Insulating Fire Brick - Refractory Insulating Fire Brick Code GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

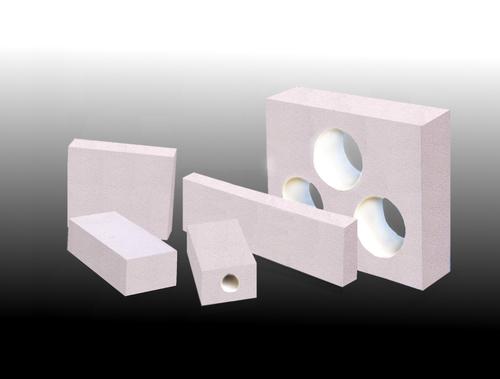

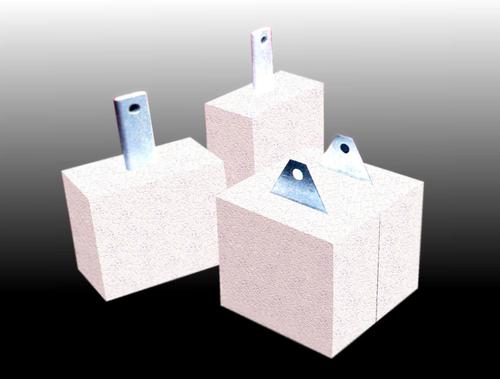

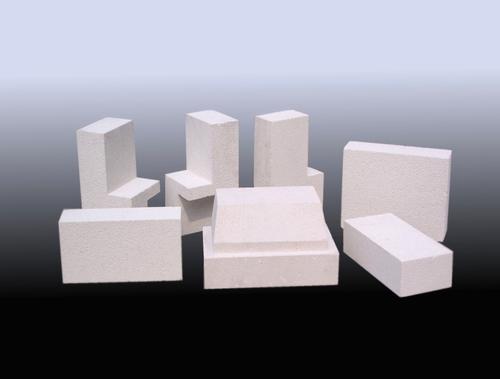

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: How do insulating fire bricks provide thermal insulation?

- The unique composition and structure of insulating fire bricks enable them to provide thermal insulation. These bricks utilize lightweight materials like clay, shale, and other minerals, which possess low thermal conductivity. As a result, they are not easily conductive of heat, serving as an effective barrier against heat transfer. Furthermore, insulating fire bricks are intentionally designed to have a porous structure. This design incorporates small air pockets within the bricks, effectively reducing the conduction of heat. These air pockets function as a barrier, effectively restricting the movement of heat from one side of the brick to the other. Moreover, insulating fire bricks possess a high melting point, rendering them suitable for high-temperature applications. This characteristic allows the bricks to endure extreme heat without undergoing deformation or breakdown, ensuring long-lasting thermal insulation. To summarize, the low thermal conductivity, porous structure, and high melting point of insulating fire bricks collectively contribute to their ability to provide thermal insulation. These attributes work in unison to minimize heat transfer, making them an excellent choice for situations requiring thermal insulation.

- Q: What is the difference between insulating fire bricks and regular fire bricks?

- Insulating fire bricks and regular fire bricks have different thermal properties and applications. Insulating fire bricks are specifically designed for their excellent insulation capabilities, making them perfect for situations where heat retention is crucial. These bricks have low thermal conductivity, which allows them to minimize heat transfer and maintain the desired temperature in enclosed spaces. As a result, they are commonly used in industries such as iron and steel, ceramics, glass, and petrochemicals, where efficient containment of high temperatures is necessary. On the other hand, regular fire bricks, also known as refractory bricks, focus more on enduring extreme heat and maintaining structural integrity in high-temperature environments. They are typically made from dense materials like clay or silica, which provide excellent resistance to heat, chemicals, and mechanical stress. Regular fire bricks are widely utilized in fireplaces, wood-burning stoves, kilns, and other heating appliances, as their dense composition ensures durability and resistance to thermal shock. To summarize, insulating fire bricks prioritize heat insulation, while regular fire bricks prioritize heat resistance and structural stability. The choice between the two depends on the specific requirements of the application. Insulating fire bricks are ideal for industries that require heat retention, while regular fire bricks are suitable for high-temperature environments where durability and resilience are crucial.

- Q: Are insulating fire bricks resistant to vibration or seismic activity?

- Yes, insulating fire bricks are typically resistant to vibration or seismic activity. They are designed to withstand high temperatures and provide insulation, which also makes them relatively stable and resistant to external forces such as vibrations or seismic activity.

- Q: How do insulating fire bricks compare to other insulation materials?

- Insulating fire bricks are highly effective insulation materials that offer several advantages over other insulation materials. First and foremost, insulating fire bricks have excellent thermal properties, meaning they can efficiently prevent the transfer of heat. They have a low thermal conductivity, which allows them to effectively insulate against high temperatures. This makes them ideal for use in applications where heat retention is crucial, such as furnaces, kilns, and fireplaces. Compared to other insulation materials like fiberglass or mineral wool, insulating fire bricks are much more durable and long-lasting. They can withstand extremely high temperatures without losing their insulating properties or structural integrity. This durability makes them a cost-effective choice since they require less frequent replacement. Another advantage of insulating fire bricks is their ability to resist chemical attack and wear. They are resistant to acids, alkalis, and other corrosive substances, making them suitable for applications involving harsh chemicals or environments. Furthermore, insulating fire bricks have a high compressive strength, allowing them to bear heavy loads without cracking or breaking. This makes them suitable for use in structural applications where weight-bearing capacity is essential. In terms of installation, insulating fire bricks are easy to work with. They can be cut, shaped, and installed using basic tools, allowing for customization and flexibility in different applications. They are also lightweight, which simplifies the installation process and reduces the overall weight of the structure. Overall, insulating fire bricks offer superior insulation properties, durability, resistance to chemicals, and ease of installation compared to other insulation materials. Their ability to withstand high temperatures, resist wear and tear, and provide long-lasting insulation make them an excellent choice in various industrial and domestic settings.

- Q: Can insulating fire bricks be used in industrial furnaces?

- Yes, insulating fire bricks can be used in industrial furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in various types of industrial furnaces.

- Q: Advantages and disadvantages of external formwork and self thermal insulation block

- Exterior wall sandwich thermal insulation technology, the exterior wall sandwich insulation is placed between the inside and outside wall panels of the outer wall, and the inner and outer wall can be made of concrete hollow block.Advantage:1) the inner wall film and insulation material form effective protection, the material selection of heat insulation material is not high, polystyrene, glass cotton and urea formaldehyde on-site pouring material can be used;2) the construction season and construction conditions are not very high, and it does not affect the winter construction. In Heilongjiang, Inner Mongolia, northern Gansu and other cold areas have been given some applications.Shortcoming:1) in non cold areas, this kind of wall is thicker than traditional wall;2) the inner and the outer wall pieces need to be connected by connecting pieces, and the structure is more complicated than the traditional wall;3) periphery structure of "bridge" more. In the earthquake zone, building circle beam and constructional column settings, "bridge" more efficiency of thermal insulation materials is still not fully play.4) outside the walls by the outdoor climate, the temperature difference between day and night and the large temperature difference between summer and winter, easy to cause the wall cracking and leakage of rainwater.

- Q: Are insulating fire bricks resistant to pests or rodents?

- Insulating fire bricks are not specifically designed or treated to be resistant to pests or rodents. While the dense nature of these bricks may make it more difficult for pests or rodents to chew through them compared to other materials, they are not completely immune to infestations. If you are concerned about pests or rodents, it is advisable to take additional measures such as sealing any gaps or cracks in the brickwork, ensuring proper ventilation, and implementing pest control methods as needed.

- Q: Are insulating fire bricks resistant to thermal conductivity?

- Insulating fire bricks possess the capability of withstanding thermal conductivity due to their design. These bricks are composed of materials that possess low thermal conductivity, such as lightweight refractory fibers or insulating substances like vermiculite or perlite. The main objective of insulating fire bricks is to offer thermal insulation and hinder the transfer of heat, making them a perfect fit for situations where temperature control is of utmost importance, like in kilns, furnaces, or fireplaces. By minimizing thermal conductivity, insulating fire bricks aid in preserving heat within the desired area and minimizing energy loss, thus proving to be an effective insulation choice in high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of regenerators?

- Yes, insulating fire bricks can be used in the construction of regenerators. These bricks are designed to have low thermal conductivity, which makes them suitable for applications that require heat insulation. Regenerators, which are used in various industries like glass manufacturing and metal refining, require materials that can withstand high temperatures and efficiently store and release heat. Insulating fire bricks can fulfill these requirements, making them a suitable choice for regenerator construction.

- Q: Can insulating fire bricks be used in the construction of brick kilns?

- Yes, insulating fire bricks can be used in the construction of brick kilns. These fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for lining the walls and floors of brick kilns. They help to retain heat, improve energy efficiency, and protect the kiln structure from thermal stress.

Send your message to us

Insulating Fire Brick - Refractory Insulating Fire Brick Code GJM23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords