Carbon Square Billets Q275/3SP in China for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

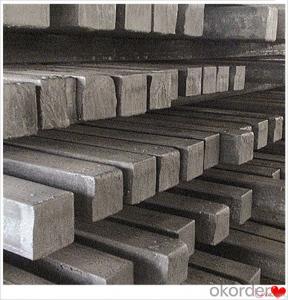

Description of Carbon Square Billets Q275/3SP in China for Construction

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

Festures of Carbon Square Billets Q275/3SP in China for Construction

Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products. Billets are used fro rolling of CRS TMT Re-Bars..

Product Size of Carbon Square Billets Q275/3SP in China for Construction

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Carbon Square Billets Q275/3SP in China for Construction

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Carbon Square Billets Q275/3SP in China for Construction

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Carbon Square Billets Q275/3SP in China for Construction

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas. These billets, which are essentially semi-finished steel products, serve as the raw material for various structural components used in the construction process. One of the primary applications of steel billets in stadium and arena construction is for the fabrication of steel beams and columns. These structural elements provide the necessary support and stability to the overall structure. Steel billets are first heated and then passed through rolling mills to acquire the desired shape and size required for these beams and columns. Moreover, steel billets are also used in the production of steel reinforcing bars, commonly known as rebars. These rebars are used to reinforce the concrete structures within stadiums and arenas, such as foundations, walls, and floors. The combination of steel and concrete enhances the structural integrity and load-bearing capacity of these structures, making them capable of withstanding heavy loads, vibrations, and external forces. Additionally, steel billets are utilized in the construction of roof trusses and frames, which provide support for the stadium or arena's roofing system. These steel components offer the necessary strength and durability to withstand the weight of the roof, while also ensuring the overall stability of the structure. Furthermore, steel billets are employed in the production of seating structures, staircases, handrails, and other architectural elements within stadiums and arenas. These components not only contribute to the overall aesthetics of the venue but also provide safety and comfort to spectators. In summary, steel billets are indispensable in the construction of stadiums and arenas. They are transformed into various structural and architectural components that provide strength, stability, and durability to the overall structure. By utilizing steel billets, stadiums and arenas can be built to withstand the demands of large crowds, harsh weather conditions, and the test of time.

- Q: How is the surface condition of steel billets checked?

- The surface condition of steel billets is typically checked through visual inspection and various non-destructive testing methods. Visual inspection involves thoroughly examining the surface of the billets for any visible defects such as cracks, pits, dents, or scratches. This is usually done by trained inspectors who have a keen eye for detecting surface imperfections. In addition to visual inspection, various non-destructive testing techniques are employed to assess the surface condition of steel billets. These techniques include magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing. Magnetic particle testing involves applying a magnetic field to the billet's surface and then applying fine iron particles. If there are any surface defects, such as cracks or inclusions, the magnetic particles will be attracted to these areas and form visible indications. Liquid penetrant testing involves applying a liquid dye to the surface of the billet. The dye penetrates any surface defects, and after a certain period of time, excess dye is removed, and a developer is applied. The developer draws out the dye from any surface defects, making them visible and easy to detect. Ultrasonic testing utilizes high-frequency sound waves to detect surface and subsurface defects. A transducer is used to generate sound waves that penetrate the billet's surface. If there are any defects, such as cracks or voids, the sound waves will reflect back, and by analyzing the reflected waves, any surface or subsurface flaws can be identified. Eddy current testing involves passing an alternating current through a coil placed near the billet's surface. Any surface defects or variations in the material's conductivity will cause changes in the current flow, which can be detected and analyzed to determine the surface condition. These non-destructive testing methods provide accurate and reliable information about the surface condition of steel billets, helping to ensure their quality and integrity before further processing or usage.

- Q: How are steel billets marked for identification and traceability?

- Various methods are utilized to mark steel billets for identification and traceability. One prevalent approach involves the utilization of unique identification numbers or codes. These numbers or codes can be engraved or stamped onto the billet's surface, enabling easy identification. Laser engraving machines or steel stamping tools are frequently employed for this purpose. Aside from identification numbers, other significant details, such as the grade, heat number, and production date, can also be marked on the billet. These details play a crucial role in traceability, allowing for the tracking of the steel's origin and quality. Moreover, some manufacturers may choose to employ additional marking techniques, such as paint or ink marking. This may entail the use of specific colors or symbols to represent different characteristics or attributes of the billet. For example, a particular color might indicate the intended use of the steel, while a symbol may signify the manufacturer's logo or quality certification. Overall, the marking of steel billets for identification and traceability is indispensable in ensuring quality control, verifying compliance with industry standards, and facilitating efficient inventory management throughout the supply chain.

- Q: What are the potential applications of steel billets in the medical sector?

- The medical sector has a wide range of potential applications for steel billets. One key use is in the manufacturing of medical instruments and surgical tools. Steel's high strength and durability make it an ideal material for producing precise and reliable instruments. Scalpels, forceps, bone saws, and orthopedic implants are just a few examples of the various medical tools that can be made from steel billets and are essential for surgeries and procedures. Moreover, steel billets can be utilized in the production of medical equipment like hospital beds, wheelchairs, and stretchers. These products require a strong and robust material to ensure patient safety and comfort. Steel provides the necessary strength to support the weight of patients and withstand regular usage, making it an excellent choice for these applications. Additionally, steel billets can be used in the construction of medical facilities and infrastructure. Steel is renowned for its structural integrity, making it suitable for building hospitals, clinics, and research laboratories. Steel structures offer resistance against earthquakes, fires, and other natural disasters, ensuring the safety of both medical personnel and patients. Furthermore, steel billets can be employed in the manufacturing of medical storage systems and cabinets. These storage solutions are crucial for maintaining a sterile and organized environment, preventing cross-contamination, and ensuring the proper storage of medical supplies and equipment. To sum up, steel billets have extensive potential in the medical sector. Steel's strength, durability, and reliability make it an invaluable material for enhancing patient care and safety, whether it's through the production of surgical instruments, medical equipment, construction of medical facilities, or manufacturing of medical storage solutions.

- Q: What are the applications of steel billets?

- Steel billets are primarily used as raw material in the production of various steel products such as bars, rods, wire, and seamless tubes. They are also used in the manufacturing of components for automotive, construction, and machinery industries. Additionally, steel billets can be further processed to produce forgings, which are used in heavy machinery and equipment.

- Q: What are the different methods of steel billet surface treatment?

- There are several methods of steel billet surface treatment, including pickling, shot blasting, grinding, and coating. Pickling involves immersing the billet in an acid solution to remove impurities and create a clean surface. Shot blasting uses high-speed particles to remove rust and mill scale from the surface. Grinding is a mechanical process that smoothens the surface through abrasion. Coating is another method where a protective layer is applied to prevent corrosion and enhance the appearance of the billet.

- Q: How are steel billets marked for identification?

- Various techniques and methods are utilized to mark steel billets for identification. One common approach involves the use of marking stamps or dies, which contain specific alphanumeric characters or symbols that are pressed onto the billet's surface. This results in a permanent and visible mark that can be easily read and identified. Another method involves applying paint or ink to the surface of the billet, creating a distinct color or pattern. This mark can be visually inspected and compared to the corresponding identification code. In addition to manual methods, some steel billets are marked using laser engraving or etching. This precise technique utilizes a laser beam to remove a thin layer of material from the billet's surface, leaving a permanent identification mark. Laser marking is highly accurate and can produce detailed marks, including barcodes or QR codes that can be easily scanned for identification purposes. Furthermore, identification marks may be applied during the manufacturing process. These marks can include information such as steel grade, batch number, manufacturer's logo, or other relevant details. Hot stamping, embossing, or engraving techniques are commonly employed to ensure durability and visibility of these marks. Overall, a combination of manual techniques, such as marking stamps or paint marking, along with advanced methods like laser engraving or etching, are used to mark steel billets for identification. These identification marks play a vital role in traceability, quality control, and ensuring proper handling and usage of steel billets in various industrial applications.

- Q: What are the common grades of steel used for billets?

- The common grades of steel used for billets vary depending on the intended application and specific requirements. However, some of the most commonly used grades include: 1. Carbon Steel: Carbon steel billets are widely used due to their high strength, durability, and affordability. Grades such as AISI 1018, 1020, 1045, and 1060 are commonly used for general-purpose applications. 2. Alloy Steel: Alloy steel billets are blended with specific alloying elements to enhance their mechanical properties such as strength, toughness, and corrosion resistance. Grades like AISI 4140, 4340, and 8620 are commonly used for applications requiring higher strength, heat resistance, or wear resistance. 3. Stainless Steel: Stainless steel billets are chosen for their excellent corrosion resistance and aesthetic appeal. Grades such as 304, 316, and 420 are commonly used for various applications, including construction, automotive, and food processing industries. 4. Tool Steel: Tool steel billets are specifically designed to have high hardness, wear resistance, and toughness. Grades such as AISI O1, D2, and A2 are commonly used for manufacturing cutting tools, dies, and molds. It is important to note that the selection of the appropriate grade of steel depends on the specific requirements of the application, such as mechanical properties, corrosion resistance, and temperature resistance. Consulting with a metallurgist or an expert in the field can help determine the most suitable grade of steel for billet production.

- Q: What is the role of steel billets in the construction of railway stations?

- Steel billets are essential in constructing railway stations, serving as semi-finished steel products that are typically rectangular or square in shape. They function as raw materials for various construction purposes. Within the realm of railway stations, steel billets are primarily utilized to fabricate structural components like beams, columns, and trusses. These components provide the necessary strength and stability to support the weight of the station building, platforms, and any associated structures. A key advantage of employing steel billets in railway station construction lies in their high strength-to-weight ratio. Steel is widely recognized for its exceptional strength, making it an ideal material for supporting heavy loads. By incorporating steel billets, engineers can design and construct railway stations capable of enduring the constant traffic and heavy footfall characteristic of these public spaces. Furthermore, steel billets offer exceptional durability, corrosion resistance, and fire resistance, all of which are vital factors in ensuring the long-term safety and structural integrity of railway stations. These properties establish steel billets as a reliable and cost-effective choice for construction projects prioritizing safety and longevity. Moreover, steel billets can be easily shaped and fabricated into various sizes and dimensions, allowing for flexibility in design and construction. This versatility enables architects and engineers to create aesthetically appealing and functional railway station structures tailored to the specific project requirements. In summary, steel billets play a crucial role in railway station construction by providing the necessary strength, durability, and versatility required for the structural components supporting these vital transportation hubs. By utilizing steel billets, railway station construction projects can be completed efficiently, guaranteeing the safety and comfort of passengers for years to come.

- Q: How do steel billets contribute to the overall strength of a structure?

- Steel billets play a crucial role in contributing to the overall strength of a structure. These billets, which are essentially semi-finished forms of steel, are used as raw material in the production of various structural components. One of the primary reasons steel billets enhance the strength of a structure is due to the inherent properties of steel itself. Steel is known for its exceptional strength and durability, making it an ideal material for construction purposes. When steel billets are used in the manufacturing process, they provide a solid foundation for creating stronger structural elements. Steel billets are typically hot-rolled or forged to shape different structural components, such as beams, columns, and plates. During the manufacturing process, the steel is subjected to high temperatures and pressure, resulting in a refined grain structure. This refined grain structure enhances the strength and toughness of the steel, making it more resistant to deformation and structural failure. Moreover, steel billets can be further processed to achieve specific mechanical properties that are required for different structural applications. For example, the billets can undergo heat treatment processes such as quenching and tempering, which improve their hardness and toughness. This allows the steel to withstand higher loads and stresses, thereby contributing to the overall strength and stability of the structure. In addition to their inherent strength, steel billets also offer advantages in terms of versatility and design flexibility. They can be easily shaped into various sizes and dimensions, allowing engineers to create complex structural configurations. This versatility enables the optimization of the structural design, ensuring that the load-bearing capacity and overall strength of the structure are maximized. Furthermore, steel billets have excellent weldability, allowing them to be seamlessly joined with other steel components. This ensures the integrity and continuity of the structure, preventing weak points or potential failure zones. By creating a unified and interconnected system, the steel billets contribute to the overall strength and stability of the structure. In conclusion, steel billets make a significant contribution to the overall strength of a structure through their inherent strength, refined grain structure, and ability to undergo various heat treatment processes. They provide a solid foundation for manufacturing structural components, allowing them to withstand high loads and stresses. The versatility and design flexibility of steel billets further optimize the structural design, while their excellent weldability ensures the integrity of the structure. Consequently, steel billets are essential in creating robust and durable structures that can withstand the test of time.

Send your message to us

Carbon Square Billets Q275/3SP in China for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords