Stainless Steel Plate/Sheet for direct sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product details

|

304 St 304 Stainless Steel Sheet ainless Steel Sheet Metal

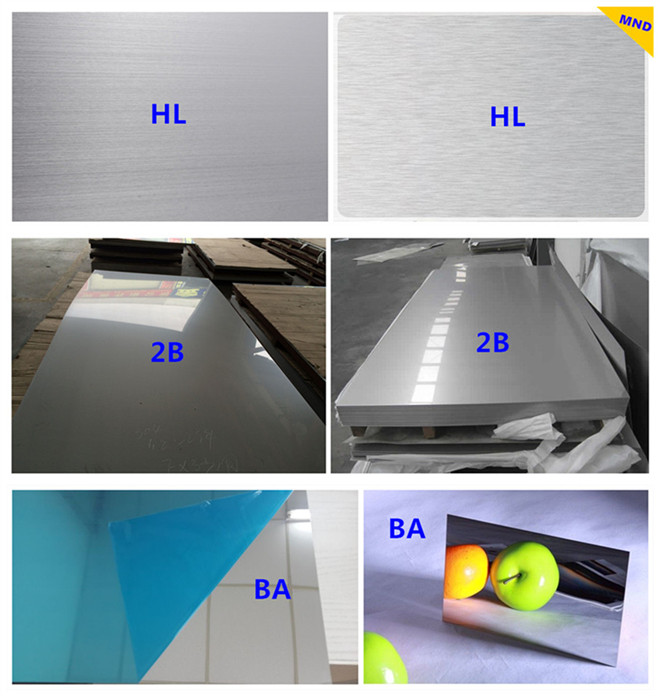

Surface:

- Q: What is the weight of a stainless steel sheet?

- The weight of a stainless steel sheet depends on its dimensions (length, width, and thickness).

- Q: Can stainless steel sheets be used for airport terminals?

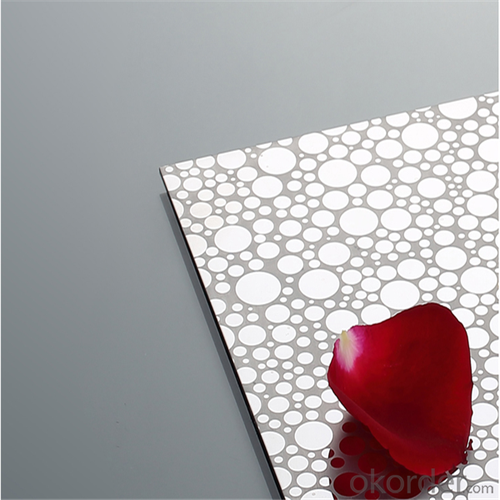

- Airport terminals can indeed make use of stainless steel sheets. Stainless steel, being an incredibly adaptable material, offers numerous advantages when employed in airport terminals. Initially, stainless steel boasts corrosion resistance, a crucial feature in a bustling environment like an airport where exposure to moisture and chemicals is commonplace. This characteristic guarantees that the structural integrity and appearance of the stainless steel sheets will endure over time. Furthermore, stainless steel sheets possess durability, enabling them to withstand heavy foot traffic and the wear and tear associated with airport operations. Consequently, they can be utilized for a variety of purposes within the terminal, including walls, ceilings, cladding, countertops, and furniture. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for areas with high foot traffic, such as airport terminals. Moreover, stainless steel brings forth an aesthetic appeal that can enhance the overall design of the airport terminal. Its sleek and modern appearance can create a sense of sophistication and elegance. Stainless steel sheets are available in different finishes, such as brushed, polished, or patterned, allowing for customization to meet the desired aesthetic requirements of the terminal. In conclusion, due to their corrosion resistance, durability, ease of maintenance, and aesthetic versatility, stainless steel sheets prove to be a practical and visually pleasing option for airport terminals.

- Q: What is the average lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. In general, stainless steel sheets are renowned for their durability and long-lasting nature. They are specifically engineered to withstand corrosion, rust, and other forms of degradation, making them suitable for a wide array of applications. Under ideal conditions and with adequate maintenance, stainless steel sheets can endure for several decades or even longer. However, in harsher environments that expose them to aggressive chemicals, extreme temperatures, or high levels of moisture, their lifespan may be shortened. To ensure the longevity of stainless steel sheets, it is crucial to engage in regular cleaning, proper storage, and routine inspections. By adhering to recommended maintenance practices, stainless steel sheets can deliver reliable performance and endure for an extended period.

- Q: Can stainless steel sheets be used for roofing applications?

- Yes, stainless steel sheets can be used for roofing applications. Stainless steel is a durable and corrosion-resistant material, making it suitable for use in outdoor environments. It is commonly used in architectural applications, including roofing, due to its strength, longevity, and aesthetic appeal. Stainless steel roofing sheets are available in different thicknesses and profiles, allowing for versatility in design. Additionally, stainless steel is fire-resistant and can withstand extreme weather conditions, making it a reliable choice for roofs.

- Q: What are the different types of stainless steel sheet thickness tolerances?

- The different types of stainless steel sheet thickness tolerances include standard, tight, and extra tight tolerances. Standard tolerances allow for slight variations in thickness, tight tolerances have lower permissible deviations, and extra tight tolerances have even smaller allowable variations in thickness.

- Q: How long do stainless steel sheets last?

- Stainless steel sheets are renowned for their durability and long-lasting nature. The lifespan of these sheets can vary depending on factors like the grade and quality of the stainless steel, environmental conditions, and maintenance practices. However, with proper care and normal circumstances, stainless steel sheets can endure for many decades or even a lifetime. The longevity of stainless steel is greatly influenced by its ability to resist corrosion. This is made possible by the presence of chromium, which forms a passive layer on the surface of the material, safeguarding it from rust and corrosion. This natural protective layer enables stainless steel sheets to withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. Moreover, the grade of stainless steel also plays a role in its lifespan. There are different grades available, such as 304, 316, and 430, each offering varying levels of corrosion resistance. Higher grades, particularly 316 stainless steel, exhibit greater resistance to corrosion and are commonly used in marine and highly corrosive environments, ensuring a longer lifespan. To maximize the lifespan of stainless steel sheets, proper maintenance is crucial. Regular cleaning with mild detergents and non-abrasive materials is necessary to eliminate dirt, grime, and contaminants that can degrade the protective layer of stainless steel. Additionally, it is important to avoid contact with harsh chemicals or abrasive materials that can scratch or damage the surface. While stainless steel sheets have an impressive lifespan, it is important to acknowledge that their durability is not limitless. Over time, factors like wear and tear, exposure to severe conditions, or improper maintenance can gradually diminish the protective layer of stainless steel and reduce its lifespan. Nonetheless, with appropriate care and maintenance, stainless steel sheets can be a cost-effective and enduring choice for various applications, including construction, automotive, and household products.

- Q: How do I bend or form stainless steel sheets?

- Bending or forming stainless steel sheets can be achieved through several methods. One common approach is using a sheet metal brake, which allows you to create precise bends by clamping the sheet between a flat surface and a hinged clamp. Alternatively, you can use a vise and hammer to gradually shape the stainless steel by tapping along the desired bend line. Another option is to employ a press brake, a more advanced machine commonly found in metal fabrication shops, to achieve accurate and complex bends. It is important to note that stainless steel is more rigid than other metals, so it may require more force and patience during the bending process. Additionally, using proper safety equipment, such as gloves and eye protection, is essential to ensure personal safety while working with stainless steel sheets.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps one can take. First, it is important to clean the sheets regularly using mild soap or detergent and warm water. Avoid abrasive cleaners or scrub brushes that could scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. In addition, it is crucial to avoid using harsh chemicals like bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural alternatives such as vinegar or lemon juice. Proper storage is also essential. Stainless steel sheets should be kept in a clean and dry environment to prevent exposure to moisture or humidity. Moisture can lead to corrosion or rust, resulting in discoloration. If the sheets are stored outdoors, make sure to adequately cover them to protect against rain or snow. Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available specifically designed for stainless steel protection. It is important to follow the manufacturer's instructions for application and reapplication if necessary. Furthermore, it is important to avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. To prevent this, ensure separation or isolation between stainless steel and reactive metals. Regular maintenance is crucial in preserving the appearance and integrity of stainless steel sheets. Regularly inspect the sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If stubborn stains are present, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, the appearance and integrity of stainless steel sheets can be maintained, ensuring they remain free from discoloration or staining for an extended period of time.

- Q: What are the common sizes and thicknesses available for stainless steel sheets?

- Common sizes for stainless steel sheets range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be produced. The thicknesses typically vary from 0.4mm to 6mm, with the most commonly used thicknesses being 0.8mm, 1mm, 1.2mm, and 1.5mm.

- Q: What are the different types of stainless steel sheet finishes for sanitary applications?

- For sanitary applications, various types of stainless steel sheet finishes are commonly used. These finishes are specifically designed to offer a smooth and clean surface that resists corrosion and bacteria growth. 1. One commonly used finish for stainless steel sheets in sanitary applications is the #4 Brushed Finish. It presents a brushed appearance that creates a consistent and uniform texture. This finish is easy to clean and maintain, making it perfect for environments where hygiene is of utmost importance. 2. Another option is the #8 Mirror Finish, which boasts a highly reflective surface resembling a mirror. It is visually appealing and easy to clean due to its smooth and shiny nature. However, it is worth noting that this finish may show scratches and fingerprints more readily than others. 3. The 2B Finish is generally applied to stainless steel sheets that will undergo further processing, such as fabrication or welding. It presents a dull and smooth appearance, providing a suitable base for additional treatments or coatings. 4. The Satin Finish, also known as a No. 4 finish, offers a low luster and smooth texture. It is frequently used in sanitary applications where a clean and aesthetically pleasing surface is desired. 5. A Bead Blast Finish is achieved by subjecting the stainless steel sheet to fine glass beads. This process results in a non-reflective surface that is uniform and easy to clean. It also provides resistance to corrosion, making it a popular choice for food processing plants and pharmaceutical facilities. 6. Lastly, the Electropolished Finish involves an electrochemical process that removes a thin layer from the stainless steel surface, leaving behind a smooth and shiny appearance. This finish offers a high level of cleanliness and resistance to corrosion, making it suitable for sanitary applications in the pharmaceutical and biotech industries. To ensure the best possible outcome, it is crucial to consider the specific requirements of the sanitary application when selecting the appropriate stainless steel sheet finish. Factors such as corrosion resistance, ease of cleaning, and aesthetic appearance should be taken into account.

Send your message to us

Stainless Steel Plate/Sheet for direct sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords