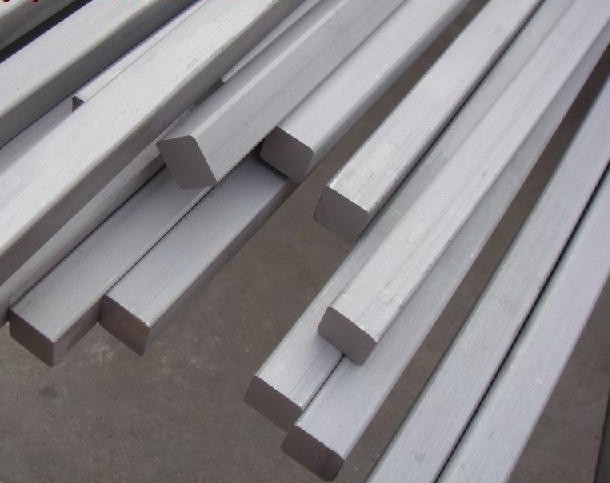

Squre Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q: Can a steel square be used for measuring the thickness of sheet metal?

- No, a steel square cannot be used for measuring the thickness of sheet metal as it is primarily used for checking right angles and measuring lengths or angles, not for measuring thickness.

- Q: Can a steel square be used for framing walls?

- Framing walls can be accomplished by utilizing a steel square. Known as a framing square or carpenter's square, this versatile tool is commonly employed in carpentry and framing endeavors. Typically crafted from steel, it possesses a 90-degree angle as well as a shorter 45-degree angle. When undertaking wall framing, a steel square proves invaluable in ensuring precise and square corners. It facilitates the measurement and marking of lumber, enables one to assess the squareness of walls, and guides the cutting and positioning of studs and other framing elements. By aligning the steel square's 90-degree angle with the wall's edges, the straightness and squareness of the framing are guaranteed. Furthermore, a steel square can be utilized for various other tasks related to wall framing, such as marking and cutting angles for roof rafters or stairs. Its durability and precision render it an indispensable tool for a multitude of framing duties, including wall construction.

- Q: Can a steel square be used for checking the squareness of a shelf?

- Yes, a steel square can be used for checking the squareness of a shelf. A steel square is a precision measuring tool that is designed to determine if a corner or edge is perfectly perpendicular or at a right angle. By placing the steel square against the corner of the shelf, one can easily check if it is square or not. If the square fits perfectly and the edges align with the sides of the shelf, then it is square. However, if there are gaps or the edges do not align, it indicates that the shelf is not square and may need adjustments. Overall, a steel square is a reliable tool for checking the squareness of a shelf and ensuring its stability and functionality.

- Q: Can a steel square be used for checking the squareness of a cabinet door opening?

- Yes, a steel square can be used for checking the squareness of a cabinet door opening. A steel square is a tool commonly used in woodworking and construction to ensure that corners and edges are perfectly square. It consists of a long arm and a shorter arm that meet at a 90-degree angle. By placing the steel square against the corners of the cabinet door opening, you can determine if the angles are perfectly square or if adjustments need to be made. This is important in ensuring that the cabinet door will fit properly and function correctly once installed.

- Q: How do you use a steel square to measure and mark out mitered joints?

- To use a steel square to measure and mark out mitered joints, follow these steps: 1. Start by ensuring that your steel square is clean and free from any debris or rust. This will help ensure accurate measurements. 2. Place the steel square on the edge of the material you are working with, aligning one leg of the square with the edge. 3. Hold the steel square firmly against the material and make sure it is flat against the surface. This will help prevent any potential inaccuracies. 4. Next, rotate the steel square until the desired angle for the mitered joint is achieved. This is typically a 45-degree angle for most mitered joints, but it may vary depending on the project or design. 5. Once the steel square is in the correct position, use a pencil or marking knife to trace along the edge of the square's other leg. This will create a clear and accurate line to guide your cuts. 6. Repeat this process for each piece of material that requires a mitered joint, ensuring that the angles and measurements are consistent across all pieces. 7. After marking out the mitered joints, double-check your measurements and angles to ensure accuracy before proceeding with any cutting or joining of the materials. It's important to note that using a steel square to measure and mark mitered joints requires precision and attention to detail. Taking your time and double-checking your measurements will help ensure that your mitered joints fit together perfectly and create a clean, professional finish.

- Q: Can a steel square be used for checking the alignment of posts?

- The alignment of posts can be checked using a steel square. This versatile and convenient tool is commonly employed in carpentry and woodworking. Its shape resembles a right angle with measurements marked on its edges. To ensure that the corners of the posts are at perfect right angles, a steel square can be utilized. This is crucial for maintaining the structural integrity and proper alignment of the posts. To check post alignment with a steel square, position one edge of the square against the side of the post and align it with the corner. Then, employ the other edge of the square to examine the alignment of the opposite side of the post. If the square fits perfectly against the post and the edges are aligned, it signifies that the post is properly aligned and at a right angle. Moreover, a steel square can also be employed to verify the levelness of the posts. By placing the square against the top surface of the post, you can determine if the post is level or requires adjustment. In conclusion, the alignment of posts can be assessed effectively using a steel square. It guarantees the right angles of the corners and enables the verification of levelness for the posts.

- Q: Are there any specialty steel squares available for specific tasks?

- Indeed, there exist specialized steel squares tailored to specific tasks. Steel squares serve as versatile tools utilized across various industries, including carpentry, metalworking, and engineering. While standard steel squares suffice for most tasks, there are specialized variants designed to meet particular requirements. For instance, within woodworking, there are specialty steel squares referred to as rafter squares or carpenter's squares. These squares possess additional features such as tables or scales that assist in measuring angles and executing intricate cuts for rafters, stairs, and other applications. Within metalworking, there are steel squares explicitly crafted for welding and fabrication tasks. These squares often feature heat-resistant coatings or materials to endure the elevated temperatures associated with welding. They may also possess precise measurements and markings to ensure accurate layout and alignment. In the realm of engineering and machining, precision steel squares find common usage. These squares are manufactured with exceptional accuracy and tight tolerances, guaranteeing precise measurements and alignment. They are frequently employed in machinery setup, angle verification, and perpendicularity checks. Furthermore, certain specialty steel squares are devised for specific trades or industries. For instance, masonry squares made from steel with rust-resistant coatings cater to bricklaying and other masonry tasks. Similarly, roofing squares equipped with angled scales and markings enable roofers to measure and cut with utmost precision. In conclusion, specialty steel squares address the unique demands of diverse tasks and industries. Whether it be woodworking, metalworking, engineering, or other trades, there likely exists a specialized steel square capable of enhancing precision, accuracy, and efficiency within those specific applications.

- Q: Can a steel square be used for insulation installation?

- Using a steel square for insulation installation is not possible. Steel squares are commonly utilized in construction and woodworking to measure and indicate right angles. However, insulation installation necessitates materials that can offer thermal resistance, such as fiberglass, foam board, or mineral wool. These materials are specifically engineered to capture air and hinder heat transfer, a capability that steel squares lack. Consequently, it is crucial to employ suitable insulation materials for a successful installation.

- Q: Can a steel square be used for checking the squareness of a drill press table?

- No, a steel square is not suitable for checking the squareness of a drill press table. It is designed for measuring and marking right angles, but it does not provide the necessary accuracy and precision required for checking the squareness of a drill press table. A specialized tool such as a precision square or a machinist's square should be used for this purpose.

- Q: How do you use a steel square to lay out a jack rafter with unequal pitch?

- To use a steel square to lay out a jack rafter with unequal pitch, you would first determine the desired pitch for the rafter. Then, using the steel square, align the pivot point with the plumb line of the ridge board and the desired pitch line on the tongue. Next, mark the run of the rafter on the blade of the square. Finally, transfer the marked measurements onto the rafter board and cut accordingly to create the jack rafter with unequal pitch.

Send your message to us

Squre Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords