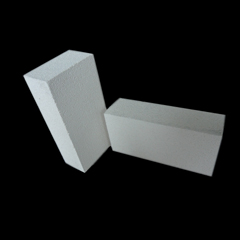

High-Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description:

lightweight mullite brick is made from high-grade and high purity refractory powders and materials.During the process of production,organic and multiple filling materials are injected according to required proportion.The brick is compressed in vacuum and sintered under high temperature. Category:

LYJM-23A LYJM-23B LYJM-23C

LYJM-26A LYJM-26B LYJM-26C

LYJM-28A LYJM-28B

LYJM-30A LYJM-30B

Features:

Low thermal conductivity and capacity

High purity,low content of impurity

High thermal resistance and could contact fire directly

High strength and resistant to thermal shock

Accurate measurement and incised optionally

Typical applications:

Lining and back lining of various furnaces in the industry of metallurgy,petrochemical,ceramics,machinery and building materials.

For instance:the Cracking Furnace,Conversion Furnace,heating equipment,refining equipment,Hot Blast Stove,Heating Furnace,Even-heating Furnace,Heat-processing Furnace,Resistance Furnace,Tunnel Kiln,Shuttle Kiln,Bell-cover Kiln,Glass-pool Kiln,etc

- Q: Do insulating fire bricks require any curing or drying time?

- No, insulating fire bricks do not require any curing or drying time. These bricks are manufactured using high-temperature processes, which results in a product that is already fully cured and dried. This means that they can be used immediately after installation without the need for additional curing or drying time.

- Q: Can insulating fire bricks be used in ceramic kilns?

- Yes, insulating fire bricks can be used in ceramic kilns. Insulating fire bricks are designed to have low thermal conductivity, which means they are able to retain heat more effectively. This makes them an ideal choice for lining the walls of a kiln, as they help to conserve and distribute heat more evenly throughout the kiln chamber. Additionally, insulating fire bricks are lightweight and have a high resistance to thermal shock, which makes them durable and able to withstand the high temperatures typically reached in ceramic kilns.

- Q: Can insulating fire bricks be used in metal melting furnaces?

- Indeed, metal melting furnaces can utilize insulating fire bricks. Specifically tailored to endure high temperatures and offer exceptional insulation, these bricks prove to be an optimal selection for applications such as metal melting furnaces. These bricks possess a low thermal conductivity, which aids in heat preservation and diminishes energy usage. Furthermore, insulating fire bricks are lightweight, long-lasting, and capable of withstanding thermal shock, rendering them a fitting choice for the severe conditions experienced in metal melting furnaces.

- Q: Are insulating fire bricks resistant to thermal bridging?

- Insulating fire bricks possess resistance against thermal bridging. Thermal bridging arises when a material allows heat to flow directly, thereby bypassing the insulation. Insulating fire bricks counteract this issue by minimizing thermal conductivity, which renders them ineffective at conducting heat. This characteristic aids in maintaining a uniform temperature on either side of the brick, thereby preventing thermal bridging and enhancing the overall insulation performance.

- Q: Are insulating fire bricks resistant to weathering?

- Yes, insulating fire bricks are resistant to weathering.

- Q: Are insulating fire bricks suitable for use in steel mills?

- Yes, insulating fire bricks are suitable for use in steel mills. Insulating fire bricks are made from lightweight materials that have high insulating properties, allowing them to withstand high temperatures and provide effective insulation. In steel mills, where extremely high temperatures are generated during the steelmaking process, insulating fire bricks are used to line furnaces, kilns, and other high-temperature applications. These bricks help to reduce heat loss, improve energy efficiency, and protect the steel mill equipment from excessive heat. Additionally, insulating fire bricks have good thermal shock resistance, which is essential in steel mills where rapid temperature changes occur. Overall, the use of insulating fire bricks in steel mills is a reliable and effective solution for maintaining high-temperature environments and optimizing the steelmaking process.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Insulating fire bricks are specifically designed for high-temperature applications and are often used in furnaces, kilns, and other industrial settings. While they do possess excellent insulating properties, they may not be the best choice for chimneys and flues in residential or commercial buildings. The main reason for this is that insulating fire bricks are not as durable and heat-resistant as other materials specifically designed for chimney and flue construction. They may crack or break when exposed to the extreme heat and rapid temperature changes that occur in chimneys. Additionally, these bricks are not typically designed to withstand the corrosive effects of flue gases, which can lead to their degradation over time. When it comes to chimneys and flues, it is generally recommended to use materials such as clay flue liners, stainless steel, or refractory bricks that are specifically manufactured for these applications. These materials are better suited to handle the high temperatures, corrosive gases, and rapid thermal expansion and contraction that occur in chimneys. It is important to consult with a professional chimney or flue specialist who can advise on the appropriate materials to use based on the specific requirements and conditions of your chimney or flue system.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Yes, insulating fire bricks can be used in the construction of thermal oxidizers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for applications such as thermal oxidizers, which require efficient heat transfer and containment of high temperatures.

- Q: Are there any safety precautions to consider when using insulating fire bricks?

- Yes, there are safety precautions to consider when using insulating fire bricks. Firstly, it is important to wear appropriate personal protective equipment, such as gloves and safety goggles, to protect against potential injuries. Additionally, due to the high temperatures involved, it is crucial to handle the bricks with care to avoid burns or related accidents. Adequate ventilation should be ensured to prevent the buildup of harmful gases and fumes. Lastly, it is essential to follow the manufacturer's instructions and guidelines for proper installation and usage to minimize any potential risks.

- Q: Are insulating fire bricks resistant to sulfur dioxide?

- In general, insulating fire bricks do not possess resistance against sulfur dioxide. This highly corrosive gas can undergo reactions with the components of insulating fire bricks, resulting in their deterioration and diminished efficiency. Therefore, it is crucial to utilize refractory materials that are specifically engineered to endure exposure to sulfur dioxide, whenever such a requirement exists for the intended application.

Send your message to us

High-Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords