Insulating Fire Brick - High Quality Clay Refractory Insulating Fire Brick for Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

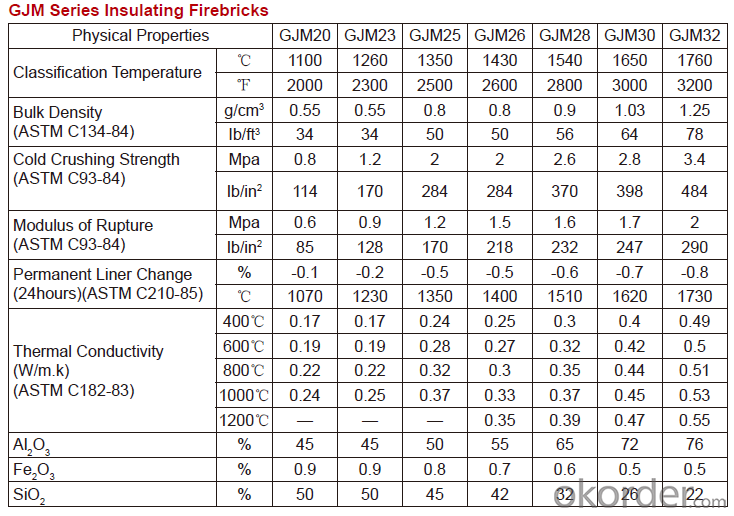

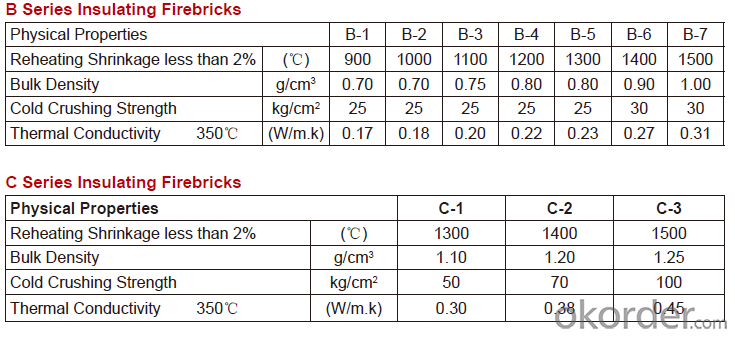

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

Insulating Fire Brick main feature

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Do insulating fire bricks require any special curing or firing temperature profiles?

- Yes, insulating fire bricks do require special curing and firing temperature profiles. Insulating fire bricks are made from lightweight materials such as perlite, vermiculite, or alumina silicate, which have high insulating properties. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. During the manufacturing process, insulating fire bricks go through a curing process to remove any moisture content. This is typically done by gradually increasing the temperature in a controlled manner. The curing process is important to prevent any cracking or damage that could occur if the bricks were exposed to high temperatures too quickly. In terms of firing temperature profiles, insulating fire bricks require careful consideration. They are designed to be used in applications where temperatures reach up to 2800°F (1538°C). Therefore, it is crucial to follow the recommended firing temperature profiles provided by the manufacturer. The firing temperature profile typically involves a gradual increase in temperature to allow the insulating fire bricks to reach the desired maximum temperature without causing any thermal shock or damage. This slow heating process ensures that the bricks are properly cured and can withstand the extreme temperatures they will be exposed to during use. It is important to note that the specific curing and firing temperature profiles may vary depending on the type and composition of the insulating fire bricks. Therefore, it is essential to refer to the manufacturer's guidelines and recommendations to ensure the proper curing and firing process for the specific type of insulating fire bricks being used.

- Q: What industries commonly use insulating fire bricks?

- Insulating fire bricks are commonly used in industries such as steel, aluminum, ceramics, glass, and cement production, as well as in various high-temperature applications like furnaces, kilns, incinerators, and thermal insulation systems.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Yes, insulating fire bricks are resistant to chlorine gas.

- Q: Can insulating fire bricks be used in the construction of heat recovery systems?

- Yes, insulating fire bricks can be used in the construction of heat recovery systems. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them an ideal choice for heat recovery systems. These bricks are made from lightweight materials, such as ceramic fibers or refractory materials, which have low thermal conductivity. This property allows them to effectively trap and retain heat, preventing it from escaping the system and maximizing energy efficiency. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This makes them suitable for the varying heat conditions often found in heat recovery systems. Overall, using insulating fire bricks in the construction of heat recovery systems can help improve their performance and efficiency by minimizing heat loss and optimizing energy recovery.

- Q: Do insulating fire bricks require any special sealing or caulking?

- In certain applications, insulating fire bricks typically require special sealing or caulking. Despite their ability to withstand high temperatures and provide excellent thermal insulation, insulating fire bricks can still be vulnerable to moisture infiltration and atmospheric gases in specific environments. To address these risks, sealing or caulking is often necessary. To seal or caulk insulating fire bricks, specialized refractory materials or compounds that can withstand high temperatures and create an airtight barrier are used. This sealing process helps prevent moisture, gases, and other contaminants from compromising the insulating properties of the bricks. The specific sealing or caulking method depends on the application and type of insulating fire bricks being used. Common techniques include using high-temperature silicone sealants, refractory mortars, or coatings. These materials are specifically designed to endure the extreme temperatures found in high-heat environments. It is important to consult the manufacturer's guidelines or seek professional advice when determining the appropriate sealing or caulking method for insulating fire bricks. Proper sealing ensures the insulation's longevity, effectiveness, and overall performance and safety of the application.

- Q: Are insulating fire bricks resistant to erosion?

- Yes, insulating fire bricks are generally resistant to erosion. Insulating fire bricks are made of lightweight materials such as alumina, silica, or a combination of both. These materials have excellent resistance to erosion caused by high temperatures, chemical reactions, and physical wear. They are designed to withstand extreme heat and harsh conditions, making them highly durable against erosion. Additionally, insulating fire bricks have low thermal conductivity, which means that they do not absorb or transfer heat easily, further protecting them from erosion. However, it is important to note that the resistance to erosion may vary depending on the specific composition and quality of the insulating fire bricks.

- Q: Can insulating fire bricks be used for high-temperature applications?

- Yes, insulating fire bricks are commonly used for high-temperature applications. These bricks are specifically designed to provide excellent thermal insulation and withstand extreme temperatures. They can typically withstand temperatures of up to 2600°F (1427°C) or even higher depending on the specific type and composition of the brick. Insulating fire bricks are commonly used in kilns, furnaces, and industrial applications where high temperatures are required. They are known for their low thermal conductivity, which helps to minimize heat loss and increase energy efficiency. Additionally, these bricks are lightweight, durable, and resistant to thermal shock, making them ideal for high-temperature environments.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Insulation in heat exchangers can be achieved by utilizing insulating fire bricks. These bricks are constructed from a lightweight refractory material that boasts exceptional thermal insulation properties. With their low thermal conductivity, insulating fire bricks effectively minimize heat transfer between the two sides of the heat exchanger. Consequently, they aid in maintaining the desired temperature within the heat exchanger and prevent heat loss to the surroundings. Furthermore, the durability of these bricks is evident as they can endure high temperatures and thermal shocks, making them ideal for the harsh conditions typically encountered in heat exchangers. In summary, incorporating insulating fire bricks into heat exchangers not only enhances energy efficiency and reduces heat loss but also improves the overall system performance.

- Q: Do insulating fire bricks have a high resistance to creep?

- Insulating fire bricks possess a notable resistance to creep, indicating their ability to resist deformation over time when subjected to a consistent load or stress. Their design enables them to endure high temperatures and retain their form and integrity despite prolonged exposure to heat. These bricks are composed of lightweight refractory materials like clay, which exhibit low thermal conductivity and exceptional resistance to thermal shock. The amalgamation of these characteristics empowers insulating fire bricks to withstand creep and uphold their structural stability, even in the most challenging and extreme circumstances.

- Q: Can insulating fire bricks be used for insulation in power generation plants?

- Insulation in power generation plants can be achieved by utilizing insulating fire bricks. These bricks are specifically designed to have low thermal conductivity, making them ideal for applications that require high-temperature insulation. Given the high temperatures at which power generation plants operate, efficient insulation is crucial to minimize heat loss and enhance energy efficiency. Insulating fire bricks are crafted from lightweight materials like clay, alumina, and silica, all of which possess exceptional insulating properties. These bricks can endure extreme temperatures ranging from 1260°C to 1790°C (2300°F to 3250°F), depending on their specific composition and grade. Consequently, they are suitable for the intense heat conditions typically encountered in power generation plants. Moreover, insulating fire bricks exhibit resistance to thermal shock, which is particularly significant in power generation plants due to the frequent and intense heating and cooling processes. The ability of these bricks to withstand thermal shock ensures the durability of the insulation, minimizing the need for frequent replacements and maintenance. In addition to their outstanding thermal insulation properties, insulating fire bricks offer other advantages. They are lighter in weight compared to traditional refractory bricks, making them easier to handle and install. This feature can save time and labor during construction or maintenance tasks in power generation plants. All in all, insulating fire bricks are a reliable and efficient choice for insulation in power generation plants. They provide high-temperature insulation, resistance to thermal shock, and easy installation, making them an ideal solution to enhance the energy efficiency and performance of power generation facilities.

Send your message to us

Insulating Fire Brick - High Quality Clay Refractory Insulating Fire Brick for Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords