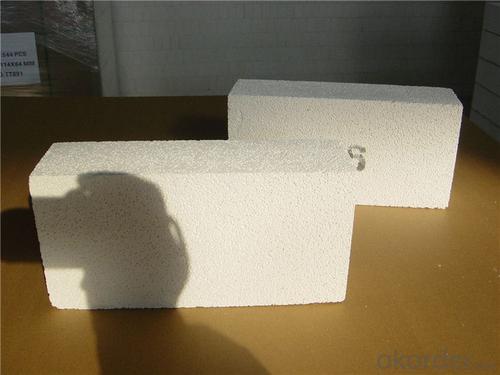

Insulating Fire Brick - Standard Size Refractory Materials for Foundry & Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Insulating Fire Brick Technical index

Brand Quality | JM23 | JM26 | JM28 | JM30 | JM32 | |

Bulk Density (g/cm3) | 0.52 | 0.78 | 0.88 | 1.03 | 1.25 | |

1.2 | 1.6 | 2.1 | 2.5 | 3.5 | ||

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

-0.5 | 1400℃ -0.4 | 1510℃ -0.5 | 1620℃ -0.9 | 1730℃ -0.9 | ||

Thermal Expansion 1100℃(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k)

| 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.50 | |

800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 | 0.7 | 0.7 | 0.6 | 0.5 | 0.4 | |

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Can insulating fire bricks be used in the construction of ovens or kilns for pottery?

- Yes, insulating fire bricks can be used in the construction of ovens or kilns for pottery. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. They have a low thermal conductivity, which means they can effectively retain heat and prevent heat loss, making them ideal for creating and maintaining high temperatures required in pottery ovens or kilns. Additionally, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This makes them a reliable choice for constructing ovens or kilns that need to undergo frequent heating and cooling cycles. Overall, insulating fire bricks are a popular choice in pottery oven or kiln construction due to their thermal insulation properties and durability.

- Q: Do insulating fire bricks have a high fireproof rating?

- Insulating fire bricks indeed have a high fireproof rating. These bricks are specifically designed to withstand extremely high temperatures and provide excellent insulation against heat transfer. They are made from special refractory materials that have low thermal conductivity, which helps in retaining heat and preventing it from escaping the system. Insulating fire bricks can withstand temperatures ranging from 2300°F to 3100°F (1260°C to 1700°C), making them ideal for use in furnaces, kilns, fireplaces, and other high-temperature applications. Their high fireproof rating ensures that they can effectively protect structures and equipment from the intense heat and flames, allowing for safe and efficient operation in various industries.

- Q: Are insulating fire bricks suitable for insulation in refinery heaters?

- Insulating fire bricks are indeed suitable for insulation in refinery heaters. These heaters operate at extremely high temperatures, and the insulating fire bricks are specifically designed to withstand these temperatures and provide efficient insulation. With their low thermal conductivity, these bricks effectively prevent heat from escaping the heater, thereby reducing energy loss and improving the overall efficiency of the heater. Moreover, these bricks possess exceptional thermal shock resistance, enabling them to endure sudden temperature changes without cracking or breaking. Given the frequent temperature fluctuations experienced by refinery heaters, this quality is essential. Furthermore, the lightweight nature and easy installation process of insulating fire bricks make them a convenient choice for insulation in refinery heaters. Ultimately, insulating fire bricks prove to be an appropriate and efficient option for insulation in refinery heaters.

- Q: Can insulating fire bricks be used in crucibles?

- Crucibles do not allow the use of insulating fire bricks. Insulating fire bricks are primarily meant for insulation purposes in kilns, furnaces, and fireplaces, where low thermal conductivity is desirable. On the other hand, crucibles necessitate materials with high thermal conductivity and resistance to endure the intense heat and chemical reactions involved in processes like metal melting or refining, conducting high-temperature experiments, or performing chemical reactions. Consequently, crucibles are generally constructed using materials like graphite, clay, or ceramic, which can withstand the extreme conditions and facilitate efficient heat transfer.

- Q: Is it necessary to abolish the technical regulations for the construction of self thermal insulation masonry building with sludge sintering insulation bricks?

- The original "technical specification for self insulation masonry building with silt insulation bricks" has been replaced by DGJ32/TJ78-2009 (technical specification for automatic insulation wall system of sintered silt non bearing insulating brick) DGJ32/TJ78-2013.

- Q: Do insulating fire bricks require curing after installation?

- Insulating fire bricks do not need to be cured after installation. Unlike other fire bricks, they are made from lightweight materials that are moisture-free and do not require curing. These bricks offer exceptional insulation and heat resistance, making them perfect for kilns, furnaces, and fireplaces. Once they are installed, insulating fire bricks can be used right away without any additional curing or drying time needed.

- Q: Are insulating fire bricks resistant to phosphorus pentoxide?

- Yes, insulating fire bricks are resistant to phosphorus pentoxide.

- Q: Are insulating fire bricks suitable for use in the construction of blast furnaces?

- Yes, insulating fire bricks are suitable for use in the construction of blast furnaces. These bricks have excellent insulating properties, high refractoriness, and thermal shock resistance, making them capable of withstanding the extreme temperatures and rapid temperature changes commonly encountered in blast furnaces. Additionally, their lightweight nature allows for easier installation and reduces the overall weight of the furnace structure.

- Q: Can insulating fire bricks be used in glass furnaces?

- Yes, insulating fire bricks can be used in glass furnaces. Insulating fire bricks are designed to have low thermal conductivity, which makes them ideal for use in high-temperature environments like glass furnaces. These bricks help to reduce heat loss from the furnace, resulting in improved energy efficiency and reduced operating costs. They also provide better insulation and help to maintain consistent temperatures inside the furnace, which is crucial for glass production. Additionally, insulating fire bricks have good resistance to thermal shock and can withstand the extreme temperatures and rapid temperature changes that occur in glass furnaces. Overall, the use of insulating fire bricks in glass furnaces can contribute to better furnace performance, increased productivity, and energy savings.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Insulating fire bricks are a suitable choice for steel manufacturing plants. Their excellent thermal properties, including high heat resistance and low thermal conductivity, make them ideal for high-temperature environments like steel manufacturing plants. These bricks can endure the extreme heat generated during steel production processes such as melting, casting, and forging. Furthermore, they assist in conserving energy by minimizing heat loss, thereby enhancing the overall efficiency of the plant. Additionally, they possess considerable mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. In summary, incorporating insulating fire bricks in steel manufacturing plants can enhance safety, boost productivity, and improve energy efficiency.

Send your message to us

Insulating Fire Brick - Standard Size Refractory Materials for Foundry & Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords