Stainless Steel Coils/Sheets/Plates Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

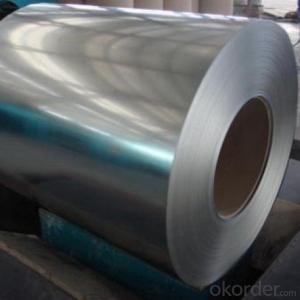

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

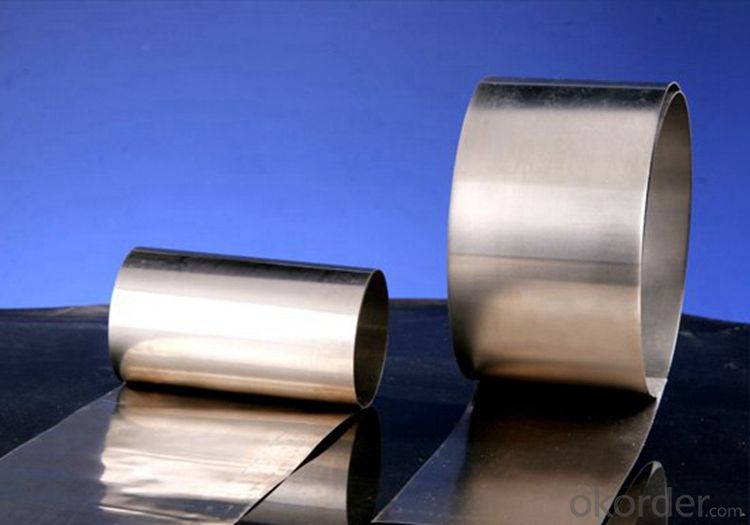

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for heat transfer applications?

- Stainless steel sheets are indeed applicable for heat transfer purposes. Renowned for its superb heat transfer characteristics, stainless steel is widely favored for diverse applications that require heat transfer. Its exceptional thermal conductivity ensures effective heat transfer, guaranteeing even distribution of heat throughout the surface. Furthermore, stainless steel exhibits resistance to corrosion and oxidation when exposed to high temperatures, making it a suitable choice for heat transfer applications in extreme heat or corrosive environments. In conclusion, stainless steel sheets are a dependable and long-lasting option for heat transfer applications.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- If uneven surface oxide thickness of stainless steel plate, the surface of base metal thick smooth places and thin places following different degrees of surface and acid dissolved and oxidized surface oxide skin skin attachment site base metal by the acid erosion degree is different, so the steel plate surface is not uniform. Therefore, when the heat treatment is heated, the oxide scale must be uniformly formed. To achieve this, we must pay attention to the following problems: stainless steel plate in the heating oil if the workpiece surface, oil adhesion of oxide thickness parts and other parts of the oxide thickness and composition is different, and will produce carburizing.

- Q: What's the drill for stainless steel?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: How can I classify stainless steel plates?

- Stainless steel plates are classified according to different standards and have different classifications:1, stainless steel plate according to the thickness classification: can be divided into: sheet (0.2mm-4mm), medium plate (4mm-20mm), thick plate (20mm-60mm), super thick plate (60-115mm).

- Q: What is the thickness range for stainless steel sheets?

- The thickness of stainless steel sheets can differ based on the grade and application at hand. In general, stainless steel sheets come in thicknesses that span from 0.4mm to 6mm. Nonetheless, specific purposes may necessitate the use of thinner or thicker sheets. To ascertain the suitable thickness range for a particular project or application, it is crucial to seek advice from a supplier or consult industry standards.

- Q: What are the different types of stainless steel sheet finishes?

- There are several types of stainless steel sheet finishes, including No. 1, 2B, No. 4, BA, and satin.

- Q: What are the common sizes and thicknesses available for stainless steel sheets?

- Different applications and requirements can be accommodated with stainless steel sheets, which are available in a variety of sizes and thicknesses. Commonly used sizes for these sheets range from 36 inches by 96 inches (3 feet by 8 feet) to 48 inches by 120 inches (4 feet by 10 feet), with some variations in between, making them suitable for construction, industrial, and architectural projects. Regarding thickness, stainless steel sheets can be obtained in different gauges. The most frequently encountered thicknesses include 22 gauge (0.030"), 20 gauge (0.036"), 18 gauge (0.048"), 16 gauge (0.060"), 14 gauge (0.075"), and 12 gauge (0.105"). For more delicate applications, thinner sheets such as 26 gauge (0.018") and 24 gauge (0.024") are also available. It is worth noting that these sizes and thicknesses may vary depending on the manufacturer and supplier. Additionally, specific project requirements can be met by placing custom orders for sizes and thicknesses that are not readily available.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Yes, stainless steel sheets are suitable for decorative purposes. Stainless steel has a sleek and modern appearance that adds a touch of elegance and sophistication to any space. Its smooth and reflective surface creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Additionally, stainless steel is highly durable and resistant to corrosion, making it a long-lasting choice for decorative applications. The versatility of stainless steel sheets allows them to be used in various decorative forms, such as wall panels, backsplashes, countertops, and even furniture. Whether in residential or commercial settings, stainless steel sheets can be utilized to create stunning and eye-catching decorative elements that complement any interior design style.

- Q: What is the fire resistance rating of stainless steel sheets?

- Stainless steel sheets lack an inherent fire resistance rating as they are not naturally fire resistant materials. Nevertheless, stainless steel can demonstrate commendable fire resistance attributes due to its high melting point and low thermal conductivity. Consequently, stainless steel sheets are less prone to melting or transferring heat during a fire, thus impeding the spread of flames. Furthermore, stainless steel possesses corrosion resistance, which further bolsters its performance in fire scenarios. However, it should be emphasized that the fire resistance of a structure or system hinges on a combination of diverse factors, encompassing the comprehensive design, construction, and utilization of fire-resistant materials. Consequently, the fire resistance rating of stainless steel sheets may fluctuate depending on the specific application and the overarching fire protection measures implemented.

- Q: Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel prices higher: in terms of price, 304 is far higher than the price of 201. Because 304 quality is better than 201 stainless steel, and 304 for imported stainless steel plate, 201 for domestic stainless steel plate, so 304 of the price is naturally higher.

Send your message to us

Stainless Steel Coils/Sheets/Plates Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords