Stair Tower for Formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

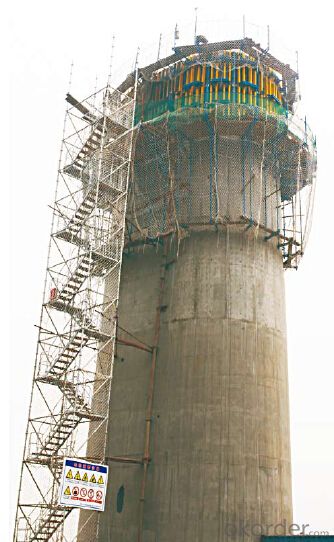

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for both interior and exterior structures?

- Yes, steel formwork can be used for both interior and exterior structures. Steel formwork is versatile and can withstand various environmental conditions, making it suitable for both indoor and outdoor construction projects.

- Q: What are the considerations when designing steel formwork for slabs?

- When designing steel formwork for slabs, there are several important considerations that need to be taken into account. Firstly, the load capacity of the formwork needs to be determined. This involves calculating the total weight of the fresh concrete, reinforcement, and any additional loads such as construction equipment or workers. The strength and stability of the steel formwork must be able to support these loads without any deformation or failure. Another consideration is the size and shape of the slab. The formwork needs to be designed to accurately replicate the desired dimensions and contours of the slab. This may involve creating custom formwork components or using adjustable formwork systems to accommodate variations in slab design. The formwork system also needs to be designed in a way that allows for easy installation and removal. This includes considering the assembly and disassembly process, as well as the handling and transportation of the formwork components. The formwork should be designed to be efficient and time-saving, while also ensuring worker safety during installation and removal. Additionally, the formwork needs to be designed to provide a smooth and even surface finish on the slab. This may involve incorporating appropriate form liners or surface treatments to achieve the desired aesthetic outcome. The formwork should also be designed to prevent any leakage of fresh concrete, as this can result in defects or imperfections on the slab surface. Finally, the durability and reusability of the formwork need to be considered. Steel formwork is often chosen for its strength and longevity, but it is important to ensure that the formwork can withstand repeated use without any significant deterioration or damage. Proper maintenance and storage practices should also be implemented to extend the lifespan of the formwork. In conclusion, designing steel formwork for slabs requires careful consideration of load capacity, slab size and shape, installation and removal processes, surface finish requirements, and durability. These considerations are essential to ensure a successful and efficient construction process while meeting the desired quality standards for the slab.

- Q: How does steel formwork contribute to sustainable construction?

- Steel formwork contributes to sustainable construction in several ways: 1. Durability: Steel formwork is highly durable and can be reused multiple times, reducing the need for frequent replacements. This reduces the consumption of materials and decreases waste generation, making it an environmentally friendly choice. 2. Energy Efficiency: Steel formwork requires less energy for manufacturing compared to other materials like wood or plastic. This results in lower carbon emissions during the production process, contributing to reduced greenhouse gas emissions. 3. Waste Reduction: The use of steel formwork minimizes construction waste. Unlike traditional formwork materials that are often discarded after a single use, steel formwork can be easily dismantled, cleaned, and reused for future projects. This reduces the amount of waste sent to landfills and promotes a circular economy. 4. Increased Construction Speed: Steel formwork is known for its speed and efficiency in construction projects. Its modular design allows for quick assembly and disassembly, reducing construction time and energy consumption. This, in turn, minimizes the disturbance to the surrounding environment and reduces the overall carbon footprint of the project. 5. Improved Safety: Steel formwork provides a stable and secure platform for workers during the construction process. Its strength and rigidity reduce the risk of accidents and injuries, ensuring a safer working environment for construction workers. This leads to lower healthcare costs and increased worker productivity. Overall, the use of steel formwork in construction promotes sustainability by reducing waste, energy consumption, and carbon emissions. Its durability, reusability, and efficiency make it a valuable option for sustainable construction practices.

- Q: How does steel formwork handle different concrete surface coloring techniques?

- Steel formwork is a versatile and durable material that can handle different concrete surface coloring techniques effectively. The primary advantage of using steel formwork is its smooth and non-porous surface, which ensures that the concrete's coloring techniques are evenly applied and achieve the desired result. When it comes to concrete surface coloring techniques such as staining, stamping, or integral coloring, steel formwork provides a stable and consistent base for these processes. The smooth surface of steel formwork allows for an even distribution of colorants or pigments, ensuring that the final concrete surface has a uniform and appealing appearance. Additionally, steel formwork's strength and rigidity make it suitable for various concrete surface coloring techniques. Whether it is stamping, which involves pressing textured patterns onto the concrete surface, or staining, which requires precise application of colorants, steel formwork provides the necessary support and stability for these techniques to be executed accurately. Furthermore, steel formwork's durability makes it resistant to damage during the coloring process. Concrete surface coloring techniques often involve the use of chemicals, dyes, or stains that can potentially cause damage to weaker or less resistant formwork materials. However, steel formwork's robustness allows it to withstand the harsh chemicals and coloring agents without compromising its structural integrity. In summary, steel formwork is an excellent choice for handling different concrete surface coloring techniques. Its smooth and non-porous surface ensures even distribution of colorants, while its strength and rigidity provide the necessary support for techniques such as stamping or staining. Additionally, steel formwork's durability makes it resistant to damage caused by chemicals or coloring agents, ensuring a successful and aesthetically pleasing outcome.

- Q: What are the typical sizes and dimensions of steel formwork panels?

- The typical sizes and dimensions of steel formwork panels vary depending on the specific application and project requirements. However, there are some common standard sizes that are widely used in the construction industry. For wall formwork, the typical size of steel formwork panels is around 2.4 meters in height and 0.6 meters in width. These panels are usually available in various thicknesses ranging from 12mm to 18mm. They are designed to be easily connected and stacked together to form a sturdy and stable wall formwork system. For slab formwork, the dimensions of steel panels are typically larger. The standard size for slab formwork panels is around 1.2 meters in width and varies in length depending on the desired slab size. These panels are also available in different thicknesses to support the weight and load requirements of the concrete slab. In addition to the standard sizes, customized steel formwork panels can be manufactured to meet specific project needs. These custom panels can be designed to have specific dimensions, shapes, and configurations to accommodate irregular or unique construction requirements. It is important to note that while steel formwork panels provide strength and durability, they can be heavy and require appropriate lifting and handling equipment for installation and removal. Additionally, proper safety measures should be followed during the use of steel formwork panels to ensure worker safety and project success.

- Q: How does steel formwork handle concrete finishing and curing agents?

- Steel formwork is highly resistant to the chemical agents commonly used in concrete finishing and curing processes. Its durable and non-absorbent surface prevents the concrete from adhering to the formwork, allowing for easy release and smooth finishing of the concrete surface. Additionally, the steel formwork's rigidity and stability ensure that the concrete maintains its desired shape and prevents any deformation during the curing process.

- Q: Can steel formwork be used for energy-efficient concrete buildings?

- Yes, steel formwork can be used for energy-efficient concrete buildings. Steel formwork provides excellent strength and durability, allowing for the construction of complex concrete structures with high thermal performance. Additionally, steel formwork can be easily reused multiple times, reducing waste and promoting sustainability in the construction industry.

- Q: How does steel formwork handle different concrete surface repair techniques?

- Steel formwork proves to be a versatile and durable choice for managing various techniques used in concrete surface repair. The primary advantage of steel formwork lies in its ability to withstand the pressures and stresses associated with concrete repairs. When it comes to methods like patching or resurfacing, steel formwork acts as a sturdy and stable framework for containing the concrete mixture. It can bear the weight of the repair materials and the pressure exerted by the concrete during the setting and curing process. This guarantees proper containment of the repair and ensures the achievement of the desired shape and dimensions. Moreover, steel formwork offers flexibility in terms of shape and design. It can be easily customized to meet different repair requirements, whether it involves straight surfaces, curves, or complex geometries. The strength of steel enables the creation of intricate formwork structures capable of handling even the most challenging repair projects. Furthermore, steel formwork exhibits excellent reusability and durability. It can be reused multiple times without significant wear and tear, making it a cost-effective solution for numerous repair projects. This durability ensures the formwork's integrity remains intact throughout the repair process, preventing any potential issues and maintaining the repair's quality. Additionally, steel formwork possesses resistance to moisture and chemicals, commonly present in concrete repairs. This resistance ensures that the formwork remains in good condition, avoiding any corrosion or deterioration when in contact with the repair materials. This becomes particularly crucial for long-term repairs where the formwork may remain in place for an extended period. In conclusion, steel formwork emerges as a dependable and efficient option for managing various concrete surface repair techniques. Its strength, flexibility, reusability, and resistance to moisture and chemicals make it an ideal choice for containing and shaping the repair materials, ultimately leading to successful and durable repairs.

- Q: How does steel formwork contribute to better site organization?

- Steel formwork contributes to better site organization in several ways. Firstly, steel formwork is highly durable and reusable, which means it can be used multiple times on different construction projects. This eliminates the need for frequent replacement and reduces waste on site. The ability to reuse steel formwork also reduces storage space requirements, as it can be easily stacked and stored when not in use. Secondly, steel formwork is adjustable and customizable, allowing it to be easily modified to fit different shapes and sizes of concrete structures. This flexibility enables efficient use of space on site, as the formwork can be tailored to the specific requirements of each project. This ensures that the construction process is organized and streamlined, minimizing the need for additional materials or adjustments. Furthermore, steel formwork is known for its high strength and stability, which enhances site safety. Its robust structure provides a secure platform for workers to carry out their tasks, reducing the risk of accidents or injuries. This promotes a safer working environment and improves overall site organization. Steel formwork also contributes to better site organization by facilitating faster construction cycles. Its quick assembly and disassembly process allows for efficient and smooth workflow, enabling construction projects to be completed in a timely manner. This helps to minimize delays and ensures that the site is well-organized and productive. Lastly, steel formwork can be easily integrated with other construction systems and technologies. This compatibility allows for seamless coordination between different components of the project, promoting better site organization. Whether it is integrating with scaffolding systems or connecting to other structural elements, steel formwork ensures a cohesive and well-organized construction site. In conclusion, steel formwork contributes to better site organization through its durability, adjustability, strength, and compatibility with other construction systems. Its ability to be reused, customized, and integrated with other components enhances efficiency, safety, and productivity on construction sites.

- Q: How does steel formwork contribute to easier formwork removal?

- Steel formwork offers several advantages that contribute to easier formwork removal. Firstly, its high strength and durability enable it to withstand the pressure and weight of the concrete without deforming or warping. As a result, the formwork remains undamaged and intact after the concrete is poured and cured. Secondly, the smooth surfaces of steel formwork facilitate the easy release of the cured concrete. The absence of sticking between the concrete and the formwork simplifies the removal process, especially when dealing with complex shapes and intricate designs. Consequently, the formwork can be removed effortlessly without causing any harm to the concrete. Moreover, steel formwork often incorporates detachable parts or panels, allowing for convenient assembly and disassembly. This feature not only speeds up the removal process but also simplifies the cleaning and maintenance of the formwork. Consequently, the formwork remains in good condition, ensuring its longevity and reusability. Additionally, steel formwork exhibits remarkable resistance to moisture and chemicals commonly encountered in the construction environment. This resistance prevents the formwork from deteriorating or weakening over time. Consequently, the formwork remains intact and in excellent condition, making it easier to remove after the concrete has set. In summary, the strength, durability, smooth surfaces, detachable parts, and resistance to moisture and chemicals make steel formwork an ideal choice for easier formwork removal. This not only simplifies the process but also guarantees the quality and integrity of the concrete structure being constructed.

Send your message to us

Stair Tower for Formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords