Hot Rolled Stainless Steel Grade 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

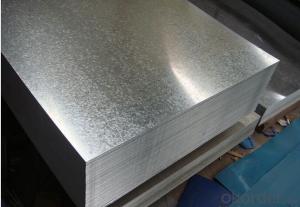

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1) Good ductility

(2) Good corrosion resistance

(3) Excellent abrasion resistance and fatigue strength

(4) Good weldability

(5) Oxidation resistant performance

(6) Excellent in high temperature

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

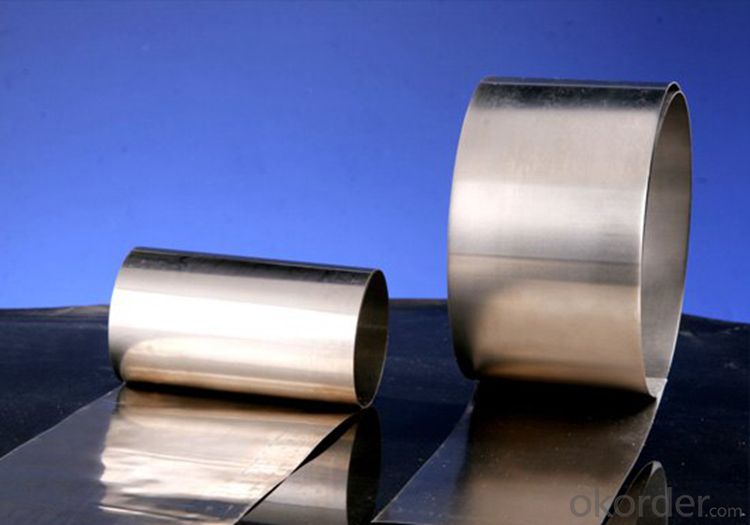

Detail picture of Products:

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Are stainless steel sheets suitable for outdoor sculptures?

- Yes, stainless steel sheets are suitable for outdoor sculptures. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for outdoor use. Its strength and ability to withstand various weather conditions make it ideal for sculptures that are exposed to the elements.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are widely used in the food industry due to their numerous beneficial properties. One common use of stainless steel sheets in the food industry is for food processing equipment. These sheets are used to fabricate machines such as mixing tanks, conveyors, and food processing tables. Stainless steel sheets are preferred for this purpose because they are resistant to corrosion, easy to clean, and do not react with food substances, ensuring the food's safety and hygiene. Another common use of stainless steel sheets in the food industry is for food storage and transportation. Stainless steel sheets are often used to manufacture containers, tanks, and barrels that are used to store and transport food products. The corrosion resistance of stainless steel ensures that the food is protected from contamination and spoilage during storage and transportation. Stainless steel sheets are also used for kitchen equipment in the food industry. Countertops, sinks, and cabinets are frequently made from stainless steel sheets due to their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment such as ovens, grills, and refrigerators. These sheets are crucial in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In summary, stainless steel sheets are commonly used in the food industry for food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Indeed, outdoor furniture can make use of stainless steel sheets. Stainless steel, a material known for its exceptional durability and resistance to rust, corrosion, and weathering, proves to be an excellent choice. Its ability to withstand the elements ensures that it maintains its appearance and structural integrity over time, making it the perfect option for outdoor furniture. Moreover, stainless steel possesses a sleek and contemporary aesthetic that complements a wide range of outdoor design styles. Whether one seeks stainless steel sheets for tables, chairs, or any other outdoor furniture pieces, they can be assured of a visually appealing and enduring choice.

- Q: Are stainless steel sheets resistant to staining from food?

- Yes, stainless steel sheets are highly resistant to staining from food. Stainless steel is known for its excellent corrosion resistance and non-reactivity with various substances, including food. It is a popular choice for kitchen appliances and cookware due to its ability to withstand prolonged exposure to food without staining or reacting chemically. Stainless steel sheets are also easy to clean, making them ideal for food preparation areas where cleanliness is essential. Additionally, the smooth and non-porous surface of stainless steel sheets prevents the absorption of food particles and liquids, reducing the risk of staining. Overall, stainless steel sheets provide a durable and stain-resistant option for food-related applications.

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility. Stainless steel has excellent electrical conductivity and high magnetic permeability, which helps in shielding electromagnetic interference (EMI) and radio frequency interference (RFI). It is commonly used in applications where electromagnetic compatibility is required, such as enclosures, cabinets, and shielding components in electronic devices.

- Q: Are stainless steel sheets suitable for elevator floor panels?

- Yes, stainless steel sheets are suitable for elevator floor panels. Stainless steel is a strong and durable material that is resistant to corrosion, making it a suitable choice for high-traffic areas like elevator floors. It is also easy to clean and maintain, making it ideal for public spaces. Additionally, stainless steel sheets can be customized in terms of size, shape, and finish to meet specific design requirements and aesthetic preferences. Overall, stainless steel sheets offer a combination of durability, aesthetic appeal, and ease of maintenance that make them well-suited for elevator floor panels.

- Q: Stainless steel wire drawing without fingerprints, what principle?

- Let's say the principle: the material surface is easy to leave the fingerprint because the material has the characteristics of specular reflection on the light. The material is smooth enough, and the light is not diffusely reflective on the material, mainly specular. Landlord with your finger press the glass mirror will know

- Q: Can stainless steel sheets be polished?

- Stainless steel sheets, indeed, possess the ability to undergo polishing. The act of polishing these sheets serves the purpose of enhancing their visual appeal, resulting in the creation of a sleek and lustrous surface. This procedure typically entails the utilization of abrasive substances like sandpaper, polishing compounds, or specialized machinery in order to eliminate any flaws or marks present on the stainless steel sheet's surface. This task can be accomplished both manually or with the assistance of specific equipment. By polishing stainless steel sheets, not only does their aesthetic allure become enhanced, but their susceptibility to corrosion and staining is also significantly reduced.

Send your message to us

Hot Rolled Stainless Steel Grade 316 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords