Stainless Steel sheet and plate with Large Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

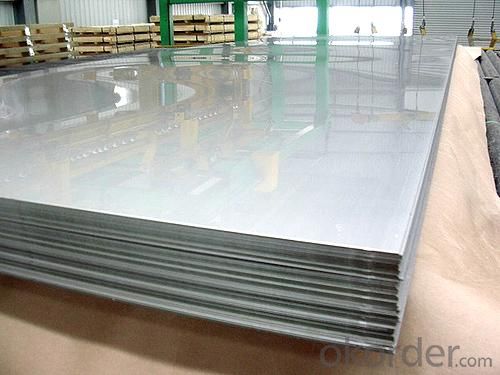

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are highly resistant to humidity. Their composition, primarily consisting of iron, chromium, and nickel, forms a protective layer that prevents corrosion and rusting even in high humidity environments. This makes stainless steel sheets an excellent choice for applications where moisture resistance is crucial, such as in kitchen and bathroom fixtures, outdoor structures, and marine equipment.

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To avoid fingerprints and smudges on stainless steel sheets, several effective techniques can be employed: 1. Opt for a microfiber cloth: Employ a soft microfiber cloth to gently wipe the stainless steel surface. Microfiber is gentle and will not cause any scratches or streaks. Avoid using rough materials such as paper towels or abrasive sponges. 2. Utilize a stainless steel cleaner: Invest in a high-quality stainless steel cleaner that is specifically designed to eliminate fingerprints and smudges. Adhere to the cleaner's instructions and evenly apply it to the surface using a cloth or sponge. Remove any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Dab a small amount of baby oil or mineral oil onto a cloth and delicately rub it over the stainless steel surface. This will create a thin protective layer that aids in preventing fingerprints and smudges from adhering to the metal. 4. Avoid direct contact with bare hands: Fingerprints and smudges often result from direct contact with hands. Endeavor to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will minimize the transfer of oils and residue onto the surface. 5. Establish a regular cleaning routine: Implement a consistent cleaning regimen for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will hinder the accumulation of oils and grime, thereby reducing the likelihood of fingerprints and smudges. By adhering to these methods, you can effectively thwart the occurrence of fingerprints and smudges on stainless steel sheets, preserving their cleanliness and shine for an extended duration.

- Q: Are stainless steel sheets magnetic?

- Yes, stainless steel sheets can be magnetic. The magnetic properties of stainless steel sheets depend on their composition. Generally, stainless steel is a non-magnetic material. However, certain grades of stainless steel, such as the 400 series (e.g., 410, 416, 420, and 430), contain a higher amount of ferritic or martensitic structures, which can exhibit magnetic properties. On the other hand, the commonly used 300 series stainless steel (e.g., 304 and 316) is non-magnetic due to its austenitic structure. Therefore, it is important to consider the specific grade of stainless steel when determining its magnetic behavior.

- Q: Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Due to their high melting point and excellent heat resistance, stainless steel sheets do not easily ignite or contribute to the spread of fire, making them ideal for applications where fire safety is crucial.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel is a universal stainless steel material, antirust performance than the 200 series of stainless steel material stronger. High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade.

- Q: Can stainless steel sheets be welded?

- Stainless steel sheets are indeed weldable. This versatile material allows for welding through various techniques, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or spot welding. However, the ideal welding method depends on the specific type of stainless steel and the thickness of the sheet. To ensure a robust and long-lasting weld, it is crucial to focus on surface preparation, cleanliness, and the use of suitable filler materials. Furthermore, it's worth noting that stainless steel possesses higher thermal conductivity compared to other metals. Consequently, precise control of heat input becomes essential during the welding process to avoid distortion or warping of the sheet.

- Q: How do you calculate the weight of a stainless steel sheet?

- To calculate the weight of a stainless steel sheet, you need to know its dimensions (length, width, and thickness) and the density of stainless steel. Multiply the area of the sheet (length x width) by the thickness and then multiply that by the density to obtain the weight.

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets is subject to variation based on the particular grade and composition of the stainless steel. In general, stainless steel possesses a substantial Young's modulus, typically falling within the range of 190 to 220 gigapascals (GPa). Consequently, stainless steel sheets exhibit considerable rigidity and resilience against deformation when subjected to external stress. Nevertheless, it is crucial to acknowledge that the precise Young's modulus can marginally differ due to factors such as temperature, manufacturing techniques, and the specific alloy employed in the stainless steel sheets.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- Fretting corrosion can be a common issue with stainless steel sheets, but there are several steps you can take to prevent it: 1. Proper Handling: When handling stainless steel sheets, it is crucial to avoid any scratching or rubbing of the surface that could lead to fretting corrosion. Use gloves and avoid contact with other metals or rough surfaces. 2. Cleaning: Regularly clean the stainless steel sheets using mild detergents or specialized stainless steel cleaners. This helps remove any contaminants that can initiate corrosion and also prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Lubrication: Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion. This is especially important in applications where there is repeated movement or vibration. 4. Avoiding Metal-on-Metal Contact: Whenever possible, try to isolate stainless steel sheets from direct contact with other metals. This can be done by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular Inspection: Periodically inspect the stainless steel sheets for any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Protective Coatings: Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. Consult with a professional to determine the most suitable coating for your specific application. 7. Proper Storage: When not in use, store stainless steel sheets in a clean, dry environment to minimize exposure to moisture or corrosive substances. Ensure that the storage area is well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, you can significantly reduce the risk of fretting corrosion on stainless steel sheets and prolong their lifespan.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- The difference between hot rolling and cold rolling of stainless steel is that cold rolling is rolled on the basis of hot rolling.

Send your message to us

Stainless Steel sheet and plate with Large Discount

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords