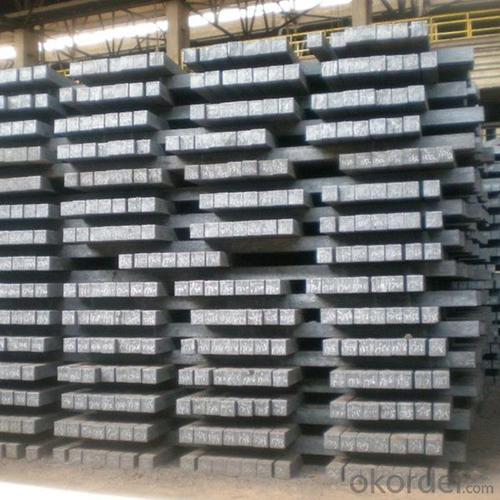

steel billets, square steel bar, mild steel bar China manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel billets, square steel bar, mild steel bar China manufacturer

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195/215/235/345/45#/3SP/5SP,ect

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and

various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like

Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Steel billets, mild steel bar chemical properties

| Ladle Analysis: | ||

| Designation | Carbon | Manganese |

| C15 | 0.12-0.18 | 0.30-0.60 |

| C18 | 0.15-0.21 | 0.30-0.60 |

| C20 | 0.17-0.23 | 0.30-0.60 |

| C15 MMn | 0.12-0.18 | 0.60-1.00 |

| C18 MMn | 0.15-0.21 | 0.60-1.00 |

| C20 MMn | 0.17-0.23 | 0.60-1.00 |

| C15 HMn | 0.12-0.18 | 1.00-1.50 |

| C18 HMn | 0.15-0.21 | 1.00-1.50 |

| C20 HMn | 0.17-0.23 | 1.00-1.50 |

- Q: What are the different methods of steel billet surface honing?

- There are various techniques available for honing the surface of steel billets, each serving a specific purpose and yielding distinct outcomes. Some commonly employed methods are as follows: 1. Manual Honing: This traditional approach entails the use of handheld honing tools, such as stones or abrasive pads, to manually eliminate imperfections or roughness from the steel billet's surface. Skilled operators meticulously rub the honing tool along the billet's surface until the desired level of smoothness is attained. 2. Mechanical Honing: To automate the honing process, mechanical honing machines are employed. These machines are equipped with rotating abrasive stones or pads that traverse the billet's surface, eliminating any irregularities. Mechanical honing allows for a more consistent and precise honing process, with the ability to control factors such as pressure, speed, and contact area. 3. Diamond Honing: Diamond honing is a specialized technique that utilizes tools coated with diamond particles to achieve a high level of precision and smoothness. The diamond particles on the honing tool offer superior cutting capabilities, enabling the removal of even the smallest imperfections. This method is often utilized for honing high-quality steel billets that necessitate a flawless surface finish. 4. Hydrohoning: Also known as abrasive flow machining, hydrohoning involves employing a viscous abrasive medium that is forced through the internal passages of the billet to eliminate surface irregularities. This method is particularly effective for honing complex shapes or hard-to-reach internal surfaces. The abrasive medium can be adjusted to obtain different levels of surface finish. 5. Electrochemical Honing: Electrochemical honing combines the principles of electrochemical machining and honing. It involves utilizing a specialized electrolyte solution and a honing tool with an electrode to remove material from the billet's surface. This method is effective for honing hard materials and achieving a smooth, mirror-like finish. These represent only a selection of the diverse methods available for honing the surface of steel billets. The choice of technique relies on factors such as the desired surface finish, the complexity of the billet's shape, the material being honed, and the level of precision required.

- Q: How are steel billets used in the manufacturing of heavy machinery?

- Steel billets are a crucial component in the manufacturing of heavy machinery. These billets are essentially semi-finished steel products that are hot-rolled or forged into a specific shape, usually a square or rectangle. The first step in using steel billets for heavy machinery is to heat them to a high temperature, making them malleable and easier to work with. Once heated, the billets are then shaped and formed through various processes such as extrusion, rolling, or forging. This allows manufacturers to create the desired components and parts needed for heavy machinery, such as gears, shafts, frames, and structural components. The use of steel billets in heavy machinery manufacturing is essential due to the inherent properties of steel. Steel is known for its high tensile strength, durability, and resistance to wear and tear. These properties make it an ideal material for heavy machinery that is subjected to intense forces, vibrations, and harsh operating conditions. Moreover, steel billets offer versatility in terms of customization and design. Manufacturers can modify the shape, size, and composition of the billets to meet the specific requirements of the heavy machinery being produced. This flexibility allows for the creation of complex and intricate components that can withstand the demands of heavy-duty applications. Once the steel billets are shaped into the desired components, they undergo further processes such as heat treatment, machining, and finishing to enhance their mechanical properties and precision. These steps ensure that the final products meet the required specifications and standards for heavy machinery manufacturing. In summary, steel billets play a crucial role in the manufacturing of heavy machinery. Their malleability, strength, and customization options make them an ideal material for creating durable and reliable components that can withstand the demands of heavy-duty applications.

- Q: How does the carbon content affect the properties of a steel billet?

- The carbon content in a steel billet has a significant impact on its properties. Generally, steel is an alloy made primarily of iron and carbon. The carbon content determines the steel's hardness, strength, and other mechanical properties. Low carbon steel, also known as mild steel, typically contains less than 0.3% carbon. It is relatively soft, malleable, and easy to work with. Low carbon steel is often used for applications that require good formability, such as construction materials, automotive parts, and household appliances. Medium carbon steel contains carbon content ranging from 0.3% to 0.6%. It offers improved strength and hardness compared to low carbon steel. Medium carbon steel is commonly used in applications requiring higher load-bearing capacity, such as gears, shafts, and tools. High carbon steel, with carbon content exceeding 0.6%, is known for its exceptional strength and hardness. It is used in applications that require high resistance to wear, such as cutting tools, springs, and high-strength wires. However, high carbon steel tends to be more brittle and less ductile compared to low and medium carbon steels. In addition to influencing mechanical properties, carbon content affects the steel's ability to be heat treated. Low carbon steel cannot be hardened through heat treatment, while medium and high carbon steels can be heat treated to achieve desired hardness and strength. It is important to note that other alloying elements, such as manganese, chromium, and nickel, can be added to steel to further enhance its properties. However, carbon content remains a critical factor in determining the overall performance of a steel billet.

- Q: How are steel billets used in the manufacturing of medical devices?

- Steel billets are used in the manufacturing of medical devices in various ways. Firstly, steel billets serve as a raw material for the production of surgical instruments, such as scalpels, forceps, and scissors. These devices require a high level of strength, durability, and corrosion resistance, which steel billets can provide. Additionally, steel billets are used in the manufacturing of implants, such as joint replacements and dental implants. These devices need to be able to withstand the load and stress exerted by the human body, and steel billets are an ideal material due to their excellent mechanical properties. Moreover, steel billets are used in the production of medical equipment, such as hospital beds, wheelchairs, and surgical tables. These devices require a sturdy and robust structure, and steel billets can provide the necessary strength and stability. Furthermore, steel billets are also utilized in the manufacturing of medical equipment components, such as brackets, frames, and supports. These components play a crucial role in the functioning and stability of medical devices, and steel billets are often chosen due to their high machinability and weldability. Overall, steel billets are an essential raw material in the manufacturing of various medical devices. Their strength, durability, corrosion resistance, and other mechanical properties make them a suitable choice for producing surgical instruments, implants, medical equipment, and their components.

- Q: What are the different methods of shaping steel billets?

- There are several methods of shaping steel billets, including hot rolling, cold rolling, forging, extrusion, and casting. Each method involves different techniques and processes to shape the steel billets into desired forms and dimensions.

- Q: How do steel billets affect the overall cost of a project?

- Steel billets can have a significant impact on the overall cost of a project. Firstly, the cost of steel billets themselves can vary depending on factors such as the size, grade, and market demand. Higher quality or specialized steel billets may come at a higher cost, while lower quality or readily available billets may be more cost-effective. Additionally, the quantity of steel billets required for a project can greatly affect the overall cost. Larger projects that require a substantial amount of steel may have to purchase a greater number of billets, which can increase the cost. On the other hand, smaller projects with fewer steel requirements may be able to minimize costs by purchasing a smaller quantity of billets. Transportation and logistics also play a role in the cost of steel billets. The distance between the billet supplier and the project site, as well as the availability of transportation options, can impact the overall cost. Shipping costs, handling fees, and other associated expenses can add to the final cost of the project. Furthermore, the quality and suitability of the steel billets for the specific project requirements can influence costs. Using low-quality or unsuitable billets may result in delays, rework, or even failure of the project, leading to additional expenses. Therefore, it is crucial to ensure that the chosen steel billets meet the necessary specifications and standards, even if they come at a higher initial cost. Lastly, the overall market conditions and fluctuations in the steel industry can affect the cost of steel billets. Factors such as supply and demand, currency exchange rates, and global economic trends can impact the price of steel billets, thereby influencing the overall project cost. In summary, the cost of steel billets can have a significant impact on the overall cost of a project. Factors such as the cost of the billets themselves, the quantity required, transportation and logistics, quality and suitability, and market conditions all contribute to the final cost. Therefore, careful consideration and analysis of these factors are essential to effectively manage and budget for steel billets in a project.

- Q: How are steel billets used in the production of turbine blades?

- Turbine blades rely heavily on steel billets, which serve as a fundamental building block in their production. These billets, essentially semi-finished steel products, serve as the initial material for the manufacturing process. To commence, the selection of steel billets is a meticulous process, taking into account specific requirements such as composition, strength, and durability. Once chosen, the billets undergo a series of processing steps to transform them into turbine blades. The initial step involves subjecting the steel billets to high temperatures in a furnace, a process known as forging. This procedure enhances the malleability of the steel, making it easier to work with. Once heated, the billets are then shaped into turbine blades through the application of mechanical forces. Following the initial forging process, the turbine blades are refined through a range of machining operations. These operations encompass precision cutting, grinding, and drilling, all aimed at achieving the desired dimensions, surface finish, and aerodynamic profiles. Aside from shaping and refinement, steel billets also play a pivotal role in strengthening and ensuring the integrity of turbine blades. Through heat treatment processes like quenching and tempering, the billets are hardened and tempered, resulting in desired mechanical properties such as high strength and resistance to fatigue. Moreover, steel billets provide the necessary material properties to withstand the harsh operating conditions of turbines. They exhibit excellent corrosion resistance, a crucial attribute for blades operating in environments with high temperatures, pressure, and moisture. In summary, steel billets are indispensable in turbine blade production as they serve as the starting material, facilitate shaping and refinement, and offer the required strength and durability for these critical components in power generation.

- Q: What is the difference between a steel billet and a steel bar?

- The manufacturing industry utilizes both steel billets and steel bars as raw materials, although there are notable distinctions between the two. 1. Shape and Size: Steel billets are typically semi-finished products with rectangular or square shapes and larger cross-sections compared to steel bars. They are produced through continuous casting or hot rolling, resulting in a rough and uneven surface. Conversely, steel bars are long and cylindrical, often obtained by further processing the steel billet through methods like hot rolling, cold drawing, or machining. Steel bars have a smoother and more polished surface. 2. Manufacturing Process: Steel billets are usually produced directly from molten steel through continuous casting or solidifying the liquid steel in molds. This creates a solid steel block that is later shaped into various forms. On the other hand, steel bars are derived from steel billets through additional manufacturing processes, such as hot rolling. This involves passing the billet through rolling mills to reduce its size and shape it into a bar. 3. Uses and Applications: Steel billets primarily serve as raw materials for further processing, including forging, extrusion, or rolling, to manufacture end products like bars, rods, wire, pipes, or structural components. In contrast, steel bars are extensively utilized in construction, manufacturing, and engineering industries for applications that necessitate strength, durability, and a consistent shape. They are employed as reinforcement in concrete structures, as shafts or axles in machinery, or as components in the automotive industry. In conclusion, steel billets are intermediate products obtained through casting or hot rolling, while steel bars are finished products obtained through additional processing of the billet. Billets possess larger cross-sections and rougher surfaces, while bars are cylindrical with smoother exteriors. Both billets and bars have distinctive roles in the manufacturing industry, with billets serving as raw materials for diverse products and bars being employed in various applications that demand strength and durability.

- Q: How are steel billets inspected for quality?

- Steel billets are typically inspected for quality using various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and dye penetrant testing. These tests help identify any surface defects, cracks, or internal flaws in the billets, ensuring that they meet the required quality standards before further processing.

- Q: What are the different surface treatments for rust prevention in steel billets?

- There are several surface treatments available for rust prevention in steel billets. These treatments aim to protect the steel surface from corrosion caused by exposure to moisture or other corrosive elements. Some of the commonly used surface treatments include: 1. Hot-dip galvanizing: This process involves immersing the steel billets in a bath of molten zinc, which creates a protective layer on the surface. The zinc coating acts as a barrier against corrosion, preventing the steel from coming into contact with corrosive elements. 2. Electroplating: In this method, a thin layer of a corrosion-resistant metal, such as zinc, nickel, or chromium, is deposited onto the steel billet surface using an electric current. The electroplated layer provides a protective barrier against rust formation. 3. Paint coatings: Applying a layer of paint on the steel billet surface can effectively prevent rust. The paint forms a protective barrier, preventing moisture or corrosive substances from reaching the steel surface. Multiple layers of paint, including primer and topcoat, are typically applied to enhance durability. 4. Powder coating: This process involves applying a dry powder, usually made of epoxy, polyester, or acrylic, to the steel billet surface. The powder is electrostatically charged and adheres to the metal, forming a protective coating when heated. Powder coating provides excellent corrosion resistance and durability. 5. Phosphating: Phosphating is a chemical treatment method that involves applying a phosphate coating to the steel surface. The phosphate layer enhances the steel's resistance to corrosion and provides a good base for subsequent paint or powder coating. 6. VCI (Vapor Corrosion Inhibitor) packaging: This method utilizes special packaging materials that release volatile corrosion inhibitors. These inhibitors create a protective atmosphere around the steel billets, preventing rust formation during storage or transportation. It is important to note that the choice of surface treatment depends on factors such as the steel's intended application, environment, and cost considerations. Each treatment method has its advantages and limitations, and it is essential to select the most appropriate treatment for effective rust prevention in steel billets.

Send your message to us

steel billets, square steel bar, mild steel bar China manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords