Refractory Mullite Insulating Fire Brick GJM 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Top insulation ceramic fiber blanket

General information of ceramic fiber blanket

Cmax ceramic fiber blanket is made of high quality kaolin clay, centrifugal high purity alumina and silica or blowing process. It's no asbestos. Double side acupuncture for easy installation provides a lot of tension or strength of the blanket.

Products are divided into standard, high pressure, HA and Hz, respectively, corresponding to the highest service temperature of 1000, 1100, 1200, and 1350

Characteristics of ceramic fiber blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Thermal shock toughness

High tensile strength

Application of ceramic fiber blanket

Refractory fiber lining for petrochemical process heating furnace

Heat treatment furnace or intermittent (shuttle) kiln heat surface lining

General oven standby insulation

Heat sealing or kiln kiln car door

Electrical insulation

Ceramic fiber blanket

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

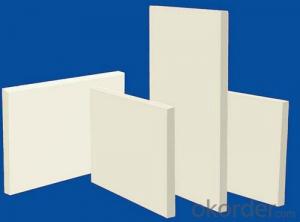

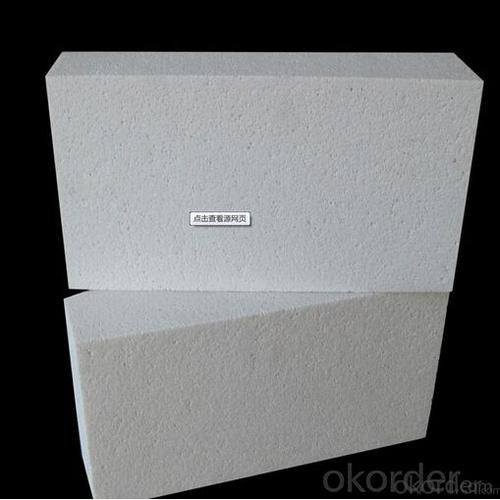

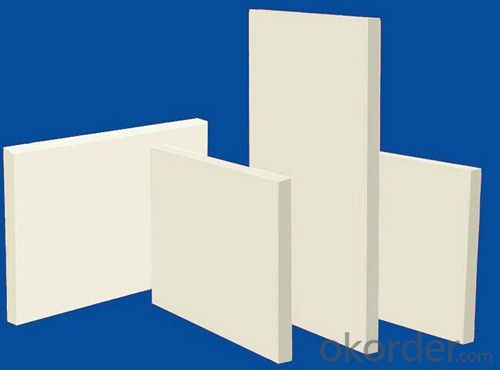

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Do insulating fire bricks require any curing or drying time?

- Absolutely not! Insulating fire bricks do not need any curing or drying time whatsoever. These bricks are produced through high-temperature methods, resulting in a completely cured and dried product. Consequently, they can be utilized right after installation without any requirement for extra curing or drying time.

- Q: What is the price of refractory bricks?

- Insulating brick is a refractory brick often used in kilns to reduce the heat loss of kilnsSo as to ensure the practical efficiency of kiln and bring more benefits.There are many kinds of thermal insulation bricks, and there are many refractory manufacturersAs to how much bricks should be paid, a detailed consultation should be made to the refractory bricks manufacturerHave some understanding of the properties, technologies, raw materials and so on, and make a decisionDifferent types of insulation brick prices are different, the price is relatively cheap, lightweight clay insulation brick 1The market price is 1.3 yuan a pieceThe price of mullite heat preservation brick 0.8, the market price of 4.62 yuan a pieceDepending on the area, the price of insulating bricks will fluctuate somewhat

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Yes, insulating fire bricks are suitable for use in coke ovens. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in coke ovens where extreme heat is generated during the coking process. They help to maintain the desired temperature inside the oven and prevent heat loss, resulting in improved energy efficiency and reduced fuel consumption. Additionally, insulating fire bricks have good resistance to chemical reactions and thermal shock, which further enhances their suitability for use in coke ovens.

- Q: Can insulating fire bricks be used in fireplaces?

- Yes, insulating fire bricks can be used in fireplaces. They are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the inside of fireplaces.

- Q: Are insulating fire bricks suitable for use in the construction of incinerators?

- Yes, insulating fire bricks are suitable for use in the construction of incinerators. Insulating fire bricks have excellent thermal insulation properties, allowing them to withstand high temperatures and efficiently retain heat. This makes them ideal for lining the walls and floors of incinerators, as they help to contain and direct heat, ensuring proper combustion while reducing heat loss. Additionally, insulating fire bricks are resistant to chemical attacks and can withstand the corrosive environment found in incinerators, making them a reliable choice for this application.

- Q: Can insulating fire bricks be used for insulation in hot blast stoves?

- Insulating fire bricks are suitable for insulation in hot blast stoves due to their ability to withstand high temperatures and provide excellent thermal insulation. These bricks are constructed using lightweight materials with low thermal conductivity, enabling them to effectively retain heat and prevent heat transfer to the surrounding environment. By incorporating insulating fire bricks in hot blast stoves, the internal temperatures can be preserved at high levels while minimizing heat loss. As a result, the stove's energy efficiency is enhanced, and the structure is safeguarded from excessive heat. Consequently, the practice of using insulating fire bricks for insulation in hot blast stoves is widely adopted and proven to be effective.

- Q: Do insulating fire bricks have a low thermal expansion rate?

- Yes, insulating fire bricks generally have a low thermal expansion rate. These bricks are designed to withstand high temperatures and thermal shocks, and one of their key properties is their ability to maintain their shape and dimensions under extreme heat conditions. Insulating fire bricks are made from materials that have a low coefficient of thermal expansion, meaning they expand and contract minimally when exposed to changes in temperature. This low thermal expansion rate ensures that the bricks remain stable and do not crack or break due to thermal stress. Additionally, the low thermal expansion rate of insulating fire bricks allows for better insulation performance, as it minimizes the gaps that can form between the bricks when they expand and contract, reducing heat loss and increasing energy efficiency.

- Q: Can insulating fire bricks be used in the construction of refractory coatings?

- Yes, insulating fire bricks can be used in the construction of refractory coatings. Insulating fire bricks are designed to have low thermal conductivity, making them suitable for insulating applications. When used as a component in refractory coatings, they can help to enhance the insulation properties and provide thermal protection.

- Q: Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat within the oven. This property is especially important in drying ovens as it helps to maintain a consistent and even temperature throughout the drying process. Additionally, insulating fire bricks have high resistance to thermal shock, meaning they can withstand the rapid temperature changes that may occur during the heating and cooling cycles of the oven. This durability ensures that the bricks will not crack or break under extreme temperature conditions. Furthermore, insulating fire bricks are lightweight and easy to handle, making them convenient for installation in drying ovens. Overall, these bricks provide excellent insulation and thermal stability, making them a suitable choice for the construction of drying ovens.

- Q: What are the different sizes and shapes available for insulating fire bricks?

- Insulating fire bricks come in various sizes and shapes to meet different insulation needs. Common sizes include standard, medium, and large, with dimensions ranging from 9" x 4.5" x 2.5" to 12" x 12" x 2". As for shapes, they are available in rectangular, square, and custom shapes like arches and wedges. The specific size and shape of the insulating fire brick depend on the requirements of the application and the manufacturer's offerings.

Send your message to us

Refractory Mullite Insulating Fire Brick GJM 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords