Stainless steel plate/sheet 304,201,202,309S,316L,321,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

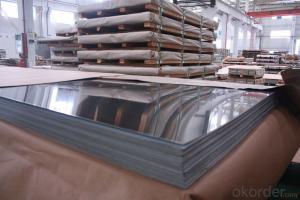

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: Can stainless steel sheets be used for medical implants?

- Medical implants can indeed utilize stainless steel sheets. In the medical realm, stainless steel is frequently employed due to its remarkable resistance to corrosion, its strength, and its affordability. It is also biocompatible, meaning that it does not provoke any undesirable reactions when in contact with bodily tissues or fluids. To meet the distinct demands of medical implants, such as orthopedic plates, bone screws, dental implants, and cardiovascular stents, stainless steel sheets can be manufactured into a variety of shapes and sizes. Furthermore, stainless steel is easily cleanable and sterilizable, rendering it well-suited for implantation within the human body. However, it is important to note that different grades of stainless steel may possess varying attributes. As a result, it is crucial to choose the appropriate grade based on the specific application and requirements of the medical implant.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for pool construction. It is highly resistant to chemicals and can withstand the harsh conditions of a swimming pool environment, including exposure to chlorine and saltwater. Stainless steel sheets are also easy to clean and maintain, making them a popular option for both residential and commercial swimming pools. Additionally, stainless steel offers a sleek and modern aesthetic, enhancing the overall appearance of the pool. However, it is important to ensure that the stainless steel sheets used in pool construction are of high quality and meet industry standards to ensure long-lasting performance and safety.

- Q: How do you calculate the bending radius for stainless steel sheets?

- To calculate the bending radius for stainless steel sheets, you need to consider the material's thickness, tensile strength, and the desired level of bendability. The bending radius can be determined using formulas or tables specific to stainless steel, taking into account these factors to ensure the sheet does not crack or deform during bending.

- Q: Can stainless steel sheets be used in food processing industry?

- Indeed, the food processing industry can utilize stainless steel sheets. This industry favors stainless steel due to its corrosion resistance, ease of cleaning, and non-reactivity with food and beverages. Moreover, its strength and durability render it appropriate for a range of purposes such as food preparation surfaces, storage containers, and equipment. Furthermore, stainless steel sheets possess a smooth and non-porous surface, effectively impeding bacterial growth and ensuring food safety. In summary, stainless steel sheets prove to be a dependable and hygienic option for implementation in the food processing industry.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Yes, stainless steel sheets can be used for oil and gas pipelines. Stainless steel is commonly used in the oil and gas industry due to its excellent corrosion resistance properties. It can withstand the harsh conditions of transportation and storage of oil and gas, including high-pressure, high-temperature, and corrosive environments. Stainless steel sheets are often utilized to fabricate pipeline components such as pipes, fittings, and flanges, as they offer durability, strength, and resistance to corrosion, which helps to prevent leaks and maintain the integrity of the pipeline.

- Q: Can stainless steel sheets be used for pharmaceutical storage cabinets?

- Yes, stainless steel sheets can be used for pharmaceutical storage cabinets. Stainless steel is highly resistant to corrosion, making it an ideal material for storing pharmaceuticals, which often require sterile and hygienic conditions. Stainless steel is also easy to clean and maintain, ensuring that the storage cabinets remain contamination-free. Additionally, stainless steel is durable and long-lasting, providing a reliable and secure storage solution for pharmaceuticals.

- Q: What are the different types of perforations available for stainless steel sheets?

- Stainless steel sheets offer several options for perforations, each with its own purpose and characteristics. Here are some of the most common types available: 1. Round Perforations: The most widely used type, these consist of evenly spaced round holes punched through the sheet. They provide good airflow, visibility, strength, and durability. 2. Square Perforations: Similar to round perforations, square ones have evenly spaced square holes. They are preferred for a more modern and geometric aesthetic, creating visually appealing patterns. 3. Slotted Perforations: These have elongated, rectangular holes for better drainage and airflow. They are ideal for grilles, screens, and filters. 4. Hexagonal Perforations: Featuring hexagon-shaped holes, this type offers an interesting visual pattern and increased strength and rigidity. 5. Decorative Perforations: Designed to enhance the aesthetic appeal, these come in various shapes, sizes, and patterns such as floral or custom designs. They are commonly used in architecture, interior design, and decorative panels. 6. Micro Perforations: These are extremely small and closely spaced holes for applications requiring high precision and fine filtering, like speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

- Q: How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, you can follow a few key steps. First, ensure that the stainless steel is properly cleaned and free from any contaminants that may promote corrosion. Additionally, avoid exposing the stainless steel sheets to environments with high chloride concentrations or acidic substances as they can accelerate stress corrosion cracking. It is also important to reduce any residual stresses in the material by utilizing proper fabrication techniques and avoiding excessive cold working. Finally, selecting the appropriate stainless steel grade for the specific application, such as those with improved resistance to stress corrosion cracking, can greatly help in preventing this type of corrosion.

- Q: What are the different types of stainless steel sheet edge treatments available?

- There are several different types of stainless steel sheet edge treatments available, each offering unique benefits and aesthetic options. 1. Mill Edge: This is the most common type of edge treatment, where the stainless steel sheet is produced with a straight, unfinished edge. It is cost-effective and suitable for most applications where appearance is not a primary concern. 2. Slit Edge: In this treatment, the stainless steel sheet is slit to the desired width, resulting in a smooth edge. Slit edge sheets are commonly used in applications where a clean, burr-free finish is required, such as in food processing or pharmaceutical industries. 3. Deburred Edge: This treatment involves removing any burrs or sharp edges from the stainless steel sheet. It provides a smooth, safe edge and is often used in applications where safety is a concern, such as in architectural or automotive applications. 4. Rolled Edge: A rolled edge treatment involves bending the stainless steel sheet to create a rounded edge. This type of treatment is commonly used in applications where safety and aesthetics are important, such as in kitchen appliances or decorative pieces. 5. Beveled Edge: In a beveled edge treatment, the stainless steel sheet is cut at an angle to create a diagonal edge. Beveled edges are often used in architectural applications to create a smooth transition between different materials or to enhance the overall design. These are just a few examples of the different types of stainless steel sheet edge treatments available. The choice of edge treatment will depend on the specific requirements of the application, including functionality, safety, and aesthetics.

- Q: How do you prevent galling when using stainless steel sheets?

- To prevent galling when using stainless steel sheets, it is important to apply a lubricant or anti-seize compound on the surface before any contact or movement occurs. This helps to reduce friction and allows for smoother motion, preventing the occurrence of galling. Additionally, using proper tools and techniques, such as using low cutting speeds and avoiding excessive pressure, can also help prevent galling in stainless steel sheet applications.

Send your message to us

Stainless steel plate/sheet 304,201,202,309S,316L,321,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords