | Sheet | 8 | 8 | 200 @ 200 | 22 | 3.95 |

| A193 | Sheet | 7 | 7 | 200 @ 200 | 29 | 3.02 |

| A142 | Sheet | 6 | 6 | 200 @ 200 | 40 | 2.22 |

| A98 | Sheet | 5 | 5 | 200 @ 200 | 57 | 1.54 |

Application

1. surface beds (concrete floor slabs on fill) and concrete roads

2. suspended floor slabs, concrete walls, culverts / drains and composite brick / concrete retaining walls

Packaging & Delivery

| Packaging Details: | 1. Around with Angle steel welded into a bundle 2. Use steel bar tied into a bundle 3. 50-100pcs into a bundle |

| Delivery Detail: | 7-15days after received the deposit. |

- Q: How is steel wire mesh used in the aviation industry?

- Due to its strength, durability, and lightweight properties, steel wire mesh finds extensive use in the aviation industry. The construction of aircraft engine filters is one primary application of this material. These filters are responsible for removing air particles and contaminants that enter the engine. Steel wire mesh is used as the filtering medium because of its effective trapping and holding capabilities, preventing these particles from causing any harm. Moreover, steel wire mesh is utilized in the production of aircraft cargo nets. These nets secure and contain cargo during flight, ensuring it remains stable even during turbulent or abrupt maneuvers. The high tensile strength of steel wire mesh makes it an ideal choice for these nets, as it can withstand the forces exerted during flight without breaking or tearing. Furthermore, steel wire mesh is also involved in the assembly of aircraft interior components, including partitions and barriers. These components provide structural support and divide the interior space into different sections. Steel wire mesh panels are commonly used for these purposes due to their lightweight nature, which contributes to minimizing the overall weight of the aircraft without compromising its strength or safety. In conclusion, steel wire mesh is an essential material in the aviation industry, offering strength, durability, and lightweight properties in various applications. Whether it's engine filters, cargo nets, or interior components, this versatile material contributes significantly to the safety and efficiency of aircraft operations.

- Q: What are the benefits of using steel wire mesh in the automotive recycling industry?

- There are several benefits of using steel wire mesh in the automotive recycling industry. Firstly, steel wire mesh provides strong and durable containment for various types of materials, ensuring that they are securely transported and stored. It also allows for proper ventilation and drainage, preventing the accumulation of moisture or other potentially damaging elements. Additionally, steel wire mesh is highly resistant to corrosion and wear, making it a long-lasting and cost-effective solution. It can be easily cleaned and maintained, reducing the risk of contamination. Lastly, steel wire mesh is malleable, allowing for customization and flexibility to meet specific industry needs.

- Q: What are the acoustic properties of steel wire mesh?

- Various factors, such as wire diameter, wire spacing, and mesh thickness, can influence the acoustic properties of steel wire mesh. Generally, steel wire mesh is known for its favorable sound transmission abilities due to its open structure. This enables sound waves to pass through, making it suitable for applications that require even sound distribution, like speaker grills and sound diffusion panels. However, steel wire mesh also possesses sound reflection and absorption characteristics. When sound waves encounter the mesh, some of the sound energy is bounced back, while some is absorbed by the mesh itself. The degree of reflection and absorption relies on the specific design and attributes of the mesh. Moreover, the acoustic properties of steel wire mesh can be influenced by its thickness. Thicker mesh typically exhibits greater sound absorption capabilities compared to thinner mesh, as it has more mass and surface area for sound energy dissipation. In conclusion, steel wire mesh offers a well-balanced combination of sound transmission, reflection, and absorption properties, making it a versatile material for various acoustic applications. However, it is important to evaluate the unique design and specifications of a steel wire mesh product to determine its specific acoustic performance.

- Q: Can steel wire mesh be used for industrial sieving?

- Yes, steel wire mesh can be used for industrial sieving. Steel wire mesh is a versatile and durable material that is commonly used in sieving applications across various industries. It is specifically designed to withstand heavy use and provide accurate and efficient sieving of materials. Steel wire mesh is known for its high strength and resistance to abrasion, making it ideal for industrial sieving where there is a need to separate particles of different sizes. It can effectively retain larger particles while allowing smaller particles to pass through, ensuring the desired sieving results. Additionally, steel wire mesh is available in different weave patterns and mesh sizes, allowing for customization based on specific sieving requirements. It can be woven in various configurations such as square, rectangular, or diamond-shaped openings, providing flexibility to suit different industrial applications. Moreover, steel wire mesh can withstand high temperatures and harsh environments, making it suitable for sieving applications that involve abrasive materials or extreme conditions. It is commonly used in industries such as mining, construction, pharmaceuticals, food processing, and agriculture, among others. In summary, steel wire mesh is a reliable and efficient material for industrial sieving due to its strength, durability, and versatility. Its ability to separate particles of different sizes accurately makes it an essential component in many industrial processes.

- Q: What are the different edge treatments available for steel wire mesh?

- There are several different edge treatments available for steel wire mesh, each serving a specific purpose and providing unique benefits. One common edge treatment is the selvage edge, which is created by looping the wire strands back into the mesh. This creates a reinforced edge that helps to prevent unraveling or fraying of the mesh. Selvage edges are often used in applications where the mesh will be subjected to high tension or stress, such as in fencing or industrial applications. Another edge treatment option is the knuckled edge, where the wire strands are bent back in a gentle curve. This type of edge is commonly found in chain link fencing and provides a safe and smooth edge, reducing the risk of injury when coming into contact with the mesh. The knuckled edge also helps to prevent snagging or tearing of clothing or other materials. For applications that require a more rigid and secure edge, a barbed or twisted edge can be used. This involves bending the wire strands at the edge into sharp barbs or twists, providing additional security and preventing unauthorized access or tampering. Barbed or twisted edges are often used in high-security fencing or perimeter protection systems. In some cases, a reinforced edge treatment may be necessary to provide extra strength and durability to the mesh. This can involve adding an additional layer of wire or a metal strip along the edge, increasing the overall stability and preventing deformation or sagging. Overall, the choice of edge treatment for steel wire mesh will depend on the specific application and requirements. It is important to consider factors such as strength, safety, durability, and aesthetics when selecting the appropriate edge treatment. Consulting with a knowledgeable supplier or manufacturer can help determine the best edge treatment for a particular project.

- Q: Can steel wire mesh be used for creating mesh containers?

- Yes, steel wire mesh can be used for creating mesh containers. Steel wire mesh is known for its strength, durability, and ability to withstand heavy loads, making it an ideal material for constructing mesh containers. The mesh design allows for easy visibility and ventilation, making it suitable for storing and transporting various items such as produce, tools, and equipment. Additionally, steel wire mesh containers can be stacked efficiently, saving space in storage or during transportation.

- Q: Is steel wire mesh resistant to discoloration?

- Steel wire mesh is generally resistant to discoloration. Steel itself is a highly durable and corrosion-resistant material, making it less prone to discoloration compared to other materials. However, it is important to note that discoloration can still occur under certain circumstances. Exposure to harsh chemicals, extreme temperatures, or prolonged exposure to moisture can potentially cause discoloration or oxidation of the steel wire mesh. Regular maintenance and cleaning can help mitigate the risk of discoloration and ensure the longevity of the steel wire mesh's appearance.

- Q: What are the common uses of steel wire mesh in construction?

- Steel wire mesh is commonly used in construction for a variety of purposes. One of the main uses of steel wire mesh is in concrete reinforcement. The mesh is placed within the concrete to provide additional strength and support, preventing cracks and improving the overall durability of the structure. This is particularly important in areas where the concrete will be subjected to heavy loads or potential impacts. Another common use of steel wire mesh in construction is in the creation of barriers and fences. The mesh can be used to create secure enclosures, such as animal pens or safety barriers around construction sites. It provides a strong and secure boundary, while still allowing visibility and airflow. Steel wire mesh is also used in construction for its ability to provide a level of protection and safety. It can be used to cover openings or gaps in structures, preventing the entry of debris, animals, or unauthorized individuals. Additionally, steel wire mesh can be used as a safety measure on windows or balconies, preventing falls and ensuring the well-being of occupants. In some cases, steel wire mesh is used for decorative purposes in construction. It can be used as a design element in walls, ceilings, and facades, adding texture and visual interest to the structure. The mesh can also be used as a support for climbing plants, creating a green and natural aesthetic. Overall, steel wire mesh is a versatile material that finds numerous applications in construction. Its strength, durability, and flexibility make it an ideal choice for reinforcing concrete, creating barriers, providing safety, and adding decorative elements to buildings and structures.

- Q: What are the safety considerations when working with steel wire mesh?

- When working with steel wire mesh, there are several safety considerations that need to be taken into account. 1. Personal Protective Equipment (PPE): It is important to wear the appropriate PPE, such as gloves, safety glasses, and steel-toed boots, to protect oneself from potential hazards. Steel wire mesh can have sharp edges or protruding ends that may cause cuts or punctures, and gloves can help prevent such injuries. 2. Handling and lifting: Steel wire mesh can be heavy and cumbersome to handle, so it is crucial to use proper lifting techniques and equipment when moving or transporting it. Team lifting may be necessary for larger and heavier pieces to avoid strain or injury. 3. Secure installation: When installing steel wire mesh, it is essential to ensure that it is adequately secured to prevent it from shifting or falling. This may involve using appropriate fasteners or supporting structures to maintain stability. Failing to secure the mesh properly can lead to accidents or injuries. 4. Sharp edges and protruding ends: Steel wire mesh may have sharp edges or protruding ends that can cause cuts or punctures. It is important to inspect the mesh for any sharp or jagged edges before working with it. If any such hazards are identified, they should be addressed or removed before proceeding. 5. Welding hazards: In some cases, steel wire mesh may need to be welded or joined together. Welding poses its own set of safety considerations, such as the risk of burns, eye injuries from arc flash, and fumes or gases emitted during the process. Proper ventilation, welding screens, and welding helmets should be used to protect against these hazards. 6. Structural integrity: Steel wire mesh is often used for structural support or reinforcement. It is crucial to ensure that the mesh is in good condition and meets the required specifications for load-bearing capacity. Any signs of damage or weakness should be addressed promptly to maintain the structural integrity and prevent accidents or collapses. 7. Training and awareness: All workers involved in working with steel wire mesh should receive proper training on its safe handling, installation, and maintenance. They should be aware of the potential hazards associated with this material and how to mitigate them. Regular safety briefings and reminders can help reinforce these practices. By following these safety considerations, workers can minimize the risk of accidents or injuries when working with steel wire mesh. It is crucial to prioritize safety at all times to create a secure working environment.

- Q: Can steel wire mesh be used for creating mesh panels or fences?

- Yes, steel wire mesh can be used for creating mesh panels or fences. Steel wire mesh is commonly used in construction and industrial applications due to its durability and strength. It provides a secure and effective barrier for various purposes, including fencing and creating mesh panels.

Send your message to us

Concrete Reinforcing Welded Wire Mesh / Trench mesh / steel concrete mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords