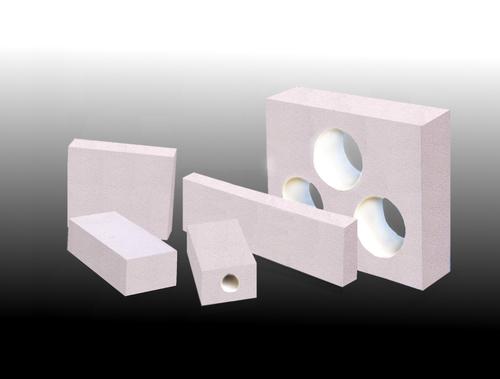

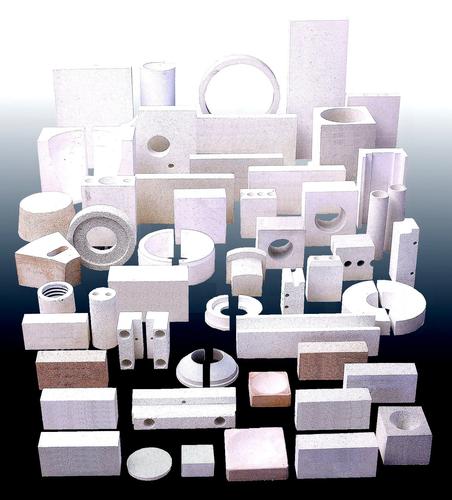

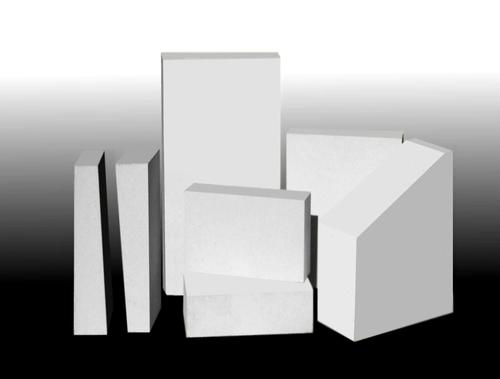

Customized Shape Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in low-temperature applications as well?

- Yes, insulating fire bricks can be used in low-temperature applications. These bricks are designed to have low thermal conductivity, making them suitable for retaining heat and insulating against temperature fluctuations. They can effectively withstand lower temperatures while still providing insulation and preventing heat loss.

- Q: Are insulating fire bricks suitable for insulation in heat treatment furnaces?

- Yes, insulating fire bricks are suitable for insulation in heat treatment furnaces. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have a low thermal conductivity, which helps to minimize heat loss and maintain a stable temperature inside the furnace. Insulating fire bricks are also lightweight, making them easier to handle and install. Additionally, they have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Overall, insulating fire bricks are a reliable and effective choice for insulation in heat treatment furnaces.

- Q: Are insulating fire bricks resistant to nitrogen oxides?

- Insulating fire bricks are known for their excellent thermal insulation properties and are commonly used in high-temperature applications such as furnaces, kilns, and industrial boilers. While they are highly resistant to heat and can withstand extreme temperatures, their resistance to nitrogen oxides (NOx) may vary depending on the specific composition and manufacturing process of the bricks. Nitrogen oxides are a group of harmful gases that are produced during combustion processes, particularly at high temperatures. These gases can have detrimental effects on human health and the environment. Although insulating fire bricks have a high melting point and can withstand intense heat, they may not provide sufficient resistance to nitrogen oxides on their own. To enhance the resistance of insulating fire bricks to nitrogen oxides, additional measures and coatings may be required. These could include the use of specialized refractory coatings or the incorporation of specific additives during the manufacturing process to create a more chemically resistant brick. It is important to note that the resistance of insulating fire bricks to nitrogen oxides may also depend on the specific application and operating conditions. Different types of nitrogen oxides, such as nitrogen dioxide (NO2) or nitric oxide (NO), may have different effects on the bricks. Therefore, it is recommended to consult the manufacturer or a specialist in refractory materials to determine the suitability of insulating fire bricks in a specific environment where the presence of nitrogen oxides is a concern.

- Q: Can insulating fire bricks be used as a heat shield?

- Insulating fire bricks can serve as an effective heat shield due to their excellent thermal insulation properties. These bricks are specifically designed to block and reflect heat, making them suitable for applications where heat containment or redirection is necessary. Fireplaces, kilns, furnaces, and industrial ovens commonly utilize insulating fire bricks to manage heat. By reducing heat transfer, these bricks create a protective barrier between the intense heat source and the surrounding environment. Moreover, their high melting points and ability to withstand high temperatures make them ideal for use as heat shields. However, it should be noted that the effectiveness of insulating fire bricks as a heat shield may vary depending on the specific requirements and conditions of the application.

- Q: Can insulating fire bricks be used in the construction of melting furnaces?

- Yes, insulating fire bricks can be used in the construction of melting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in melting furnaces where heat retention is crucial.

- Q: Do insulating fire bricks require any special sealing or caulking?

- Insulating fire bricks generally do not require any special sealing or caulking. These bricks are designed to have low thermal conductivity, which means they already provide good insulation on their own. However, in certain specific applications or when exposed to extreme temperatures, some sealing or caulking may be necessary to ensure optimal performance and prevent any heat loss or damage. It is recommended to consult the manufacturer's guidelines or a professional for specific sealing requirements in such cases.

- Q: What is the compressive strength of insulating fire bricks?

- The specific composition and manufacturing process of insulating fire bricks can cause variations in their compressive strength. Generally, these bricks have a compressive strength ranging from 1 to 10 MPa. This range is comparatively lower than that of other types of bricks due to their lightweight and porous nature. This design allows them to offer exceptional thermal insulation properties. It is worth noting that the compressive strength of insulating fire bricks may not be as significant as it is for structural bricks. Their primary purpose is to provide insulation rather than structural support.

- Q: How durable are insulating fire bricks?

- Insulating fire bricks are highly durable due to their high temperature resistance and ability to withstand thermal shock. They can withstand extreme heat, making them suitable for various industrial applications such as furnaces, kilns, and incinerators. Additionally, their insulating properties help reduce energy consumption by minimizing heat loss, making them a long-lasting and cost-effective solution for insulation needs.

- Q: What is the typical moisture content of an insulating fire brick?

- The typical moisture content of an insulating fire brick is usually less than 1%.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Insulating fire bricks are commonly known for their remarkable thermal shock resistance. They are specifically engineered to endure sudden temperature variations without any fractures or damage. Crafted from lightweight refractory materials with low thermal conductivity, these bricks effectively reduce heat transfer and prevent thermal strain. Furthermore, the firing process they undergo further enhances their ability to withstand thermal shocks. In summary, these bricks are perfect for situations where extreme temperature fluctuations are encountered, making them a dependable option for insulation in high-temperature surroundings.

Send your message to us

Customized Shape Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 17 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords