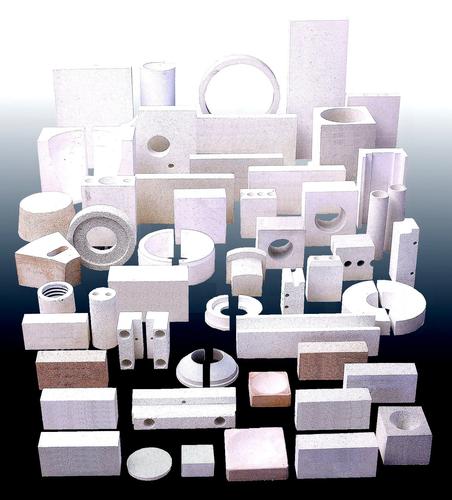

Insulating Fire Brick - High-Quality Insulation for Fire Safety

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Are insulating fire bricks suitable for use in glass melting furnaces?

- Insulating fire bricks can be suitable for use in glass melting furnaces, depending on the specific requirements of the furnace and the type of glass being melted. Insulating fire bricks are made from lightweight materials with low thermal conductivity, which makes them effective at retaining heat and reducing energy loss in the furnace. This can help improve the energy efficiency of the furnace and reduce operating costs. However, it is important to consider the temperature and atmosphere inside the glass melting furnace when choosing the type of insulating fire bricks. Glass melting furnaces operate at extremely high temperatures, often exceeding 1500°C (2732°F). Some insulating fire bricks may not be able to withstand such high temperatures and could degrade or even melt under these conditions. Additionally, the atmosphere inside the glass melting furnace can have an impact on the suitability of the insulating fire bricks. Some types of insulating fire bricks may react with certain gases or chemicals present in the furnace atmosphere, leading to degradation or contamination of the glass being melted. Therefore, it is crucial to select insulating fire bricks that are compatible with the specific atmosphere and conditions inside the glass melting furnace. In summary, insulating fire bricks can be suitable for use in glass melting furnaces, but careful consideration must be given to their temperature resistance and compatibility with the furnace atmosphere. Consulting with experts or suppliers who specialize in refractory materials for glass melting furnaces can help ensure the appropriate selection of insulating fire bricks for optimal furnace performance and glass quality.

- Q: Can insulating fire bricks be used in incinerators?

- Yes, insulating fire bricks can be used in incinerators. Insulating fire bricks are specially designed to provide excellent thermal insulation, making them ideal for applications where high temperatures need to be maintained. In incinerators, which operate at extremely high temperatures, insulating fire bricks can help to reduce heat loss and improve the overall energy efficiency of the system. Additionally, these bricks have good resistance to thermal shock, which is crucial in incinerators where rapid temperature changes occur. Therefore, using insulating fire bricks in incinerators can help to enhance their performance and longevity.

- Q: Do insulating fire bricks have a high fireproof rating?

- Indeed, insulating fire bricks possess a remarkable fireproof rating. These bricks have been specifically engineered to endure exceedingly high temperatures and offer exceptional insulation against the transfer of heat. They are crafted using specialized refractory materials with limited thermal conductivity, thereby aiding in the retention of heat and preventing its escape from the system. Insulating fire bricks are capable of withstanding temperatures ranging from 2300°F to 3100°F (1260°C to 1700°C), rendering them ideal for utilization in furnaces, kilns, fireplaces, and other applications involving elevated temperatures. Their elevated fireproof rating guarantees their ability to effectively safeguard structures and equipment from the intense heat and flames, enabling secure and efficient operations across diverse industries.

- Q: How long do insulating fire bricks typically last?

- Insulating fire bricks typically last for several years, with an average lifespan of 10 to 20 years.

- Q: Can insulating fire bricks be used in the construction of hot blast stoves?

- Indeed, it is possible to utilize insulating fire bricks in the fabrication of hot blast stoves. These bricks are specifically engineered to possess a low thermal conductivity, rendering them highly efficient in diminishing heat dissipation. In order to ensure optimal functionality, hot blast stoves necessitate the maintenance of elevated temperatures, a goal that can be accomplished through the utilization of insulating fire bricks, which effectively restrict heat transfer to the stove's external surface. Furthermore, these bricks exhibit commendable insulation properties, enabling energy conservation and enhancing the overall efficiency of the stove. Moreover, it is worth noting that insulating fire bricks are resistant to thermal shock, a crucial attribute in hot blast stove applications where frequent temperature fluctuations are common.

- Q: Are insulating fire bricks resistant to high-velocity gases?

- In general, insulating fire bricks possess resistance to high-velocity gases. These bricks are specifically designed with high thermal resistance and low thermal conductivity, rendering them suitable for situations where exposure to elevated temperatures and gases is prevalent. Without experiencing any damage or compromise, they are capable of enduring the force and speed of gases. In the realm of industrial furnaces, kilns, and other high-temperature settings, insulating fire bricks find common application, as they fulfill the dual role of insulation and safeguard against high-velocity gases.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- In the realm of copper smelting furnaces, the utilization of insulating fire bricks is indeed possible. These fire bricks have been specifically engineered to endure high temperatures and offer remarkable insulation, rendering them an ideal choice for furnace usage. Composed of materials capable of withstanding the intense heat generated during the smelting process, these bricks are proficient in both retaining and reflecting heat back into the furnace. This aids in the maintenance of the desired temperature and enhances energy efficiency. Moreover, the inclusion of insulating fire bricks can curtail heat loss, thereby resulting in swifter and more efficient copper smelting. For this reason, the incorporation of insulating fire bricks into copper smelting furnaces has become a widespread practice within the industry.

- Q: Can insulating fire bricks be used for insulation in foundries?

- Insulating fire bricks have the capability to be utilized for insulation purposes in foundries. These bricks are specially constructed to possess a high level of thermal resistance and a low level of thermal conductivity, rendering them exceptionally suitable for scenarios that necessitate insulation. In the context of foundries, where elevated temperatures are present, insulating fire bricks can be employed to line the walls, floors, and roofs, thus diminishing heat loss and enhancing energy efficiency. Furthermore, they contribute to maintaining a consistent temperature within the foundry, thereby ensuring uniform dispersion of heat while preventing heat loss to the surrounding environment. Moreover, owing to their lightweight nature and easy installation process, insulating fire bricks emerge as a pragmatic choice for insulation in foundries.

- Q: What is the weight of insulating fire bricks?

- The size and composition of insulating fire bricks can cause their weight to differ. Typically, each brick weighs around 3.5 to 5 pounds (1.6 to 2.3 kilograms). Nonetheless, it is crucial to consider that this weight may change depending on the manufacturer and the brick's density. To obtain precise weight information for the insulating fire bricks you desire, it is advisable to refer to the product specifications or seek guidance from the supplier.

- Q: Can insulating fire bricks be used in residential applications, such as fireplaces or ovens?

- Insulating fire bricks can indeed be used in residential applications such as fireplaces or ovens. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight materials such as clay or alumina, which have low thermal conductivity. This helps to keep the heat inside the fireplace or oven, making it more efficient and reducing energy consumption. Insulating fire bricks also have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Additionally, these bricks are non-combustible, ensuring they can withstand the high temperatures generated in fireplaces or ovens without posing a fire hazard. Therefore, insulating fire bricks are a suitable choice for residential applications where high temperatures and thermal insulation are required.

Send your message to us

Insulating Fire Brick - High-Quality Insulation for Fire Safety

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords