Vintage Aluminum Sheets - Aluminium Cold Drawn Plate with Best Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum sheet is widely used in the field of construction field and decoration field, etc.

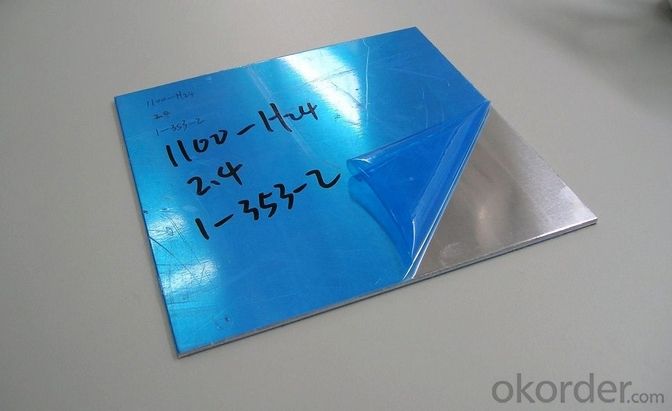

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1500mm*3000mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 7 tons/each size.

How many tons did you export in one year

Japan, UAE,Singapore, Canada, Vietnam,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,small-5-bar aluminium checkered sheet, big-5-bar checkered aluminium plate, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: General characteristics of pure aluminium plate of pure aluminium plate

- Comparison of pure aluminium sheets:1, grade: 1A85, 1A90, 1A93, 1A97, 1A99;Product type: plates, belts, foils, tubes;Main characteristics: Industrial high-purity aluminum;Applications: mainly used in the production of various electrolytic capacitor foil, acid fast container, etc., products have plates, belts, foils and so on.2, grade: 1060, 1050A, 1035;Product type: foil, wire;Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but the strength is low, it can not be strengthened by heat treatment, cutting is not good. Acceptable contact welding and gas welding;Scope of application: use the advantages of making some structures with specific properties, such as aluminum foil gasket and capacitor, electronic tube isolation network, wire and cable protective sleeve, net, wire core and aircraft parts and trim ventilation system.3, brand: 1100;Product type: Sheet & strip;Main features: for ordinary industrial pure aluminum aluminum content of 99%, can not be strengthened by heat treatment; low strength, but has good ductility, formability, weldability and corrosion resistance; anodic oxidation can improve corrosion resistance, and beautiful surface;Scope of application: mainly produces sheet metal and strip. Suitable for making all kinds of deep stamping products, and is widely used in various fields from cooking utensils to industrial equipment.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: Is it possible to use aluminum sheets as a material for exterior siding or cladding on buildings?

- <p>Yes, aluminum sheets are commonly used for siding or cladding due to their durability, lightweight, and resistance to corrosion. They are low maintenance, can be easily shaped, and come in various colors and finishes. Aluminum's resistance to weathering and its ability to withstand temperature extremes make it a popular choice for both residential and commercial buildings.</p>

- Q: How do aluminum plates open holes?

- The diameter is 15 cm, a circle of great sizeIn addition can also start at the center of the circle penetrated, and set around the line, then cut along with electric jigsaw.

- Q: What is the specific heat capacity of aluminum sheets?

- The approximate specific heat capacity for aluminum sheets is 0.897 J/g°C, indicating that to increase the temperature of 1 gram of aluminum by 1 degree Celsius, 0.897 joules of energy is needed. While the specific heat capacity may slightly differ based on the aluminum sheet's purity and specific alloy, this value serves as a fairly accurate approximation for the majority of commonly used aluminum sheets.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- Aluminum sheets and copper sheets differ in terms of conductivity. Copper is known to be an excellent conductor of electricity, being one of the most conductive metals available. It has a high electrical conductivity, which means it allows electricity to flow through it with minimal resistance. On the other hand, aluminum is also a good conductor of electricity, but it is not as conductive as copper. Aluminum has approximately 61% conductivity compared to copper. Therefore, if high conductivity is a primary requirement, copper sheets would be the better choice. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still provide sufficient conductivity for many applications. Ultimately, the choice between aluminum and copper sheets depends on the specific needs of the project and the balance between conductivity, cost, and other factors.

Send your message to us

Vintage Aluminum Sheets - Aluminium Cold Drawn Plate with Best Price in Warehouse

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords