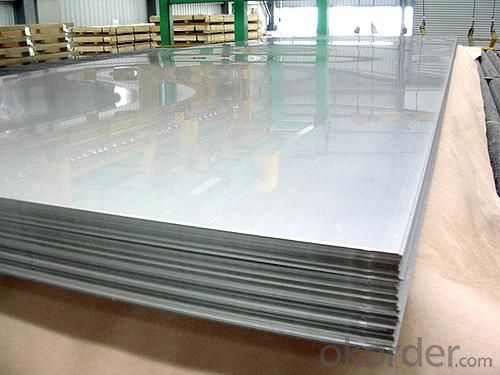

Stainless Steel Sheet Gauge22 #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers durability, corrosion resistance, and aesthetic appeal, making it suitable for various architectural purposes such as cladding, roofing, decorative elements, and structural components. Its sleek, modern look and ability to withstand harsh environmental conditions make stainless steel sheets a popular choice in the construction industry.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- 304 stainless steel surface quality of pickling process mainly depends on the heat treatment, surface oxidation Pihou formation if heat treatment before a process, or organization is not uniform, with acid does not improve the surface smoothness and uniformity. Therefore, attention should be paid to heat treatment or surface cleaning prior to heat treatment.

- Q: Why do drill holes burn on stainless steel plates? What's the best way to drill them?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: What is the thermal expansion rate of stainless steel sheets?

- The thermal expansion rate of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel, but generally, it ranges from about 10-17 parts per million per degree Celsius (ppm/°C).

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility (EMC). Stainless steel has good electrical conductivity and is often used as a shielding material to prevent the interference of electromagnetic fields. It can effectively block electromagnetic radiation and provide a barrier against external electromagnetic waves. Additionally, stainless steel's durability and corrosion resistance make it suitable for long-term EMC applications.

- Q: Are stainless steel sheets resistant to caustic soda?

- Yes, stainless steel sheets are generally resistant to caustic soda. Caustic soda, also known as sodium hydroxide, is a highly corrosive substance, but stainless steel is known for its excellent corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with caustic soda. However, it is important to note that the exact resistance of stainless steel to caustic soda may vary depending on the grade or type of stainless steel. Therefore, it is always recommended to consult the specific material specifications or consult with a qualified professional to ensure the appropriate choice of stainless steel for specific applications involving caustic soda.

- Q: Can stainless steel sheets be used for signage?

- Yes, stainless steel sheets can be used for signage. Stainless steel is a durable and weather-resistant material, making it suitable for both indoor and outdoor signage applications. It offers a sleek and professional look, and can be customized with various finishes and colors to meet specific design requirements.

- Q: Can stainless steel sheets be used for water filtration systems?

- Certainly, water filtration systems can make use of stainless steel sheets. Due to their outstanding corrosion resistance and durability, stainless steel is widely employed in water filtration. It possesses the ability to withstand high pressure, temperature fluctuations, and exposure to various chemicals, rendering it suitable for prolonged use in water filtration applications. Moreover, the smooth surface of stainless steel sheets facilitates effortless cleaning and prevents the accumulation of bacteria and other impurities. Furthermore, stainless steel is a non-reactive material, guaranteeing the absence of any harmful substances in the filtered water and ensuring its safety for consumption. In conclusion, stainless steel sheets are a dependable and efficient choice for water filtration systems.

- Q: How do you prevent galling when using stainless steel sheets?

- To prevent galling when utilizing stainless steel sheets, there are several precautions that can be taken: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound to the contact surfaces in order to decrease friction. This will establish a barrier between the stainless steel sheets, preventing sticking and galling. 2. Ensure proper surface finish: Verify that the stainless steel sheets possess a smooth surface finish. Rough or uneven surfaces heighten the likelihood of galling. Consider implementing sheets with a polished or finely ground finish to minimize the chance of galling. 3. Regulate contact pressure: Refrain from applying excessive pressure when working with stainless steel sheets. Excessive pressure generates heat and intensifies friction, leading to galling. Adjust the pressure to a level that allows for smooth movement without excessive friction. 4. Decrease sliding or rubbing: Diminish the amount of sliding or rubbing between stainless steel sheets. If feasible, employ rolling or lifting techniques instead of dragging or sliding the sheets against each other. This will minimize the risk of galling by reducing the contact area and friction. 5. Utilize compatible materials: When utilizing stainless steel sheets in conjunction with other materials, ensure compatibility. Certain materials, such as aluminum or specific coatings, can promote galling when in contact with stainless steel. Opt for materials that are less prone to galling or utilize protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat heightens the likelihood of galling in stainless steel sheets. Guarantee that the temperature is controlled and does not reach levels that could significantly heat up the sheets. This can be achieved through proper cooling methods or by implementing heat-resistant materials, if necessary. By adhering to these preventative measures, the risk of galling when utilizing stainless steel sheets can be significantly reduced. This will result in smooth operation and prolong the lifespan of the sheets.

Send your message to us

Stainless Steel Sheet Gauge22 #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords