Extruded Aluminum Trim Profiles for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium section profiles for doors and windows Description

Aluminium section profiles for doors and windows is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium section profiles for doors and windows

Aluminum Profiles | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium section profiles for doors and windows

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium section profiles for doors and windows

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium section profiles for doors and windows

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

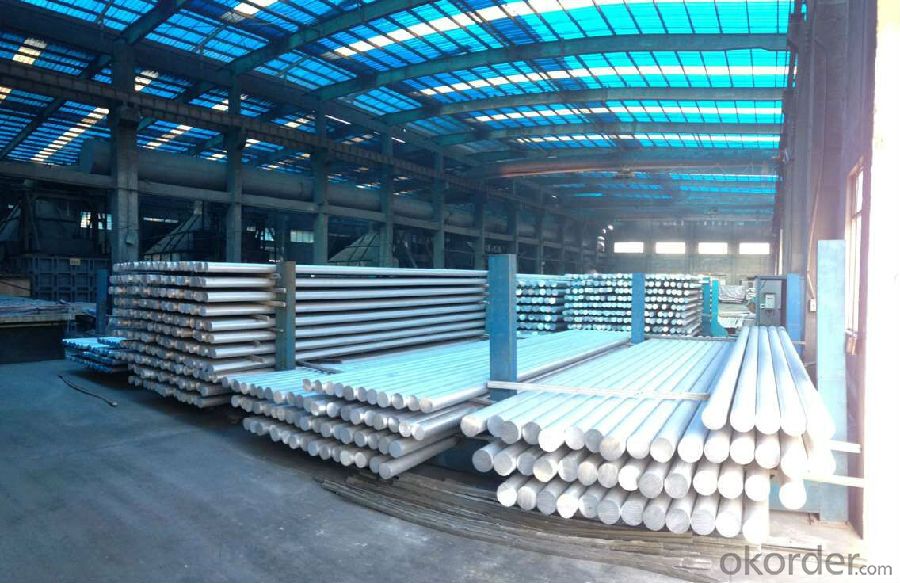

6. Image of Aluminium section profiles for doors and windows

7. Package and shipping of Aluminium section profiles for doors and windows

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for guidelines to ensure the safe and efficient installation of aluminum profiles.

- <p>To ensure the safe and effective installation of aluminum profiles, follow these steps: 1. Use high-quality aluminum profiles that meet the required specifications. 2. Accurately measure and mark the installation locations. 3. Use appropriate tools and equipment for cutting, drilling, and fastening. 4. Ensure the surface is clean, dry, and free of debris before installation. 5. Use the correct fasteners and follow the manufacturer's recommendations for torque settings. 6. Check for proper alignment and level during installation. 7. Regularly inspect and maintain the profiles to ensure they remain secure and functional. 8. Follow all safety precautions, including wearing protective gear and using secure work platforms.</p>

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: Are aluminum profiles suitable for use in the electronics industry?

- The electronics industry finds aluminum profiles to be a suitable option. Aluminum, being lightweight, durable, and resistant to corrosion, becomes an excellent choice for different electronic applications. Its exceptional thermal conductivity facilitates efficient dissipation of heat in electronic devices, which is crucial to avoid overheating and ensure optimal performance. Moreover, aluminum profiles can be easily customized and fabricated to fulfill specific design requirements, making them adaptable for various electronic components and enclosures. They also possess electromagnetic shielding properties, safeguarding sensitive electronic circuits from interference. All in all, aluminum profiles provide numerous advantages for the electronics industry, making them a popular and appropriate option for electronic devices and equipment.

- Q: This question asks if aluminum profiles can be recycled through existing recycling programs or facilities in the user's local area.

- <p>Yes, aluminum profiles can typically be recycled using existing recycling programs or facilities. Most recycling centers accept aluminum, and aluminum profiles are no exception. However, it's always a good idea to check with your local recycling program to confirm their specific guidelines and requirements. Some facilities may require aluminum profiles to be clean and free of any non-aluminum parts before recycling. You can also look for local scrapyards or metal recycling businesses that specialize in aluminum and may offer better rates for your aluminum profiles.</p>

- Q: Can aluminum profiles be used in the construction of modular buildings?

- Yes, aluminum profiles can be used in the construction of modular buildings. Aluminum profiles offer several advantages such as being lightweight, durable, corrosion-resistant, and easily recyclable. These profiles can be easily fabricated and assembled to create strong and stable modular structures. Additionally, aluminum profiles provide flexibility in design, allowing for customization and versatility in modular construction projects.

- Q: Are aluminum profiles suitable for escalator handrails?

- Indeed, escalator handrails can be made from aluminum profiles. Aluminum is a material that is both lightweight and durable, and is frequently employed in a wide range of applications, one of which being escalator handrails. It boasts a remarkable ratio of strength to weight, is resistant to corrosion, and is capable of enduring substantial loads and continuous use. Moreover, aluminum profiles can be effortlessly molded and tailored to satisfy the precise demands of escalator handrails, ensuring a pleasant and ergonomic grip for individuals. All in all, due to their strength, durability, and adaptability, aluminum profiles are a dependable and appropriate option for escalator handrails.

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is lightweight, strong, and corrosion-resistant, making it an ideal material for constructing car bodies. Its high specific strength allows for increased fuel efficiency and better performance. Additionally, aluminum profiles can be easily shaped and formed to meet the specific design requirements of modern vehicles.

- Q: How do aluminum profiles perform in terms of chemical resistance?

- Aluminum profiles exhibit good chemical resistance to many common substances, including water, air, various acids, and alkalis. However, they may corrode or react with certain aggressive chemicals, such as strong acids or bases. It is important to consider the specific chemical environment and consult relevant guidelines or experts when assessing the chemical resistance of aluminum profiles.

- Q: What are the different types of fasteners used for aluminum profiles?

- For aluminum profiles, there exists a range of fasteners that are commonly employed. These include: 1. T-slot nuts: These nuts are specifically designed to fit seamlessly into the T-slot grooves found on aluminum profiles. Equipped with a threaded hole, they enable the attachment of bolts, screws, and other fasteners. 2. Bolts and screws: These fasteners serve the purpose of securing aluminum profiles either to each other or to other components. They are available in various lengths and sizes, catering to different applications. 3. Corner brackets: Corner brackets are implemented to establish robust joints between aluminum profiles at right angles. Typically, they are equipped with holes for the easy attachment of screws or bolts. 4. T-bolts: T-bolts resemble regular bolts, with the exception of a T-shaped head that fits snugly into the T-slot grooves of aluminum profiles. This design enables rapid and secure attachment without the need for nuts or additional hardware. 5. Angle brackets: Angle brackets are utilized to establish joints between aluminum profiles at varying angles. Usually featuring holes for screws or bolts, they facilitate the secure connection of profiles. 6. Clamps: Clamps are employed to hold aluminum profiles in place or to affix them to other components. They are available in diverse designs, such as lever clamps or eccentric clamps, and can be effortlessly adjusted and tightened for a secure fit. 7. End caps: These caps are specifically designed to cover the ends of aluminum profiles, offering a polished appearance while safeguarding the profile from debris or potential damage. These examples represent merely a selection of the diverse fasteners employed for aluminum profiles. The choice of fastener ultimately depends on the specific application and the desired level of strength and versatility.

- Q: Can aluminum profiles be used for modular shelving systems?

- Indeed, modular shelving systems can effectively utilize aluminum profiles. This lightweight and robust material provides exceptional durability and corrosion resistance. Its adaptability enables its suitability for diverse applications, including shelving systems. By effortlessly customizing and adjusting aluminum profiles, one can effortlessly fashion modular shelving units of varying dimensions and layouts. Furthermore, the ease of assembly and disassembly of aluminum profiles makes them an ideal choice for adjustable or expandable modular systems. Ultimately, aluminum profiles offer a dependable and visually appealing answer for modular shelving systems.

Send your message to us

Extruded Aluminum Trim Profiles for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords