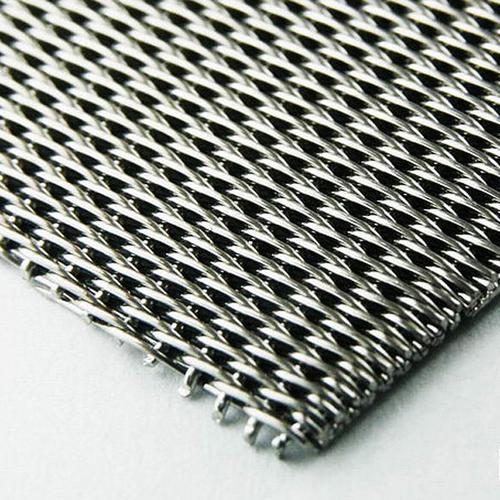

Stainless Steel Reverse Dutch Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

For Dutch weaves micron-grade wireis most commonly used. In addition, FLS has the capability to manufacture:

HighTensile Warp wire for Auto-Screen changers used in the Plastic ExtrusionIndustry.

RubbedEdges after slitting to help with tracking for Auto-Screen changers.

Plasma andlaser cut parts to help prevent edges wire fraying.

100%Inspection of Wire Cloth for critical applications such as sand screens andaerospace applications.

We offer a wide range of metals and alloys to provide thebest material or combination of materials for the filter mesh. Contact us todayfor more information or a detailed quote.

Standard Specs

WEAVE TYPE | MESH COUNT | WARP WIRE | SHUTE WIRE |

RDPW | 45x15 | 0.45 | 0.6 |

RDPW | 72x15 | 0.45 | 0.55 |

RDPW | 120x16 | 0.35 | 0.45 |

RDPW | 132x17 | 0.3 | 0.45 |

RDPW | 152x24 | 0.3 | 0.4 |

RDPW | 160x18 | 0.28 | 0.45 |

RDPW | 200x40 | 0.15 | 0.27 |

RDPW | 260x40 | 0.15 | 0.27 |

RDPW | 300x40 | 0.15 | 0.27 |

RDPW | 350x40 | 0.13 | 0.27 |

- Q: When will the masonry be hung?

- Last year I met a 32-story project, in order to prevent the top two layers of external walls cracking and seepage, the top two layers of external walls full of wire mesh, the effect is very good.

- Q: Can steel wire mesh be used for insect screens?

- Yes, steel wire mesh can be used for insect screens. Steel wire mesh is a durable and strong material that can effectively prevent insects from entering a space while allowing for proper ventilation. It is commonly used for windows, doors, and other openings to keep insects out while still allowing fresh air to circulate. Steel wire mesh is resistant to rust and corrosion, making it suitable for outdoor applications. Additionally, it is available in different mesh sizes to accommodate various types of insects, ensuring effective protection against pests.

- Q: Can steel wire mesh be used for mining?

- Yes, steel wire mesh can be used for mining. It is commonly used in various mining applications due to its strength, durability, and versatility. Steel wire mesh is often used as a protective barrier in underground mines to prevent loose rocks or debris from falling onto workers or equipment. It is also used as a reinforcement material in mining tunnels and shafts to provide additional structural support. Additionally, steel wire mesh can be used to separate and classify different sizes of minerals or ores during the extraction process. Its high tensile strength and resistance to corrosion make it an ideal choice for mining operations, where harsh conditions and heavy loads are common.

- Q: Can steel wire mesh be used for soundproofing?

- No, steel wire mesh alone is not effective for soundproofing as it does not provide sufficient sound insulation.

- Q: What are the different mesh counts available for steel wire mesh?

- There are various mesh counts available for steel wire mesh, ranging from very fine to more open weaves. The mesh count refers to the number of openings or holes per linear inch in the mesh screen. The most common mesh counts for steel wire mesh are typically between 2 and 400. Mesh counts below 10 are considered coarse, while those above 200 are considered fine. Coarse mesh counts, such as 2 to 10, have larger openings and thicker wires, making them suitable for heavy-duty applications like mining screens or fencing. Medium mesh counts, ranging from 12 to 100, are commonly used in applications like filtration, separation, and reinforcement. These mesh counts strike a balance between strength and openness, providing durability while still allowing for adequate airflow or visibility. Fine mesh counts, from 120 to 400, are ideal for applications requiring precise filtration or separation. They have smaller openings and thinner wires, offering excellent particle retention capabilities. Fine steel wire mesh is often used in industries such as pharmaceuticals, food processing, and laboratory testing. It is important to note that the specific mesh counts available for steel wire mesh may vary depending on the manufacturer or supplier. Additionally, custom mesh counts can be made to suit specific project requirements.

- Q: How does steel wire mesh perform in radiation shielding applications?

- Steel wire mesh can be an effective material for radiation shielding applications due to its dense structure and high atomic number. It can attenuate and scatter radiation, reducing its intensity and protecting against harmful effects. Additionally, steel wire mesh is durable, easy to install, and cost-effective, making it a popular choice in various industries requiring radiation shielding.

- Q: What are the different grades of steel used for wire mesh?

- There are several different grades of steel that are commonly used for wire mesh, each with its own unique properties and applications. One of the most commonly used grades of steel for wire mesh is stainless steel. Stainless steel wire mesh is highly durable and resistant to corrosion, making it an ideal choice for applications that require strength and longevity, such as industrial filtration, food processing, and architectural applications. Another grade of steel commonly used for wire mesh is galvanized steel. Galvanized steel wire mesh is coated with a layer of zinc, which provides excellent corrosion resistance. This grade of steel is often used in outdoor applications where exposure to moisture and harsh weather conditions is a concern, such as fencing, animal enclosures, and agricultural applications. Carbon steel is another grade of steel that is commonly used for wire mesh. Carbon steel wire mesh is known for its high tensile strength and durability, making it suitable for heavy-duty applications such as mining, construction, and industrial sieving. In addition to these common grades, there are also specialized grades of steel used for specific applications. For example, spring steel wire mesh is made from high-carbon steel and is known for its flexibility and ability to withstand high tension. This type of wire mesh is often used in industries such as automotive, aerospace, and electronics. Overall, the choice of grade for wire mesh depends on the specific requirements of the application, including factors such as corrosion resistance, strength, flexibility, and durability. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable grade of steel for your wire mesh needs.

- Q: How is steel wire mesh used in the marine industry?

- Steel wire mesh is widely used in the marine industry for various applications due to its strength, durability, and resistance to corrosion. One of the primary uses of steel wire mesh in this industry is for coastal and offshore protection. It is commonly used to create robust barriers, such as breakwaters and revetments, that help protect shorelines from erosion caused by tides, waves, and storms. The mesh acts as a reinforcement, providing stability and preventing soil or sand from being washed away. Steel wire mesh is also utilized in marine construction projects, such as the building of piers, jetties, and seawalls. It is used as a formwork, providing temporary support during the pouring of concrete. The mesh acts as a reinforcement within the concrete structure, enhancing its strength and preventing cracking or deformation. Another important application of steel wire mesh in the marine industry is in the creation of fish farms and aquaculture systems. The mesh is used to create cages or enclosures that hold fish or other marine organisms, allowing them to be farmed or bred in controlled environments. The mesh is strong enough to withstand the forces of the water while also allowing water to flow freely, ensuring proper oxygenation for the fish. Furthermore, steel wire mesh is used in the marine industry for safety and security purposes. It is commonly employed as fencing or barriers around ports, harbors, and shipyards to restrict unauthorized access and protect valuable assets. The mesh provides a high level of visibility while still maintaining a strong physical barrier. In summary, steel wire mesh is a versatile material extensively used in the marine industry. Its applications range from coastal protection and marine construction to aquaculture systems and security fencing. The strength, durability, and resistance to corrosion make it an ideal choice for various marine-related projects.

- Q: Can steel wire mesh be used for waste bins?

- Yes, steel wire mesh can indeed be used for waste bins. Steel wire mesh is a versatile material that offers several benefits when used for waste bins. Firstly, its sturdy construction ensures durability and longevity, making it suitable for heavy-duty use in waste management applications. Additionally, the open design of the mesh allows for proper ventilation, preventing the buildup of odors and reducing the risk of bacterial growth. The holes in the mesh also allow for easy visibility of the waste content, making it easier to identify and sort recyclable materials. Furthermore, steel wire mesh is resistant to rust and corrosion, making it suitable for both indoor and outdoor use. Overall, steel wire mesh is a practical and functional choice for waste bins, providing strength, ventilation, and visibility.

- Q: How is steel wire mesh used in the automotive aftermarket industry?

- Steel wire mesh is commonly used in the automotive aftermarket industry for various purposes such as reinforcing car grilles, protecting radiators and intercoolers, enhancing the aesthetic appearance of vehicles, and providing additional safety measures by securing headlights and taillights.

Send your message to us

Stainless Steel Reverse Dutch Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords