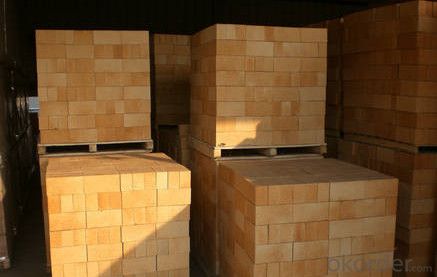

Insulating Fire Brick - High Alumina Lightweight Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Brief discription for Alumina Fire Brick

CNBM Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%.

CNBM Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for Alumina Fire Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high aluminia bricks

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

Why us

Professional fire brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

- Q: How to reinforce a porous brick foundation?

- The basic type method is changed from independent basis to strip foundation, from strip foundation to raft foundation and pile foundation, from brick to concrete strip foundation.

- Q: Do insulating fire bricks require a protective coating?

- Insulating fire bricks do not necessarily require a protective coating, as they are already designed to withstand high temperatures and provide insulation. These bricks are made from lightweight refractory materials that have excellent thermal conductivity properties, allowing them to retain heat and prevent heat transfer. However, in some specific applications where the bricks may come into contact with corrosive materials or aggressive chemicals, a protective coating may be necessary to enhance their durability and resistance. Ultimately, the need for a protective coating depends on the specific usage and environment in which the insulating fire bricks are being used.

- Q: Can insulating fire bricks be used in residential fireplaces?

- Yes, insulating fire bricks can be used in residential fireplaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for fireplace construction. These bricks can help retain heat, increase energy efficiency, and prevent heat loss. They also offer superior protection against thermal shock, which is essential for withstanding the intense heat generated by a fireplace. Additionally, insulating fire bricks are lightweight, easy to handle, and can be easily shaped or cut to fit any fireplace design or size. Overall, using insulating fire bricks in residential fireplaces is a wise choice for homeowners looking to enhance the performance and safety of their fireplace.

- Q: Can insulating fire bricks be used in rocket stove designs?

- Insulating fire bricks are capable of being incorporated into the designs of rocket stoves. Rocket stoves are renowned for their efficient combustion and heat transmission, and the utilization of insulating fire bricks can enhance this level of performance. These bricks are produced from lightweight materials that possess excellent insulating properties, allowing them to effectively retain and reflect heat. The combustion chamber of a rocket stove is typically lined with insulating fire bricks in order to maximize the transfer of heat to the cooking surface or the area being heated. The bricks aid in the retention of heat within the combustion chamber, ensuring that a greater portion of the energy generated from the burning fuel is utilized to heat the cooking surface, rather than being dissipated into the surrounding environment. Moreover, insulating fire bricks are capable of enduring high temperatures, making them an ideal choice for inclusion in rocket stove designs. They are specifically engineered to withstand the intense heat generated by the combustion process, guaranteeing that the bricks will not fracture or shatter under such circumstances. In conclusion, the incorporation of insulating fire bricks into the designs of rocket stoves can enhance the efficiency and heat transmission of the stove, resulting in a more efficient and sustainable solution for cooking or heating purposes.

- Q: Are insulating fire bricks suitable for outdoor use?

- Insulating fire bricks are not typically suitable for outdoor use due to their lower density and higher porosity compared to other types of bricks. These bricks are designed for use in high-temperature applications such as furnaces and kilns, where they provide excellent insulation properties. However, when exposed to the elements, insulating fire bricks may absorb moisture and be prone to cracking or deteriorating over time. For outdoor applications, it is generally recommended to use dense fire bricks or other types of bricks that are specifically designed for outdoor use, as they have greater durability and resistance to weather conditions.

- Q: How thick should the insulation layer be when using insulating fire bricks?

- The thickness of the insulation layer when using insulating fire bricks depends on various factors such as the desired level of insulation, the temperature of the surrounding environment, and the specific application or purpose of the insulation. In general, insulating fire bricks are designed to provide excellent thermal insulation, which means they are capable of reducing heat transfer effectively. However, the thickness of the insulation layer should be determined based on the specific requirements of the project. For applications where high-temperature insulation is needed, a thicker layer of insulating fire bricks is typically recommended. This is because a thicker layer can provide better insulation and reduce heat loss more effectively. Additionally, a thicker insulation layer can also enhance the overall structural integrity of the insulation system. On the other hand, for applications where lower temperature insulation is needed or for projects with space constraints, a thinner layer of insulating fire bricks may be sufficient. In such cases, it is important to consider the specific thermal conductivity properties of the insulating fire bricks being used and ensure that the desired insulation requirements are met. It is also worth noting that insulation requirements may vary based on local building codes, safety regulations, and industry standards. Therefore, it is advisable to consult with professionals or experts in the field to determine the optimal thickness of the insulation layer when using insulating fire bricks for a specific project.

- Q: Can insulating fire bricks be used in glass furnaces?

- Yes, insulating fire bricks can be used in glass furnaces. They are commonly used to line the walls and roofs of glass furnaces to reduce heat loss, improve energy efficiency, and provide thermal insulation.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Yes, insulating fire bricks can be used in boilers for residential heating. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation properties. These bricks are commonly used in the construction of boilers and furnaces due to their ability to retain heat and prevent heat loss. They can help improve the energy efficiency of the boiler system by reducing heat transfer to the surroundings, allowing for more efficient heating and lower energy consumption. Additionally, insulating fire bricks are durable and resistant to thermal shock, making them suitable for the high temperatures and rapid temperature changes commonly experienced in boilers. Therefore, using insulating fire bricks in residential heating boilers can help improve their performance and energy efficiency.

- Q: Can insulating fire bricks be used in high-temperature insulation applications?

- Yes, insulating fire bricks can be used in high-temperature insulation applications. Insulating fire bricks are designed to withstand and retain heat at elevated temperatures. They have low thermal conductivity and high insulation properties, making them ideal for use in applications where high temperatures need to be contained and insulated. These bricks are commonly used in industries such as steel, glass, and ceramics, as well as in furnaces, kilns, and other high-temperature equipment. Insulating fire bricks provide a reliable and efficient solution for insulation in high-temperature environments, helping to maintain heat and reduce energy loss.

- Q: Can insulating fire bricks be used as a lining for chimneys?

- Yes, insulating fire bricks can be used as a lining for chimneys. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining chimneys and protecting them from heat damage.

Send your message to us

Insulating Fire Brick - High Alumina Lightweight Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords