Steel Sheets Steel Plates Made In China Hot Rolled Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

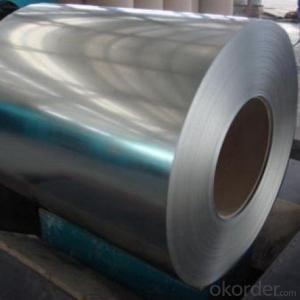

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

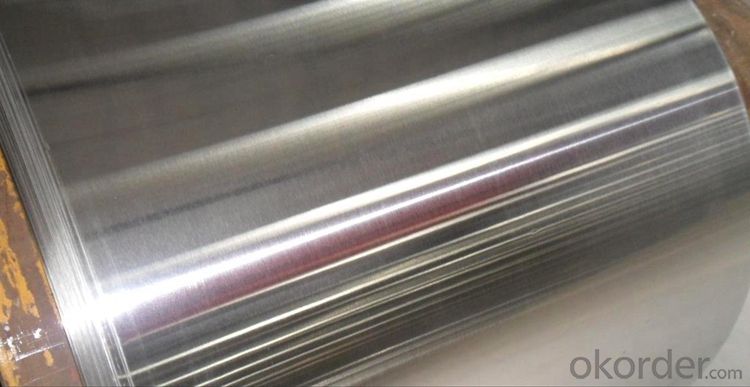

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for storage cabinets. Stainless steel sheets are able to withstand heavy loads and can resist damage from moisture, heat, and chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storage cabinets. Overall, stainless steel sheets provide a long-lasting and reliable solution for storage cabinets in various environments such as kitchens, laboratories, and industrial settings.

- Q: Can stainless steel sheets be used for filtration applications?

- Stainless steel sheets are indeed capable of being utilized in filtration applications. Renowned for its resistance to corrosion and enduring nature, stainless steel proves to be an exceptional option for filtration systems. To cater to diverse filtration requirements, these sheets can be shaped into a variety of filter elements like screens, discs, or cartridges. Their mechanical strength is of a high caliber, enabling them to withstand substantial pressures and temperatures without experiencing deformation. Furthermore, stainless steel can be effortlessly cleansed and sanitized, rendering it suitable for situations where hygiene holds utmost importance, such as within the food and beverage industry. All in all, owing to their impressive performance and dependability, stainless steel sheets are extensively employed in filtration applications.

- Q: Are stainless steel sheets available in different finishes?

- Indeed, there are various finishes in which stainless steel sheets are available. Stainless steel is a highly adaptable substance that can be finished in diverse manners for distinct visual and textural effects. Among the frequently used finishes are brushed, mirror, satin, and textured finishes. Each finish possesses its own distinctive aesthetic charm and can be selected according to the desired appearance and particular application demands. Moreover, the chosen finish can also influence the resistance of the stainless steel sheets against corrosion, staining, and scratching. Consequently, manufacturers provide an array of finishes to accommodate different customer preferences and specific project requirements.

- Q: Are stainless steel sheets suitable for outdoor furniture?

- Yes, stainless steel sheets are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability and resistance to corrosion, making it an ideal material for withstanding outdoor elements such as rain, sunlight, and temperature changes. Stainless steel sheets are also easy to clean and maintain, requiring minimal effort to keep them looking new. Additionally, stainless steel has a sleek and modern appearance that can enhance the aesthetic appeal of outdoor furniture. Overall, stainless steel sheets offer the perfect combination of strength, longevity, and visual appeal, making them a great choice for outdoor furniture.

- Q: What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on factors such as size, thickness, and grade of stainless steel. Generally, stainless steel sheets can range from $20 to $200 per sheet, but prices can be higher for specialized or custom-made sheets.

- Q: Are stainless steel sheets suitable for petrochemical refineries?

- Yes, stainless steel sheets are suitable for petrochemical refineries. Stainless steel has excellent corrosion resistance, high strength, and can withstand high temperatures, making it ideal for the harsh and corrosive environments present in petrochemical refineries.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- There are several different types of stainless steel sheet finishes that are commonly used in automotive applications. These finishes are designed to provide both aesthetic appeal and functional benefits for the automotive industry. 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a rough, dull appearance. It is commonly used in non-decorative applications where corrosion resistance is the primary concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is commonly used for automotive trim and decorative applications. It has a smooth surface and a moderate level of reflectivity. 3. No. 3 Finish: This is a semi-polished finish that is achieved by using progressively finer abrasives. It has a moderate level of reflectivity and is commonly used for decorative applications where a shinier appearance is desired. 4. No. 4 Finish: This is a brushed finish that is achieved by polishing the stainless steel sheet with a fine-grit abrasive. It has a consistent, linear grain pattern and a moderate level of reflectivity. It is commonly used for decorative applications such as trim and accents. 5. No. 8 Mirror Finish: This is a highly polished finish that is achieved by buffing the stainless steel sheet with a series of abrasive compounds. It has a mirror-like appearance and is commonly used for decorative applications that require a high level of reflectivity. In addition to these standard finishes, there are also specialty finishes available for automotive applications, such as embossed, patterned, or textured finishes. These finishes can provide unique design elements and enhance the overall aesthetic appeal of the vehicle. Overall, the choice of stainless steel sheet finish for automotive applications depends on the specific requirements of the project, including factors such as corrosion resistance, durability, and desired appearance.

- Q: What is the fire resistance rating of stainless steel sheets?

- Stainless steel sheets lack an inherent fire resistance rating as they are not naturally fire resistant materials. Nevertheless, stainless steel can demonstrate commendable fire resistance attributes due to its high melting point and low thermal conductivity. Consequently, stainless steel sheets are less prone to melting or transferring heat during a fire, thus impeding the spread of flames. Furthermore, stainless steel possesses corrosion resistance, which further bolsters its performance in fire scenarios. However, it should be emphasized that the fire resistance of a structure or system hinges on a combination of diverse factors, encompassing the comprehensive design, construction, and utilization of fire-resistant materials. Consequently, the fire resistance rating of stainless steel sheets may fluctuate depending on the specific application and the overarching fire protection measures implemented.

- Q: How is stainless steel different from other types of steel?

- Stainless steel possesses distinct characteristics and composition that differentiate it from other steel types. Its composition includes a minimum of 10.5% chromium, which forms a thin, imperceptible layer of chromium oxide on the surface. This layer's exceptional resistance to corrosion grants stainless steel exceptional durability. When compared to other steel varieties, stainless steel resists rust, staining, and corrosion when exposed to moisture, air, or chemicals. This corrosion resistance makes it ideal for applications in environments notorious for harsh conditions, such as kitchen appliances, cutlery, medical equipment, and construction materials. Additionally, stainless steel offers remarkable strength and durability, making it an excellent choice for applications requiring high structural integrity. Furthermore, it exhibits heat resistance, retaining its strength and shape even at elevated temperatures. This quality renders stainless steel widely used in industries like automotive, aerospace, and construction. Furthermore, stainless steel's non-porous surface and resistance to bacterial growth contribute to its high level of hygiene. It is easy to clean and maintain, making it highly favored for food processing equipment, medical instruments, and sanitary applications. To summarize, stainless steel distinguishes itself from other steel types due to its corrosion resistance, strength, heat resistance, and hygienic properties. These attributes render it a versatile material utilized across various industries and applications, where durability, longevity, and resistance to external factors prove essential.

- Q: What does 8K stainless steel mean?

- The stainless steel mirror panel is polished by polishing the surface of BA, 2B or No.1 on an initial surface like a mirror surface (8K, mirror or No.8).

Send your message to us

Steel Sheets Steel Plates Made In China Hot Rolled Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords