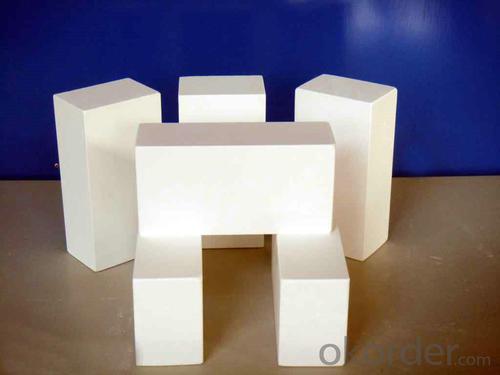

Insulating Fire Brick - Lightweight Insulation Refractory Clay for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of drying ovens?

- Indeed, the utilization of insulating fire bricks is feasible for the fabrication of drying ovens. These bricks possess a design that enables them to exhibit minimal thermal conductivity. Consequently, they possess the ability to proficiently retain heat and hinder heat dissipation. This characteristic renders them a prime material for the construction of drying ovens, as they can effectively sustain a consistent and regulated temperature within the oven. Moreover, insulating fire bricks demonstrate resistance to elevated temperatures, thereby establishing their suitability for deployment in drying ovens that necessitate such conditions.

- Q: Can insulating fire bricks be used for high-temperature insulation?

- Yes, insulating fire bricks can be used for high-temperature insulation. These bricks are specially designed to withstand extreme temperatures, making them suitable for insulation in applications such as kilns, furnaces, and fireplaces. They have excellent thermal conductivity and can effectively reduce heat loss, making them an ideal choice for high-temperature insulation needs.

- Q: Can insulating fire bricks be used for insulation in residential walls?

- Insulating fire bricks are primarily designed for high-temperature applications, such as in kilns or furnaces. While they do provide excellent insulation properties, they are not typically recommended for use in residential walls. The reason is that insulating fire bricks may not meet the specific building codes and regulations required for residential construction. Additionally, there are other insulation materials available that are better suited for residential walls, such as fiberglass or foam insulation, which are more cost-effective and easier to install.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Insulating fire bricks prove to be suitable for ladles and tundishes as they are specifically designed to offer high-temperature insulation and thermal stability. These bricks are essential in applications where heat retention plays a pivotal role. Ladles and tundishes are extensively utilized in the steel and foundry sectors for the transportation and pouring of molten metal. By utilizing insulating fire bricks in these vessels, one can effectively minimize heat loss and maintain the desired temperature of the metal. Moreover, these bricks exhibit resilience towards thermal shock and chemical corrosion, which are common obstacles in such extreme temperature environments. Consequently, the utilization of insulating fire bricks in ladles and tundishes ultimately enhances energy efficiency, reduces heat loss, and improves the overall performance and lifespan of these vital pieces of equipment in the metal processing industry.

- Q: Are insulating fire bricks resistant to ultraviolet radiation?

- No, insulating fire bricks are not resistant to ultraviolet radiation.

- Q: Can insulating fire bricks be used in chimney construction?

- Yes, insulating fire bricks can be used in chimney construction. These bricks have high heat resistance and low thermal conductivity, making them suitable for lining chimneys and other high-temperature applications. They help to insulate the chimney and prevent excessive heat transfer, reducing the risk of structural damage and improving energy efficiency.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining furnaces and kilns used in lime production. They can help maintain the desired temperature, conserve energy, and improve the efficiency of the lime production process.

- Q: Can insulating fire bricks be used in rotary kilns?

- Yes, insulating fire bricks can be used in rotary kilns. Insulating fire bricks are designed to have low thermal conductivity, which helps to reduce heat loss and improve energy efficiency in high-temperature applications like rotary kilns. Additionally, these bricks are lightweight and have good thermal shock resistance, making them suitable for the harsh and dynamic conditions within a rotary kiln.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Yes, it is possible to cut insulating fire bricks to fit custom shapes. These bricks can be easily cut using a saw or other cutting tools to achieve the desired shape and size for specific applications.

- Q: How do insulating fire bricks affect the overall weight of a structure?

- Insulating fire bricks can significantly affect the overall weight of a structure due to their lightweight nature. As the name suggests, these bricks are designed to have low density and high thermal resistance properties. Unlike traditional bricks or concrete blocks, insulating fire bricks are made from lightweight materials such as clay, silica, and aluminum oxide. Due to their reduced weight, using insulating fire bricks in construction can help reduce the overall load on a structure. This can be particularly advantageous in cases where weight restrictions or limitations are a concern, such as in high-rise buildings or areas with poor soil conditions. The lightweight nature of insulating fire bricks also allows for easier transportation, handling, and installation, making construction processes more efficient and cost-effective. Additionally, the reduced weight can minimize the need for heavy machinery or specialized equipment during the construction phase. Moreover, the use of insulating fire bricks can also have a positive impact on the overall energy efficiency of a structure. Their high thermal resistance properties help to minimize heat transfer, making the building more thermally efficient. This can lead to lower energy consumption for heating or cooling, resulting in reduced utility bills and a smaller carbon footprint. In summary, insulating fire bricks can significantly impact the overall weight of a structure by providing a lightweight alternative to traditional bricks or concrete blocks. Their low density not only reduces the load on the structure but also offers benefits such as easier handling and installation. Furthermore, their high thermal resistance properties contribute to improved energy efficiency.

Send your message to us

Insulating Fire Brick - Lightweight Insulation Refractory Clay for Industrial Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords