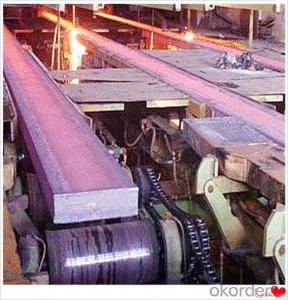

Carbon Steel Billets Square Billets 5sp 3sp& Q235

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Tianjin, China (Mainland) | Brand Name: | cnbm | Grade: | 3SP,5SP,Q235,20MnSi. |

| Shape: | Square | Length: | 5.8-12m or as per request | Standard: | GB |

| Technique: | Hot Rolled | Dimensions: | 100*100-150*150mm | Alloy Or Not: | Non-alloy |

| Secondary Or Not: | Non-secondary | place of origin: | Tianjin | MOQ: | 1O tons at least one container |

| trade term: | FOB, CIF, CFR | packing: | in bundles,seaworthy packing | delivery date: | 15-20 days after receiving the down payment or LC. |

| payment term: | Down payment 30% T/T and balance 70% T/T or L/C. | Carbon Steel Billets with Max Carbon: | 0.30% |

Packaging & Delivery

| Packaging Details: | in bundles |

| Delivery Detail: | within 25 days after we received your advanced payment |

| PRODUCT NAME | Carbon Steel Billets Square Billets |

| material | 3SP,5SP,Q235,20MnSi. |

| size | 100*100MM

120*120MM

130*130MM

150*150MM

|

| length | 6M,9M,12M or as per request |

| capability | 20000MT PER MONTH |

| technique | hot rolled |

| certification | GB |

| delivery time | within 25 days after we received your advanced payment |

| packing | in bundles |

Thanks for your interest on our product carbon square steel billets. If you have any special requirments , please feel free to contanct us.

We would reply you in the first time.

Best regards.

- Q: What are the safety measures involved in handling steel billets?

- When handling steel billets, there are several important safety measures that should be followed to ensure the well-being of workers and prevent accidents. 1. Personal Protective Equipment (PPE): It is essential for workers to wear appropriate PPE, such as safety goggles, gloves, steel-toed boots, and helmets, to protect themselves from potential hazards. This equipment provides protection against sharp edges, flying debris, and falling objects. 2. Training: Proper training is crucial for workers involved in handling steel billets. They should be trained in safe lifting techniques, handling procedures, and the use of equipment like cranes or forklifts. This knowledge will help minimize the risk of musculoskeletal injuries and accidents caused by improper handling. 3. Equipment Inspection: Regular inspection of equipment, such as cranes, hoists, and lifting slings, is crucial to ensure their proper functioning. Any defects or malfunctions should be reported and repaired promptly to prevent accidents. 4. Secure Storage: Steel billets should be stored in a secure and organized manner to prevent them from falling or tipping over. Proper racking systems and storage areas should be used to ensure stability and prevent accidents due to falling objects. 5. Adequate Lighting: Good lighting is essential in the working area to ensure clear visibility and prevent accidents caused by tripping or colliding with objects. 6. Floor Conditions: The floor should be kept clean and free from hazards, such as oil spills or debris, that could cause slips, trips, or falls. Regular cleaning and maintenance are necessary to ensure a safe working environment. 7. Communication: Clear communication among workers involved in handling steel billets is crucial to prevent accidents. Signals, hand gestures, and use of radios or other communication devices can help coordinate movements and prevent collisions or accidents. 8. Emergency Preparedness: Adequate emergency preparedness measures should be in place, including fire extinguishers, first aid kits, and evacuation plans. Workers should be trained in emergency procedures to ensure a swift and safe response in case of an incident. By following these safety measures, risks associated with handling steel billets can be minimized, ensuring a safer work environment for all involved.

- Q: How are steel billets used in the production of agricultural vehicles?

- Steel billets are used in the production of agricultural vehicles as they serve as the raw material for various components and parts. These billets are heated and then formed into desired shapes using processes like forging or casting. They are used to manufacture key structural components such as chassis, axles, and frames, providing the necessary strength and durability for heavy-duty applications in agricultural vehicles.

- Q: What is the typical tensile strength of a steel billet?

- The tensile strength of a steel billet can vary depending on its specific grade and composition. Typically, steel billets have a tensile strength ranging from 370 to 550 megapascals (MPa). This range is commonly observed in low to medium carbon steels, which are utilized in various industries like construction, automotive, and manufacturing. It should be noted that higher-grade steels, including alloy steels, can exhibit considerably higher tensile strengths, surpassing 1000 MPa. Ultimately, the intended application and project requirements dictate the tensile strength of a steel billet.

- Q: How do steel billets contribute to the strength of a structure?

- There are multiple ways in which steel billets contribute to the strength of a structure. To begin with, steel billets are created through the casting process, where molten steel is poured into molds and allowed to solidify. This casting method ensures that the steel billets have a consistent and uniform composition, with minimal impurities. As a result, the final product's structural integrity and strength are enhanced. In addition, steel billets undergo hot rolling or cold rolling, which further enhances their strength. Hot rolling involves heating the steel billets to high temperatures and passing them through a series of rollers to compress and shape the steel into the desired form. This process aligns the steel's grain structure, making it stronger and more resistant to deformation. Furthermore, steel billets are commonly used as raw material for manufacturing other steel products like beams, columns, and plates. These fabricated steel components are then incorporated into structures, providing additional strength and support. The high strength and durability of steel billets make them ideal for withstanding heavy loads, seismic forces, and other external pressures. In addition, steel billets can be alloyed with other elements like carbon, manganese, and chromium to enhance their mechanical properties and increase their strength. The inclusion of these alloying elements improves the steel's hardness, toughness, and resistance to corrosion, making it even more suitable for structural applications. Overall, the role of steel billets in enhancing the strength of a structure is crucial. Through their uniform composition, hot or cold rolling processes, and alloying capabilities, steel billets contribute to the overall structural integrity, durability, and load-bearing capacity of buildings, bridges, and other infrastructure projects.

- Q: How are steel billets cast into shape?

- The process of continuous casting is used to shape steel billets. In this process, molten steel is poured into a copper mold that is cooled by water. The mold is in the shape of a billet, and as the steel is poured, it starts to solidify along the mold's walls. To ensure complete solidification, a water spray is employed at the bottom of the mold, rapidly cooling the steel. As the steel solidifies, it is continuously pulled out of the mold either by a set of rollers or a chain conveyor. Once the billet has solidified entirely, it is cut into desired lengths using a high-speed torch or saw. These cut billets are then transported to the next stage of the steel manufacturing process, such as rolling or forging, where they are further shaped into the final product. Continuous casting enables the production of steel billets with consistent cross-sectional shapes and sizes. This efficient process generates high-quality steel products while minimizing waste.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- This week, although steel prices also rose a few days, but since entering November, the price rose a week, a week plummeted, then rebounded sharply, the roller coaster trend, make steel practitioners the feeling of being alone.

- Q: How are steel billets used in the manufacturing of structural components?

- The manufacturing of structural components heavily relies on steel billets, which are an essential raw material. These billets, usually square or round in shape, are produced through continuous casting, a process that solidifies molten steel into a semi-finished product. After the formation of steel billets, they undergo further processing using different techniques like hot rolling, forging, or extrusion. Hot rolling includes heating the billets and passing them through a sequence of rollers to shape them into desired profiles, such as beams, channels, or angles. This method is crucial for achieving the necessary dimensions, strength, and surface finish. Forging is another technique employed with steel billets, involving heating the billets and shaping them using compressive forces. It is primarily used for manufacturing components that require enhanced strength and durability, like crankshafts, connecting rods, or turbine blades. Extrusion, on the other hand, is a specialized process that utilizes heated billets to create complex shapes by forcing them through a die. This technique is commonly utilized in the production of tubular components, such as pipes, tubes, or hollow sections. These components are extensively used in the construction of structures like bridges, buildings, or infrastructure. Steel billets play a critical role in the manufacturing of structural components by providing the necessary raw material that can be shaped using various fabrication techniques. Their adaptability and versatility make them an indispensable component in the construction industry, ensuring that buildings and structures possess the required strength and durability to withstand different loads and environmental conditions.

- Q: How are steel billets used in the production of industrial furnaces?

- Steel billets serve as a vital element in the manufacturing of industrial furnaces, being a key component required for the production of different furnace parts. To start off, the furnace shell or casing, which is responsible for providing structural integrity and containment, is fabricated using steel billets. These billets are shaped and welded together, forming a robust outer shell capable of enduring the high temperatures and harsh conditions inside the furnace. Additionally, steel billets are utilized in the creation of furnace doors and access panels. These components need to possess strength and resistance to deformation caused by the intense heat generated within the furnace. By employing steel billets, manufacturers can ensure that the doors and access panels are easily operable while maintaining their structural integrity over time. Furthermore, steel billets are also employed in the construction of furnace grates and supports. These components play a crucial role in holding and supporting the materials undergoing heating inside the furnace. By utilizing steel billets, manufacturers are able to fabricate sturdy and heat-resistant supports capable of withstanding heavy loads and high temperatures for extended periods. Moreover, steel billets are frequently employed in the fabrication of heat exchangers within industrial furnaces. Heat exchangers are vital for transferring heat from the combustion chamber to the materials being processed. The use of steel billets ensures that the heat exchangers possess exceptional thermal conductivity and can endure the corrosive effects of the furnace environment. Overall, steel billets have a critical function in the production of industrial furnaces, providing the necessary strength, durability, and resistance to heat required for the various components. Without steel billets, the manufacturing of furnaces capable of withstanding the extreme conditions encountered in industrial processes would be quite challenging.

- Q: How do steel billets contribute to the manufacturing of telecommunications devices?

- Steel billets play a significant role in the manufacturing of telecommunications devices in several ways. Firstly, steel billets serve as a raw material for the production of various components used in telecommunications devices. These components include structural frames, housing, brackets, and mounts, among others. The strength and durability of steel make it an ideal choice for these parts, as they need to withstand harsh environments and provide stability to the devices. Furthermore, steel billets are often used in the production of transmission towers and antenna masts, which are essential for the efficient transmission and reception of signals in the telecommunications industry. These towers and masts need to be sturdy and capable of supporting heavy equipment to ensure uninterrupted communication. Steel, with its high strength and load-bearing capacity, is an ideal material for such applications. Moreover, steel billets are also used in the manufacturing of cable trays and conduits that are essential for organizing and protecting the various cables used in telecommunications devices. These cable management systems ensure that the cables are properly routed and protected from external factors such as moisture, heat, and physical damage. Steel's resistance to corrosion and its ability to withstand extreme conditions make it an excellent choice for these purposes. In addition to its physical properties, steel billets contribute to the manufacturing of telecommunications devices due to their cost-effectiveness. Steel is widely available and relatively inexpensive compared to other materials, making it a preferred choice for manufacturers. Its versatility and ease of fabrication also contribute to the efficient production of telecommunications devices. Overall, steel billets play a crucial role in the manufacturing of telecommunications devices by providing raw materials for various components, supporting infrastructure, and ensuring efficient cable management. Their strength, durability, cost-effectiveness, and availability make them an indispensable material in the telecommunications industry.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets contribute to the overall safety of a structure by providing a strong and durable material for construction. The high strength and toughness of steel billets make them resistant to external forces such as earthquakes, wind, and heavy loads. Additionally, steel billets have excellent fire resistance, as they do not burn or release toxic gases when exposed to high temperatures. This ensures the structural integrity of the building during a fire. Moreover, steel billets can be easily fabricated into various shapes and sizes, allowing for precise engineering and construction, which further enhances the safety and stability of the structure.

Send your message to us

Carbon Steel Billets Square Billets 5sp 3sp& Q235

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords