Standard Aluminum Profiles - Aluminum Sheet Plate Stocks Warehouse Cold Rolled Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

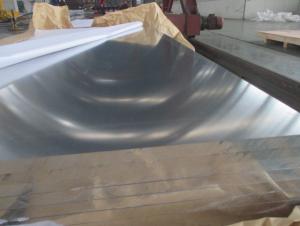

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do aluminum profiles contribute to LEED certification?

- LEED certification can be achieved through various means with the use of aluminum profiles. Firstly, aluminum is a sustainable material that can be easily recycled without compromising its quality. Incorporating aluminum profiles in construction projects helps reduce the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's objective of minimizing the environmental impact of buildings. Furthermore, aluminum profiles possess the qualities of being lightweight and durable, making transportation and installation efficient. This aspect contributes to earning LEED points in the Sustainable Sites category, which emphasizes the use of materials and techniques that have minimal impact on ecosystems and reduce pollution during construction. Moreover, aluminum profiles can enhance energy efficiency in buildings. By incorporating features like thermal breaks and insulation, aluminum profiles prevent heat transfer and reduce energy consumption for heating or cooling. This aspect contributes to earning LEED points in the Energy and Atmosphere category, which advocates for the use of energy-efficient systems and materials. Additionally, aluminum profiles are corrosion-resistant and require minimal maintenance throughout their lifespan. This durability contributes to earning LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials to minimize waste and the need for replacement. In conclusion, aluminum profiles play a vital role in achieving LEED certification as they promote sustainability, reduce environmental impacts, improve energy efficiency, and enhance building durability. By considering the incorporation of aluminum profiles in construction projects, architects and builders can earn LEED credits and contribute to a more sustainable future.

- Q: Can aluminum profiles be used for greenhouse construction?

- Yes, aluminum profiles can be used for greenhouse construction. Aluminum is a popular choice for greenhouse frames due to its durability, lightweight nature, and resistance to corrosion. It is also easy to work with, allowing for flexibility in design and construction. Aluminum profiles provide a strong and stable structure that can withstand harsh weather conditions and provide long-term support for the greenhouse covering materials. Additionally, aluminum frames require minimal maintenance and have a longer lifespan compared to other materials, making them a cost-effective option for greenhouse construction.

- Q: This question asks for methods to prevent corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion of aluminum profiles during installation, follow these steps: 1. Use stainless steel fasteners and avoid galvanized or carbon steel screws which can cause galvanic corrosion. 2. Keep the aluminum profiles clean and dry during installation to avoid contact with moisture which can initiate corrosion. 3. Apply a protective coating or sealant to the profiles, especially at cut edges where the protective oxide layer may be compromised. 4. Store aluminum profiles in a dry, cool place before installation to prevent moisture absorption. 5. Regularly inspect and maintain the profiles to identify and address any signs of corrosion early. By adhering to these practices, you can significantly reduce the risk of corrosion on aluminum profiles during installation.</p>

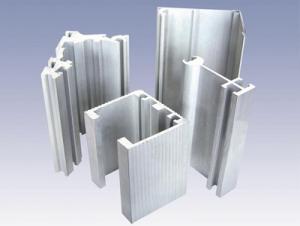

- Q: What is aluminum profile?

- Aluminum bars: aluminum bars are obtained by hot extrusion and extrusion so as to obtain aluminum materials of different cross section. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoresis coating, fluorine carbon spraying, powder spraying, grain transfer and other processes. Aluminum profile features: 1) corrosion resistance; aluminum profile density is only 2.7g/cm3, about steel, copper or brass density (7.83g/, cm3, 8.93g/, cm3), 1/3. Aluminum can show excellent corrosion resistance in most ambient conditions, including air, water (or brine), petrochemical, and many chemical systems. 2) conductivity; aluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper. 3) thermal conductivity; the thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as the cylinder head and radiator of automobiles.

- Q: Identify the key elements to evaluate when choosing aluminum profiles for a particular project.

- <p>When selecting aluminum profiles for a specific project, consider the following factors: 1) Load-bearing capacity, ensuring the profile can support the intended weight and stress; 2) Dimensional stability, to maintain structural integrity over time; 3) Corrosion resistance, especially for outdoor or humid environments; 4) Aesthetics, matching the profile's appearance with the project's design; 5) Cost-effectiveness, balancing quality with budget constraints; 6) Availability of the profile, considering lead times and supply chain reliability; 7) Ease of fabrication and assembly, which can affect construction time and labor costs; 8) Thermal properties, important for energy efficiency in buildings; 9) Compliance with industry standards and regulations; 10) Customizability, for projects with unique specifications or design requirements.</p>

- Q: Can aluminum profiles be used in corrosive environments?

- Yes, aluminum profiles can be used in corrosive environments. Aluminum has a natural oxide layer that provides excellent resistance to corrosion. Additionally, it can be further protected by various surface treatments like anodizing or powder coating, enhancing its durability and resistance to corrosive elements.

- Q: What does T6 mean in aluminum alloy sections?

- In aluminium alloy section, T6 means heat treatment process. T6 solid solution heat treatment after artificial aging state, suitable for solid solution after heat treatment, no cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit) the following product T1~T7 process:T1: artificial agingT2: annealingT4: solution treatment plus natural agingT5: solid solution treatment with incomplete artificial agingT6: solid solution treatment plus full artificial agingT7: solid solution treatment plus stabilization treatment

- Q: Are aluminum profiles suitable for use in architectural lighting fixtures?

- <p>Yes, aluminum profiles are commonly used for architectural lighting fixtures due to their durability, lightweight nature, and excellent heat dissipation properties. They offer design flexibility and can be easily shaped and machined to fit various lighting designs. Additionally, aluminum's resistance to corrosion makes it ideal for both indoor and outdoor lighting applications.</p>

- Q: This question asks for an enumeration of the various types of aluminum profiles that are commonly utilized in interior wall systems.

- <p>Aluminum profiles for interior wall systems come in various types, each serving a specific purpose. These include: 1. Cover Profiles, which conceal the joints between wall panels; 2. Angle Profiles, used for creating corners and edges; 3. Connecting Profiles, facilitating the attachment of panels; 4. Support Profiles, providing structural support; 5. Joint Profiles, for aligning and securing panels at their joints; 6. Decorative Profiles, adding aesthetic appeal; 7. Insulation Profiles, for thermal insulation; and 8. Sealing Profiles, to prevent air and moisture infiltration. Each type of profile is designed to meet specific architectural and functional requirements, contributing to the overall integrity and appearance of the interior wall system.</p>

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

Send your message to us

Standard Aluminum Profiles - Aluminum Sheet Plate Stocks Warehouse Cold Rolled Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords