Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Square Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

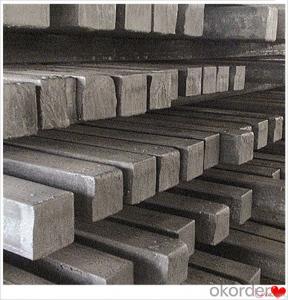

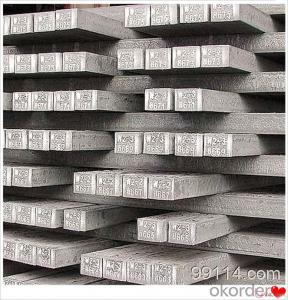

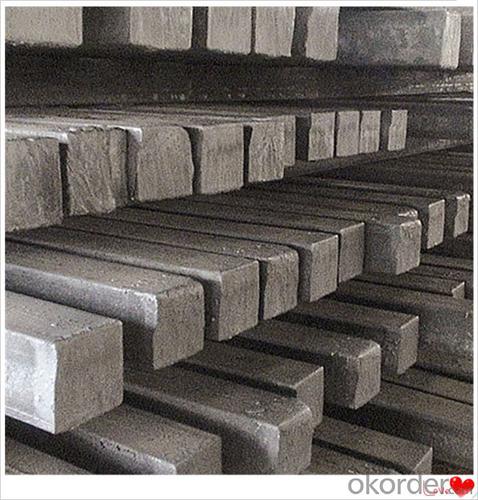

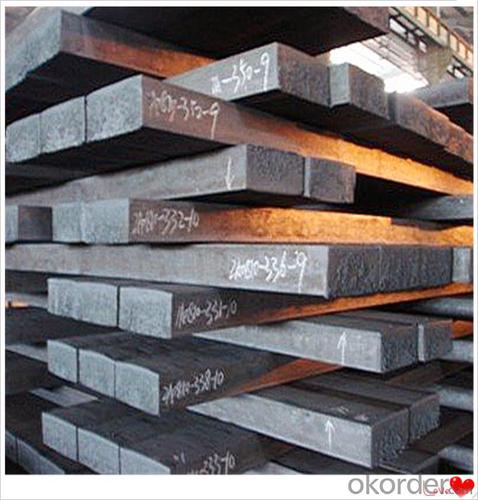

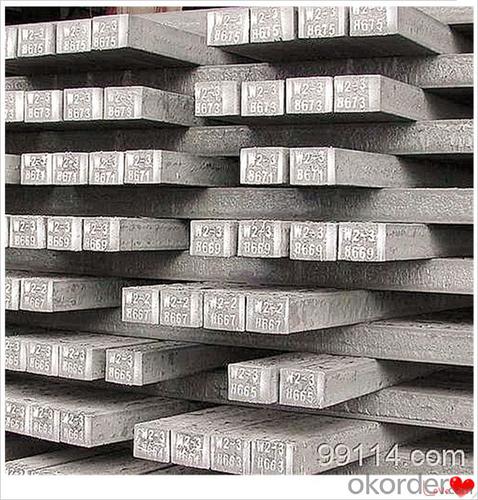

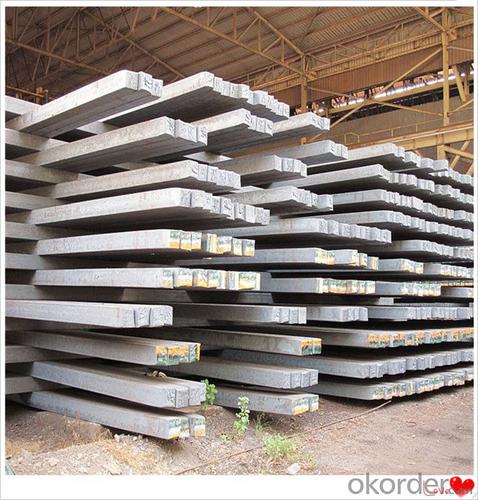

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the potential applications of steel billets in the medical industry?

- Steel billets have several potential applications in the medical industry. They can be used for the manufacturing of medical instruments, such as surgical tools, implants, and prosthetics, due to their strength, durability, and corrosion resistance. Steel billets can also be utilized in the production of medical equipment and machinery, such as MRI machines and X-ray tables, as they provide structural support and stability. Additionally, steel billets can be used for the fabrication of medical furniture and fixtures, like hospital beds and surgical tables, ensuring reliability and long-lasting performance in healthcare settings.

- Q: How are steel billets used in the production of marine vessels?

- Steel billets are used in the production of marine vessels as they serve as the raw material for various components and structures. These billets are typically shaped and processed to create different parts such as hulls, frames, decks, and superstructures. By being molded and welded together, steel billets provide the necessary strength, durability, and structural integrity required for marine vessels to withstand the harsh conditions of the sea.

- Q: What are the main challenges in steel billet production?

- There are several main challenges in steel billet production that manufacturers and producers face. One of the key challenges is ensuring consistent and uniform quality of the billets. Steel billets are the semi-finished products that are further processed into various steel products, and any inconsistency or variation in their quality can lead to defects or failures in the final products. Therefore, maintaining strict quality control measures throughout the production process is crucial. Another significant challenge is optimizing the production process to meet the desired quantity and quality targets while minimizing costs. This involves efficient utilization of resources such as raw materials, energy, and labor. Additionally, maintaining a balance between the production speed and quality can be challenging as increasing the speed may lead to reduced quality or increased defects. Ensuring the safety of workers and the environment is also a major challenge in steel billet production. The production process involves heavy machinery, high temperatures, and potentially hazardous materials, which can pose risks to the workers' health and safety. Implementing proper safety protocols, providing training, and ensuring compliance with regulatory standards are essential to address these challenges. Furthermore, meeting the ever-increasing demand for steel billets is a challenge for producers. The market demand fluctuates, and manufacturers need to be able to adjust their production capacity accordingly. This requires flexibility in production planning and efficient inventory management to avoid overproduction or stock shortages. Lastly, technological advancements and innovations in the steel industry pose both challenges and opportunities. Adopting new technologies, such as automation, artificial intelligence, and data analytics, can improve efficiency and productivity. However, incorporating these technologies into existing production processes can be complex and require significant investments and expertise. In summary, the main challenges in steel billet production include maintaining consistent quality, optimizing production processes, ensuring safety, meeting market demand, and adapting to technological advancements. Overcoming these challenges requires continuous improvement, innovation, and a proactive approach to stay competitive in the steel industry.

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Steel billets play a crucial role in the manufacturing of structural steel bridges as they serve as the primary raw material for the production of steel beams and other structural components. These billets are heated and then shaped into desired forms through processes like rolling or forging. Their high strength and durability make them ideal for constructing the load-bearing elements of bridges, ensuring the structural integrity and longevity of the final bridge product.

- Q: How are steel billets used in the production of transmission components?

- Steel billets are used in the production of transmission components as they serve as the raw material that is shaped, machined, and formed into various parts such as gears, shafts, and casings. These billets are heated, forged, and then processed through cutting, grinding, and milling operations to create the desired shape and size for each component. The strength and durability of steel make it an ideal material for transmission components, ensuring reliable and efficient operation in vehicles and machinery.

- Q: What are the different types of steel billet packaging?

- There are several types of steel billet packaging, including wooden crates, steel or plastic wrapping, and steel wire or strapping.

- Q: How are steel billets used in the production of automotive steering systems?

- Automotive steering systems rely heavily on steel billets, a crucial element in their manufacturing. These billets, typically crafted from high-quality steel, serve as the raw material for producing various steering system components like shafts, gears, and housings. The production process begins by heating and softening the steel billets to increase their malleability. This allows them to be easily molded and shaped into the desired steering system components through methods such as forging, rolling, or casting. The chosen technique depends on the complexity and function of the component being manufactured. Once the desired shape is achieved, the steel billets undergo further processing to enhance their strength and durability. This involves employing heat treatment techniques like quenching and tempering, which provide the steel with specific mechanical properties like improved hardness and toughness. These treatments ensure that the steering system components can handle the considerable loads and vibrations experienced during operation. After proper shaping and treatment, the billets undergo precision machining processes to attain the required dimensional accuracy and surface finish. This includes cutting, drilling, and grinding the billets to create the necessary profiles and features that enable optimal functioning within the steering system. Lastly, the finished steering system components are assembled together with other parts to create the complete automotive steering system. These components, manufactured from steel billets, play a critical role in transmitting driver input to the wheels, enabling precise control and maneuverability of the vehicle. In summary, steel billets are indispensable in the production of automotive steering systems as they provide the necessary strength, durability, and precision required for safe and efficient vehicle steering.

- Q: What is the role of steel billets in the construction of airports and terminals?

- Steel billets play a crucial role in the construction of airports and terminals due to their various advantageous properties. They are essentially semi-finished metal products that are used as a raw material in the manufacturing of different steel products. In the context of airports and terminals, steel billets are primarily utilized for the production of structural steel components such as beams, columns, and trusses. One of the key reasons why steel billets are preferred in the construction industry is their strength and durability. Steel is renowned for its high tensile strength, which allows it to withstand heavy loads and structural stresses. This makes it an ideal material for constructing large and complex structures like airports and terminals, where safety and reliability are paramount. Additionally, steel billets can be easily fabricated into various shapes and sizes, making them versatile for constructing different components required in airports and terminals. These billets are often hot rolled or forged into the desired shapes, ensuring that the resulting steel products have the necessary strength and structural integrity. Another crucial advantage of steel billets in the construction of airports and terminals is their resistance to adverse environmental conditions. Airports and terminals are exposed to harsh weather conditions, including extreme temperatures, moisture, and corrosion. Steel, especially when properly coated or treated, is highly resistant to these factors, ensuring the longevity and structural stability of the constructed facilities. Moreover, steel billets are relatively cost-effective compared to other construction materials, especially when considering their durability and low maintenance requirements. The long lifespan of steel structures reduces the need for frequent repairs or replacements, resulting in cost savings over time. In summary, steel billets play a vital role in the construction of airports and terminals by providing the necessary strength, durability, and versatility required for large-scale structures. Their ability to withstand heavy loads, resistance to environmental factors, and cost-effectiveness make them an ideal choice for such high-demand facilities.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: How are steel billets straightened after rolling or forging?

- Steel billets may become irregular or bent after the rolling or forging process. To rectify this, several methods can be utilized depending on the size and shape of the billets. One commonly used technique is rotary straightening. In this process, the billets are passed through a series of rotating rolls or wheels that gradually exert pressure on the material, resulting in straightening. The rolls are typically positioned at different angles to evenly distribute force across the billet. This method is suitable for smaller billets or those with minor bends. For larger and thicker billets, hydraulic straightening is often employed. Controlled pressure is applied at specific points along the length of the billet using hydraulic presses or jacks. By adjusting the pressure at different points, the billet is gradually straightened. This method is more appropriate for heavier and significantly bent billets. In certain instances, heat can be used to facilitate the straightening process. Heat straightening involves heating the bent section of the billet to a specific temperature and then applying pressure to straighten it while it is still hot. This method is particularly effective for billets with substantial bends or twists. It is crucial to emphasize that the straightening process necessitates precise control and monitoring to avoid over-straightening or excessive stress on the material. Skilled operators and advanced equipment are indispensable to ensure effective straightening of the billets within the desired tolerances.

Send your message to us

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords