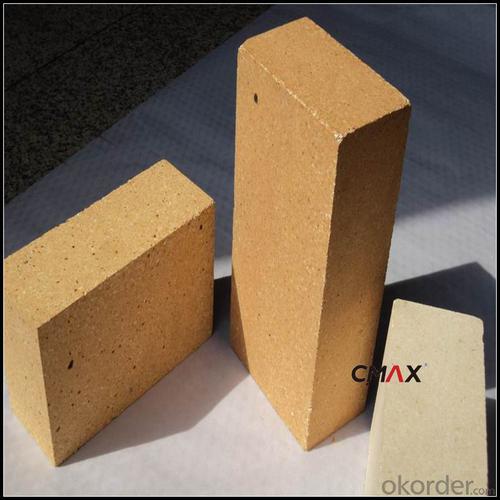

Insulating Fire Brick for Standard Size Insulation Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Weight Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

The thermal insulation brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

Light Weight Insulating Brick Features

1. Containing a large number of closed pores

2. Have a lightweight high temperature

3. Good insulation properties

4. Refiring small contraction

5. Excellent thermal shock resistance

6. Strong resistance to the corrosive gas and slag.

Light Weight Insulating Brick Application

The thermal insulation brick can be in direct contact with the flame, to apply to the cracking furnace, hot stove, furnace, tunnel kiln, push board kiln, crucible furnace and electric furnace, electric kilns lined widely used in metallurgy, refractories, light industry, chemical industry, ceramics, glass, electronics and other industries. Dimensions of the product, the physical and chemical indicators, service life have reached or exceeded the level of similar products at domestic and abroad.

Light Weight Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Do insulating fire bricks have a low density?

- Yes, insulating fire bricks typically have a low density compared to other types of bricks.

- Q: Are insulating fire bricks suitable for insulation in walls?

- Yes, insulating fire bricks are suitable for insulation in walls. They are designed to have excellent thermal insulation properties, high heat resistance, and low thermal conductivity. These characteristics make them effective at reducing heat transfer and providing insulation in wall systems.

- Q: Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks do require maintenance. While they are known for their durability and ability to withstand high temperatures, regular maintenance is necessary to ensure their optimal performance and longevity. One key aspect of maintenance is periodic cleaning. Over time, insulating fire bricks can accumulate dust, soot, and other debris, which can affect their insulating properties. Therefore, it is recommended to clean the bricks regularly to remove any build-up. This can be done using a soft brush or a mild cleaning solution. Another important aspect of maintenance is checking for any cracks or damages. Inspecting the bricks for any signs of wear and tear is crucial to identify and address any issues before they worsen. Cracks or damages can compromise the bricks' insulation and stability, so they should be repaired or replaced as needed. Furthermore, it is important to monitor the condition of the mortar or refractory cement used to hold the insulating fire bricks together. Over time, the mortar can deteriorate due to exposure to heat and other elements. Regularly inspecting and repairing any damaged mortar helps to maintain the structural integrity of the fire bricks. In addition to these maintenance tasks, it is essential to follow the manufacturer's instructions and recommendations for the specific type of insulating fire bricks used. This may include guidelines for installation, temperature limits, and any other specific care instructions. Overall, while insulating fire bricks are durable, regular maintenance is necessary to ensure their optimal performance and prolong their lifespan. Proper cleaning, inspecting for damage, and following manufacturer's guidelines are key components of maintaining insulating fire bricks.

- Q: Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic tile kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. They have low thermal conductivity, which means they help to retain heat within the kiln and prevent it from escaping, resulting in more efficient and effective firing of ceramic tiles. Additionally, their lightweight nature makes them easy to handle and install in the kiln structure. Overall, using insulating fire bricks in the construction of ceramic tile kilns can help improve energy efficiency, reduce heat loss, and ensure consistent and controlled firing temperatures.

- Q: Do insulating fire bricks have a high fire resistance rating?

- Yes, insulating fire bricks have a high fire resistance rating. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent insulation against heat transfer. They are made from high-purity refractory materials, such as alumina and silica, which have a high melting point and can withstand extreme heat. These bricks are capable of withstanding temperatures of up to 3000°F (1650°C) and have a thermal conductivity that is much lower than regular bricks or other materials. This makes them ideal for use in applications where high fire resistance is required, such as in industrial furnaces, kilns, fireplaces, and chimneys. Additionally, their insulating properties help to reduce heat loss, making them energy-efficient and cost-effective.

- Q: Are insulating fire bricks resistant to cracking?

- Yes, insulating fire bricks are designed to be highly resistant to cracking. They are manufactured to withstand high temperatures and thermal shocks, ensuring their durability and preventing cracks from developing.

- Q: Can insulating fire bricks be used in heat exchangers?

- Yes, insulating fire bricks can be used in heat exchangers. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them suitable for use in high-temperature applications such as heat exchangers. These bricks are made from lightweight materials and have low thermal conductivity, allowing them to effectively reduce heat loss or gain in the heat exchanger. Additionally, insulating fire bricks have high resistance to thermal shock and can withstand extreme temperatures, making them a reliable choice for heat exchanger applications. Overall, using insulating fire bricks in heat exchangers can contribute to improved energy efficiency and performance.

- Q: What is the bulk density of insulating bricks?

- National classification standard: water absorption rate of ceramic tile is less than or equal to 0.5%;

- Q: Are insulating fire bricks resistant to insects and rodents?

- Yes, insulating fire bricks are generally resistant to insects and rodents due to their dense and solid construction, which makes it difficult for pests to penetrate or damage them.

- Q: Can insulating fire bricks be used for kiln furniture?

- Indeed, kiln furniture can be fashioned from insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are frequently employed in industrial kilns and furnaces. Their exceptional thermal insulation characteristics render them perfect for crafting kiln furniture like shelves, posts, and supports. The insulating attributes of these bricks aid in the uniform dispersion of heat throughout the kiln, guaranteeing consistent heating of the items being fired. Furthermore, insulating fire bricks possess a lightweight composition and are effortlessly manageable, thereby making them a convenient selection for kiln furniture.

Send your message to us

Insulating Fire Brick for Standard Size Insulation Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords