Insulating Fire Brick - Refractory Mullite GJM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

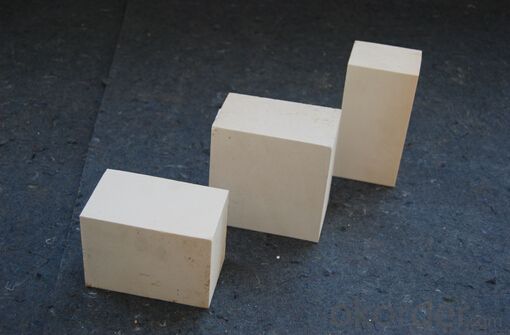

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to sulfates?

- Insulating fire bricks exhibit resistance to sulfates in general. These bricks consist of high-alumina or silica materials, which possess favorable chemical resistance properties. Sulfates, a type of chemical compound, can undergo reactions with certain materials, leading to deterioration. However, insulating fire bricks are specifically engineered to endure high temperatures and harsh chemical environments, including exposure to sulfates. They commonly find applications in furnaces, kilns, and incinerators where they might come into contact with sulfates. Nevertheless, it is crucial to consider the precise composition and quality of the insulating fire bricks, along with the concentration and duration of sulfate exposure, in order to guarantee their long-lasting performance and durability.

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Yes, insulating fire bricks can be used in the construction of smelting ovens. They have excellent thermal insulation properties, high temperature resistance, and can withstand the intense heat generated during the smelting process. This makes them an ideal choice for lining the walls and floors of smelting ovens to maintain high temperatures and minimize heat loss.

- Q: Can insulating fire bricks be used in refractory cement?

- Yes, insulating fire bricks can be used in refractory cement. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, while refractory cement is used to bind and seal refractory materials. By using insulating fire bricks in refractory cement, it can enhance the overall insulation properties and improve the performance of the cement in high-temperature applications.

- Q: Are insulating fire bricks resistant to carbon monoxide attack?

- Insulating fire bricks have a general resistance to carbon monoxide attack. They are made from materials that can withstand high temperatures and chemical corrosion, including carbon monoxide. These bricks are commonly used in environments where high temperatures and exposure to gases like carbon monoxide are frequent, such as furnaces, kilns, and fireplaces. The composition of the bricks allows them to endure long periods of exposure to carbon monoxide without deteriorating or reacting with the gas. However, it is important to remember that continuous exposure to extremely high levels of carbon monoxide can eventually harm any material, including insulating fire bricks. Therefore, it is still crucial to ensure proper ventilation and safety precautions when dealing with carbon monoxide in any situation.

- Q: Can insulating fire bricks be used in ladles?

- Yes, insulating fire bricks can be used in ladles.

- Q: Can insulating fire bricks be used in the construction of BBQ pits?

- Yes, insulating fire bricks can be used in the construction of BBQ pits. Insulating fire bricks are designed to withstand high temperatures and have excellent heat resistance properties, making them ideal for use in BBQ pits. These bricks help trap and distribute heat evenly, resulting in more efficient cooking and a better BBQ experience. Additionally, insulating fire bricks also help to reduce heat loss, ensuring that the BBQ pit retains and maintains heat for a longer period. Overall, using insulating fire bricks in the construction of BBQ pits can greatly enhance the performance and longevity of the pit.

- Q: What is the compressive strength of insulating fire bricks?

- The compressive strength of insulating fire bricks typically ranges from 1 MPa (megapascal) to 15 MPa, depending on the specific composition and manufacturing process of the bricks.

- Q: Are insulating fire bricks resistant to phosphorus pentoxide?

- Insulating fire bricks are generally not resistant to phosphorus pentoxide. Phosphorus pentoxide is a highly reactive compound that can corrode and degrade most materials, including insulating fire bricks. It is important to consider alternative materials or protective coatings if there is a need for resistance to phosphorus pentoxide in a specific application.

- Q: Can insulating fire bricks be used for insulation in power plants?

- Insulating fire bricks have proven themselves to be effective for insulation purposes in power plants. These bricks are specifically designed to possess exceptional thermal insulation properties, making them highly suitable for applications involving high temperatures. They can endure extreme temperatures and effectively insulate power plant operations, thus preventing heat loss and enhancing energy efficiency. In power plants, insulating fire bricks find extensive usage in various areas, including furnaces, boilers, kilns, and chimneys. They can be utilized to line the walls, floors, and roofs of these structures, aiming to minimize heat transfer and maintain optimal temperatures within the equipment. The utilization of insulating fire bricks in power plants offers numerous benefits. These bricks aid in reducing heat loss, enhancing combustion efficiency, and alleviating thermal stress on the equipment. They create a barrier against heat transfer, thereby conserving energy and minimizing operational expenses. Moreover, their insulation properties contribute to a safer working environment for power plant personnel. Nevertheless, it is important to exercise caution when selecting insulating fire bricks for power plant insulation. The specific requirements and conditions of the power plant should be carefully considered. Factors such as operating temperature, exposure to chemicals, and mechanical stress should be taken into account to ensure that the bricks are capable of withstanding harsh conditions and delivering long-lasting insulation performance.

- Q: What is the thermal expansion of insulating fire bricks?

- Insulating fire bricks undergo changes in dimensions or volume when subjected to temperature variations. These bricks are designed to possess low thermal conductivity and high heat resistance, making them ideal for situations that require insulation and heat containment. Compared to other fire brick varieties, insulating fire bricks exhibit relatively minimal thermal expansion. This is attributed to their composition and manufacturing process, which typically involve lightweight materials like clay, alumina, and silica mixed with organic additives. The low thermal expansion of insulating fire bricks allows them to maintain their shape and structural integrity, even under high temperature conditions. This characteristic is especially crucial in applications that involve thermal cycling, such as furnaces, kilns, and thermal insulation systems. To determine the precise thermal expansion coefficient of a particular brand or type of insulating fire brick, it is necessary to take into account its specific composition and manufacturing process. However, in general, insulating fire bricks possess a lower thermal expansion coefficient compared to conventional fire bricks. This ensures their stability and durability in environments with elevated temperatures.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords