Galvanized Steel Coils Made In China With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR GALVANIZED STEEL COILS:

Mian Quality Standard | JIS G3302, EN10346, DIN17162, ASTM A653/653M, GB2518 |

Process | hot dip galvanizing |

Process Speed | 1#. Max 120m/min, 2#. Max 130m/min |

Thickness | 1#. 0.25mm upto 1.20mm, 2#. 0.25mm upto 1.0mm |

Width | 900mm upto 1300mm |

Surface Finish | zero spangles, skinpassed, oiled,chromated, tension level, |

Coating | zinc layer mass on both sides from 30 g/m2 upto 180g/m2 |

Yield Strength | 220Mpa upto 750Mpa |

Weight per Coil | max 15,000kg |

Inner Diameter | φ 508mm |

Outer Diameter | max φ 2,050mm |

Finished Internal Diameter | Φ 508mm or φ 610mm |

Finished Coil Weight | 1#. max 10,000kg, 2#. max 15,000kg |

Packing | Mill's Export Standard Packing |

Capacity | 300,000 tons/year |

EXPORT STANDARD FOR GALVANIZED STEEL COILS:

-Axial and circumferential steel straps with seal (4 steel straps each)

-VCI Anti-rust kraft paper

-Water-proofing plastic

-Pearl wool (coil surface)

-Steel cover (coil surface/bore)

-Plastic cover (coil sides)

-Inside and outside corner protectors

Or According customers' requirements(Usually only for domestic)

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

PACKAGING &DELIVERY FOR GALVANIZED STEEL COILS:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS FOR GALVANIZED STEEL COILS:FOB, CFR, CIF

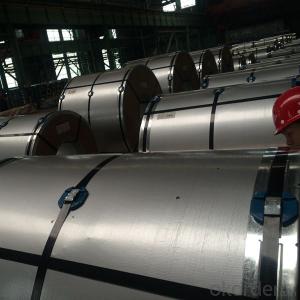

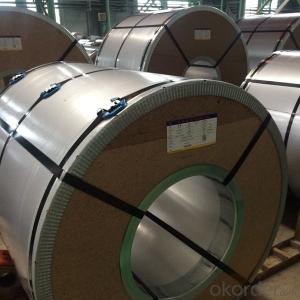

DETAILED PICTURES FOR GALVANIZED STEEL COILS:

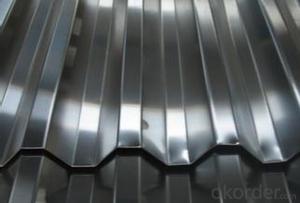

APPLICATION FOR GALVANIZED STEEL COILS:

Galvanized steel products are mainly used in construction, light industry, automobile, agriculture , fishery and commercial industries. They have great advantages:1.it has small harm to the environment and it can be recycled, greatly lighten the stress to the environment.2.it is convenient to process,easy to construct and has good waterproof effect.

FAQ FOR GALVANIZED STEEL COILS:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

- Q: What is the standard size of a stainless steel sheet?

- The standard size of a stainless steel sheet can vary depending on the manufacturer and the specific application. However, in general, stainless steel sheets are commonly available in standard sizes of 4 feet by 8 feet (1220mm by 2440mm) or 4 feet by 10 feet (1220mm by 3050mm). These dimensions are widely used in various industries such as construction, manufacturing, and fabrication. Additionally, stainless steel sheets may also come in different thicknesses, ranging from 0.4mm to 6mm or more, depending on the intended use and requirements. It is important to note that custom sizes and dimensions can also be obtained from manufacturers for specific projects or applications that require non-standard sizes.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or decorative pieces. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it an ideal choice for outdoor applications. Additionally, its sleek and polished appearance adds a touch of elegance and modernity to any outdoor space.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Yes, stainless steel sheets are suitable for elevator control panels. Stainless steel is known for its durability, resistance to corrosion, and ease of maintenance, making it a popular choice for various applications including elevator control panels. It provides a sleek and modern appearance, can withstand constant use and touch, and is easy to clean and disinfect, making it an ideal material for elevator control panels.

- Q: What are the different methods of cutting stainless steel sheets?

- There are several methods available for cutting stainless steel sheets, depending on the specific requirements and desired precision. 1. Shearing: This is one of the most common methods used for cutting stainless steel sheets. It involves using a shearing machine with sharp blades to cut through the material. Shearing is ideal for straight cuts and is relatively fast and cost-effective. 2. Laser cutting: Laser cutting is a highly precise method that uses a high-powered laser beam to cut through stainless steel sheets. It provides a clean and smooth cut, and can be used to create intricate designs or complex shapes. Laser cutting is widely used in industries that require high precision and quality finishes. 3. Plasma cutting: Plasma cutting uses a high-temperature plasma arc to melt through stainless steel sheets. This method is suitable for cutting thick stainless steel sheets or materials with high conductivity. Plasma cutting offers fast cutting speeds and can handle various shapes and thicknesses. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure jet of water mixed with abrasive particles to cut through stainless steel sheets. This method is highly versatile and can create complex shapes with high precision. Waterjet cutting is also a cold cutting process, which means it does not produce heat-affected zones or alter the material's structure. 5. Abrasive cutting: This method uses an abrasive wheel or disc to grind and cut through stainless steel sheets. It is commonly used for rough cuts or in situations where other methods are not feasible. Abrasive cutting can be done manually or with the help of power tools, such as angle grinders. Each of these cutting methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the stainless steel sheet, desired precision, budget, and production requirements.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of both size and shape. They can be cut, bent, or shaped according to specific requirements, allowing for a wide range of customization options.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Yes, stainless steel sheets are highly suitable for hygienic applications. Stainless steel has excellent corrosion resistance properties, making it ideal for environments that require strict cleanliness and hygiene standards. It is non-porous, which means it does not absorb liquids or harbor bacteria, making it easy to clean and maintain. Additionally, stainless steel has a smooth and polished surface, which further prevents the accumulation of dirt, grime, and bacteria. Its durability and strength make it resistant to scratches and dents, ensuring a long-lasting and hygienic surface. Stainless steel sheets are commonly used in the food and beverage industry, pharmaceutical industry, healthcare facilities, and laboratories due to their hygienic properties.

- Q: What are the standard dimensions for stainless steel sheets?

- The standard dimensions for stainless steel sheets vary depending on the type and grade of stainless steel being used. However, there are some common sizes that are widely available in the market. For most stainless steel sheets, the standard width ranges from 36 inches to 48 inches, with a length varying between 72 inches to 120 inches. These dimensions are commonly used for stainless steel sheets used in various applications such as construction, automotive, and manufacturing. The thickness of stainless steel sheets can also vary, with common options ranging from 0.024 inches to 0.1875 inches. Thinner sheets are often used for decorative purposes or lightweight applications, while thicker sheets are utilized for heavy-duty applications that require higher strength and durability. It is important to note that these dimensions are general guidelines and can vary depending on the specific requirements of a project. Additionally, custom sizes can also be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for various industries and purposes, ensuring that there is flexibility in selecting the appropriate size for a specific project.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Food packaging equipment can greatly benefit from the use of stainless steel sheets. The food industry favors stainless steel because of its many advantageous features. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. As a result, it is safe for direct contact with food products. Furthermore, stainless steel is resistant to corrosion, rust, and staining, ensuring the equipment's durability and longevity. Cleaning and sanitizing stainless steel is also a breeze, making it perfect for maintaining the high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process even further. Moreover, stainless steel possesses excellent strength and heat resistance properties, allowing it to withstand high temperatures without losing its shape or structural integrity. This is especially crucial in food packaging equipment that involves heat sealing or thermal processing. To sum up, stainless steel sheets are an excellent choice for food packaging equipment due to their non-reactive nature, resistance to corrosion, ease of cleaning, and high strength. These qualities ensure both the safety and quality of food products during packaging processes, making stainless steel a reliable and hygienic option.

- Q: Can stainless steel sheets be used for medical implant devices?

- Yes, stainless steel sheets can be used for medical implant devices. Stainless steel is a widely used material in the medical industry due to its excellent mechanical properties, corrosion resistance, and biocompatibility. It is known for its strength, durability, and ability to withstand sterilization processes. Stainless steel sheets can be fabricated into various medical implant devices such as plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and many others. The high strength-to-weight ratio of stainless steel makes it suitable for load-bearing applications, while its resistance to corrosion ensures longevity within the body. Furthermore, stainless steel is a biocompatible material, which means it is well-tolerated by the human body and does not cause adverse reactions or allergies. The surface of stainless steel can be modified to enhance its biocompatibility by processes like passivation or coating. It is important to note that the selection of the appropriate stainless steel grade and surface finish is crucial for medical implant devices to ensure compatibility with the specific body tissue and environment. Additionally, thorough testing and regulatory approval are required to ensure the safety and efficacy of stainless steel medical implant devices. In conclusion, stainless steel sheets can indeed be used for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Proper selection, testing, and regulatory approval are essential to ensure the suitability and safety of stainless steel implants in medical applications.

Send your message to us

Galvanized Steel Coils Made In China With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords