Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

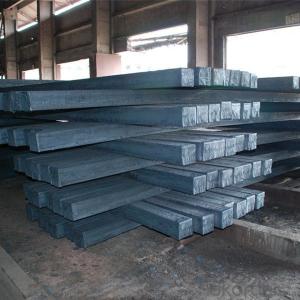

Product Picture

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 1000mt.

Q: What's the delivery time?

A: It will take about 40 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: What are the challenges and innovations in the steel product manufacturing industry?

- The steel product manufacturing industry faces several challenges, including fluctuating raw material costs, intense global competition, and increased environmental regulations. These challenges have led to the need for innovative solutions in order to remain competitive and sustainable. Some of the key innovations in the industry include the adoption of advanced technologies like automation and robotics, the development of high-performance alloys and coatings, and the implementation of energy-efficient processes. Additionally, the industry is exploring new business models, such as circular economy principles, to minimize waste and maximize resource utilization. Overall, the challenges in the steel product manufacturing industry have spurred the industry to embrace innovative practices that enhance productivity, reduce costs, and mitigate environmental impacts.

- Q: How is steel different from iron?

- Steel is different from iron in terms of its composition and properties. While iron is a pure element, steel is an alloy, meaning it is a combination of iron and other elements such as carbon. This alloying process gives steel improved strength, durability, and resistance to corrosion compared to iron. Additionally, steel can be manipulated to have different properties by varying the amounts of alloying elements.

- Q: What are the benefits of using steel in construction?

- There are several benefits to using steel in construction. Firstly, steel is incredibly strong and durable, making it an ideal material for structural support. It can withstand high winds, earthquakes, and other extreme weather conditions, ensuring the safety and longevity of the building. Additionally, steel is a versatile material that can be easily molded and shaped into various designs, allowing for creative and unique architectural structures. Furthermore, steel is fire-resistant, reducing the risk of structural damage and increasing the safety of occupants. Lastly, steel is a sustainable choice as it is 100% recyclable, reducing waste and minimizing the environmental impact of construction projects.

- Q: How are steel profiles used in the fabrication of conveyor systems?

- Steel profiles are commonly used in the fabrication of conveyor systems for various purposes. They serve as the structural framework for the system, providing stability and support. Steel profiles are often used to create the main beams, brackets, and other components that form the conveyor's frame. Additionally, they are utilized to construct the rollers and guides that facilitate the movement of the conveyor belt. Overall, steel profiles play a crucial role in ensuring the durability and functionality of conveyor systems.

- Q: What are the advantages of using steel for construction purposes?

- There are several advantages of using steel for construction purposes. Firstly, steel is a highly durable and strong material, making it capable of withstanding extreme weather conditions and heavy loads. Secondly, steel is versatile and can be easily shaped and molded into various forms, allowing for creative and innovative architectural designs. Additionally, steel is a sustainable and environmentally friendly choice as it can be recycled indefinitely without losing its quality. Moreover, steel structures require less maintenance compared to other materials, reducing long-term costs. Lastly, steel is fire resistant, providing enhanced safety and protection in case of a fire.

- Q: How is steel used in the production of storage tanks and containers?

- Steel is commonly used in the production of storage tanks and containers due to its strength, durability, and corrosion resistance. It provides a reliable and secure option for storing various fluids and materials, including water, chemicals, and petroleum products. Additionally, steel can be easily molded and fabricated into different shapes and sizes, making it versatile for different storage requirements.

- Q: How is steel used in the construction of infrastructure projects like roads and bridges?

- Steel is commonly used in the construction of infrastructure projects like roads and bridges due to its strength, durability, and versatility. It is utilized for reinforcing concrete structures, such as bridges and highway overpasses, providing the necessary support to withstand heavy loads and traffic. Steel is also used in the fabrication of beams, columns, and other structural elements, ensuring the stability and integrity of the overall infrastructure. With its resistance to corrosion and ability to withstand extreme weather conditions, steel plays a crucial role in enhancing the longevity and safety of roads and bridges.

- Q: What are the different types of steel profiles and sections available?

- There are various types of steel profiles and sections available, including I-beams, H-beams, U-channels, angles, square and rectangular tubes, round bars, and flat bars. These profiles and sections have different shapes and dimensions, allowing them to be used for various structural and construction purposes.

- Q: Can steel be used in the production of food-grade equipment?

- Yes, steel can be used in the production of food-grade equipment. Stainless steel, in particular, is commonly used due to its corrosion resistance, durability, and ease of cleaning. It is safe for direct contact with food and meets the hygiene and safety standards required for food production.

- Q: What are the advantages of using steel bars in construction?

- There are several advantages of using steel bars in construction. Firstly, steel bars are incredibly strong and have a high tensile strength, making them ideal for reinforcing concrete structures and providing stability. Secondly, steel bars are resistant to corrosion, which ensures the longevity and durability of the construction. Additionally, steel bars are versatile and can be easily shaped and molded according to the needs of the project. Moreover, steel bars are readily available in the market and have consistent quality standards, ensuring reliability in construction. Lastly, using steel bars in construction allows for faster construction timelines as they can be prefabricated off-site and easily transported to the construction site. Overall, the use of steel bars in construction offers strength, durability, versatility, and efficiency.

Send your message to us

Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords