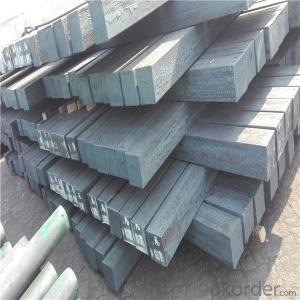

Square Steel Bar, Steel Billets Exporter (60X60-150X150),Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product name: Steel billet

1)Application

---Metallurgy

2) Specification (see below)

---Standard: GB/JIS/ASTM

---Size: 80*80mm-150*150mm

---Length: 6-12mtrs or Customised

---Steel material: Q235,Q275,Q345,3SP,5SP,20MnSi

--- Technique: Hot rolled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Photos:

Company Main Product Introduction

·Steel Profile:H-Beam/I-Beam/Equal Angle/Unequal Angle/U Channel /Flat Bar

·Steel Plate:Hot Rolled Coil/Hot Rolled Checkered Coil/Cold Rolled Coil/Cutting Sheet

·Wire Bar: Round Bar /Wire Rod/Deformed Bar

·Steel Pipes: Seamless Pipe, Square/Round Pipes

·Galvanized Steel: Angle/Channel/I-Beam/Round Bar/Flat Bar/Round-Square Pipe

FAQ:

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: What are the different types of steel staircases and handrails?

- There are several types of steel staircases and handrails available, including straight staircases, spiral staircases, and floating staircases. Handrails can be simple and straight, or they can feature decorative elements such as scrolls or twists. Additionally, there are options for different finishes and materials, such as brushed steel or powder-coated finishes.

- Q: How do steel products contribute to the infrastructure development of cities and urban areas?

- Steel products contribute to the infrastructure development of cities and urban areas in several ways. Firstly, steel is a versatile and durable material that is used in the construction of buildings, bridges, and roads, providing the necessary strength and stability to withstand heavy loads and harsh weather conditions. Secondly, steel is a key component in the construction of high-rise buildings, allowing for taller and more efficient use of limited urban space. Additionally, steel products such as pipes and beams are crucial in the development of water supply and transportation systems, ensuring the efficient flow of resources and people within cities. Overall, the use of steel products in infrastructure development enhances the safety, efficiency, and sustainability of cities and urban areas.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each designed for specific applications. Some common types include compression springs, which are used to resist compressive forces and store energy; extension springs, which resist stretching and are commonly found in trampolines or garage doors; torsion springs, which generate rotational force and are used in clothespins or mousetraps; and flat springs, which provide flexibility in limited spaces, such as in automotive suspensions. Each type of spring has a unique design and purpose, allowing them to be utilized in a wide range of industries and products.

- Q: How is steel mesh used in construction?

- Steel mesh is commonly used in construction as a reinforcement material. It is mainly used to strengthen concrete structures such as floors, walls, and foundations. The mesh is placed within the concrete to provide additional tensile strength, preventing cracks and enhancing the overall durability of the structure. Additionally, steel mesh is used in the construction of fences, barriers, and cages to provide security and containment.

- Q: What are the different types of steel scaffolding and support systems available?

- There are several different types of steel scaffolding and support systems available, including tube and clamp scaffolding, system scaffolding (such as cuplock and ringlock scaffolding), frame scaffolding, and shoring systems. Each type has its own unique features and advantages, allowing for various applications and requirements in construction and maintenance projects.

- Q: How is steel pipe coated for corrosion resistance?

- Steel pipe can be coated for corrosion resistance through various methods such as galvanization, epoxy coating, or fusion-bonded epoxy coating. Galvanization involves applying a layer of zinc to the steel surface, forming a protective barrier against corrosion. Epoxy coating involves applying a layer of epoxy resin to the pipe surface, providing a durable barrier against corrosion. Fusion-bonded epoxy coating involves applying a powder coating to the heated pipe surface, which then melts and fuses to form a corrosion-resistant layer. These coating methods help protect steel pipes from the damaging effects of corrosion, extending their lifespan and maintaining their structural integrity.

- Q: What are the different types of steel products used in the manufacturing of kitchen appliances?

- The different types of steel products commonly used in the manufacturing of kitchen appliances include stainless steel, carbon steel, and galvanized steel. Stainless steel is a popular choice due to its resistance to corrosion and its sleek appearance. Carbon steel is often used for cookware due to its heat conductivity and durability. Galvanized steel may be used for the exterior of appliances to provide a protective coating and prevent rusting.

- Q: How are steel products used in the food processing industry?

- Steel products are used extensively in the food processing industry due to their durability, corrosion resistance, and ease of cleaning. They are used to manufacture various equipment and machinery, such as storage tanks, conveyors, cutting and slicing tools, and food processing lines. Steel products ensure food safety by preventing contamination and maintaining hygiene standards, making them indispensable in the food processing industry.

- Q: What are the different types of steel meshes and their applications?

- There are several different types of steel meshes with various applications. Some common types include welded wire mesh, expanded metal mesh, and woven wire mesh. Welded wire mesh is frequently used in construction, agriculture, and fencing due to its strength and durability. Expanded metal mesh is often utilized for grating, walkways, and filters due to its high load-bearing capacity and ventilation properties. Woven wire mesh is commonly used in industries such as mining, filtration, and security due to its versatility and ability to withstand heavy-duty applications. Overall, steel meshes serve diverse purposes and are chosen based on their specific properties and intended applications.

- Q: How do steel products contribute to the construction of sports facilities and stadiums?

- Steel products are essential in the construction of sports facilities and stadiums due to their strength, durability, and versatility. From the framework to the roofing, steel is used to create the structural support required for large-scale constructions. It helps ensure the safety and stability of the facilities, allowing them to withstand heavy loads, extreme weather conditions, and intense activities. Additionally, steel products can be customized to meet specific design requirements, enabling architects and engineers to create unique and visually appealing sports venues.

Send your message to us

Square Steel Bar, Steel Billets Exporter (60X60-150X150),Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords