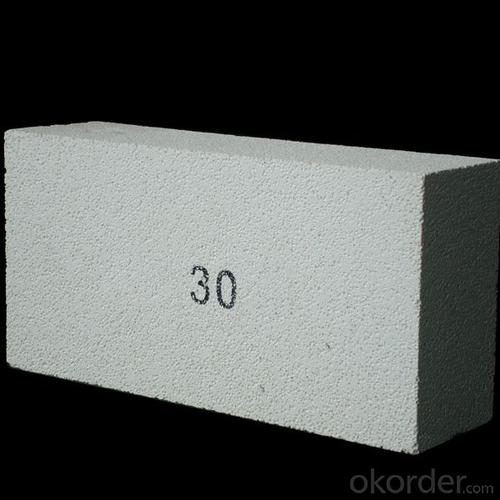

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick

Our insulating firebricks are classified under temperature range from 1300℃ to 1700℃.Our insulating fire bricks are manufactured from high purity alumina clay.

Feature of Insulating Fire Brick

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Fire Brick

Our insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data of of Insulating Fire Brick

- Q: Do insulating fire bricks have a low density?

- Yes, insulating fire bricks typically have a low density compared to other types of bricks.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Insulation in walls and roofs can be achieved by utilizing insulating fire bricks. These bricks are constructed from lightweight materials that possess exceptional thermal insulation properties. Their thermal conductivity is low, allowing them to effectively minimize heat transfer through walls and roofs. Consequently, they are a fitting selection for enhancing energy efficiency and insulating buildings. Furthermore, insulating fire bricks are both long-lasting and fire-resistant, rendering them a secure choice for insulation. Nevertheless, it is crucial to acknowledge that these bricks are typically employed in high-temperature environments such as furnaces and kilns. Thus, they might not be the most economical or practical option for all wall and roof insulation requirements. In terms of cost, installation ease, and overall performance, other insulation materials specifically designed for building applications may be more appropriate.

- Q: Can insulating fire bricks be used as a lining for boilers?

- Indeed, boilers can make use of insulating fire bricks as linings. These bricks are specifically engineered to endure extreme temperatures and possess outstanding thermal insulation capabilities. Their prevalent application lies in contexts where conserving heat and promoting energy efficiency are paramount, notably in industrial boiler settings. The insulating properties inherent in these bricks facilitate the reduction of heat dissipation and enhance the overall efficiency of the boiler. Furthermore, their robustness and ability to withstand thermal shock render them fitting for deployment within boiler linings, where they can endure the harshest conditions and temperature fluctuations.

- Q: Do insulating fire bricks require any curing or drying time?

- Absolutely not! Insulating fire bricks do not need any curing or drying time whatsoever. These bricks are produced through high-temperature methods, resulting in a completely cured and dried product. Consequently, they can be utilized right after installation without any requirement for extra curing or drying time.

- Q: Are insulating fire bricks suitable for insulation in boilers for steam generation?

- Insulating fire bricks are a suitable choice for insulation in steam generation boilers. Specifically designed to possess exceptional thermal insulation properties, these bricks are perfect for high-temperature applications like boilers. With their low thermal conductivity, they effectively minimize heat transfer and prevent heat loss. This insulation capability aids in maintaining optimal temperatures within the boiler, thereby enhancing energy efficiency and reducing fuel consumption. Moreover, these bricks can withstand thermal shock, making them highly resistant to the extreme temperature fluctuations encountered during steam generation. Overall, incorporating insulating fire bricks into steam generation boilers can significantly improve the system's thermal efficiency and performance.

- Q: Are insulating fire bricks suitable for insulation in petrochemical plants?

- Insulating fire bricks, which are composed of lightweight materials with exceptional insulating properties like ceramic fibers or lightweight refractory aggregates, are well-suited for insulation in petrochemical plants. These bricks possess a low thermal conductivity that effectively curbs heat transfer and provides insulation in high-temperature settings. In petrochemical plants, where the manipulation of flammable and hazardous substances occurs, maintaining proper insulation is of utmost importance for safety and efficiency. By withstanding extreme temperatures and delivering superb thermal insulation, insulating fire bricks effectively curtail heat loss and diminish energy consumption. Moreover, insulating fire bricks exhibit resistance to chemical corrosion, rendering them suitable for deployment in petrochemical plants frequently exposed to corrosive chemicals. Additionally, these bricks demonstrate durability and commendable mechanical strength, enabling them to endure the harsh conditions typically encountered in petrochemical plants. All in all, insulating fire bricks emerge as the ideal choice for insulation in petrochemical plants due to their capacity to withstand high temperatures, exceptional thermal insulation properties, resistance to chemical corrosion, and remarkable durability.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- It is not possible to use insulating fire bricks in ceramic fiber blankets. Insulating fire bricks are dense and solid, specifically designed to offer insulation and endure high temperatures in settings like furnaces and kilns. Conversely, ceramic fiber blankets are flexible and lightweight, consisting of ceramic fibers that provide exceptional thermal insulation. They are frequently utilized as insulation in diverse industrial applications, such as lining for furnaces, boilers, and high-temperature equipment. Combining insulating fire bricks with ceramic fiber blankets would not yield effective results because these materials possess distinct properties and serve different purposes.

- Q: How do insulating fire bricks affect the overall durability of a structure?

- Insulating fire bricks play a crucial role in enhancing the overall durability of a structure. These bricks are designed to have a low thermal conductivity, which means they are effective in resisting heat transfer. By reducing the amount of heat that passes through the bricks, they help to maintain a stable temperature within the structure, protecting it from extreme temperature variations. One of the key benefits of insulating fire bricks is their ability to withstand high temperatures. They have a high melting point, which allows them to retain their structural integrity even in the presence of intense heat. This quality is particularly important in structures where high temperatures are generated, such as furnaces or kilns. The ability of insulating fire bricks to handle such extreme temperatures greatly contributes to the durability of the structure. Furthermore, insulating fire bricks offer excellent insulation properties. Their low thermal conductivity prevents heat from escaping or entering the structure, leading to energy efficiency. This not only reduces energy consumption but also protects the structure from potential damage caused by excessive heat loss. By maintaining a consistent temperature, insulating fire bricks prevent thermal expansion and contraction, which can lead to cracks and structural instability. In addition to their heat resistance and insulation properties, insulating fire bricks are also known for their resistance to chemical corrosion. Many structures are exposed to harsh environments or chemicals that can cause degradation. However, insulating fire bricks are made from materials that are resistant to chemical reactions, ensuring their durability and longevity. Overall, the use of insulating fire bricks significantly enhances the durability of a structure. Their ability to withstand high temperatures, provide insulation, and resist chemical corrosion make them a valuable component in various industrial and residential applications. By ensuring a stable and protected environment, insulating fire bricks contribute to the long-lasting and reliable performance of the structure.

- Q: How thick are insulating fire bricks?

- Insulating fire bricks typically range in thickness from 1 to 3 inches.

- Q: Do insulating fire bricks require preheating before use?

- Yes, insulating fire bricks typically require preheating before use. Preheating helps to eliminate any moisture present in the bricks and prevent thermal shock when exposed to high temperatures. This process ensures their stability and enhances their insulation properties.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 10.00% Northern Europe 30.00% North America 30.00% Eastern Asia 5.00% Africa 10.00% Southeast Asia 15.00% Western Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 16,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High-Performance Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Pcs m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords