Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

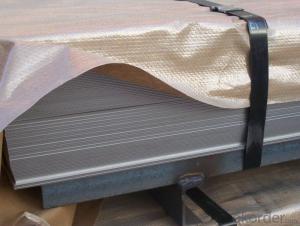

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion on stainless steel sheets can be prevented by using low carbon grades of stainless steel, such as the 304L or 316L alloys, which have reduced carbon content. Additionally, heat treatment processes like solution annealing can help eliminate carbide precipitation and reduce the susceptibility to intergranular corrosion. Finally, avoiding exposure to corrosive environments and implementing proper cleaning and maintenance practices can further minimize the risk of intergranular corrosion on stainless steel sheets.

- Q: Can stainless steel sheets be used for wire mesh?

- Yes, stainless steel sheets can be used to make wire mesh. The sheets can be cut into thin strips and then woven or welded together to create a sturdy and durable wire mesh. Stainless steel is a popular choice for wire mesh due to its corrosion resistance, strength, and versatility.

- Q: Can stainless steel sheets be used for kitchen sinks?

- Yes, stainless steel sheets can be used for kitchen sinks. Stainless steel is a popular material choice for kitchen sinks due to its durability, corrosion resistance, and easy maintenance. Stainless steel sheets are commonly used to fabricate kitchen sinks as they can be molded into various shapes and sizes. The smooth surface of stainless steel also makes it easier to clean and maintain hygiene in the kitchen. Additionally, stainless steel sheets are resistant to heat, stains, and scratches, making them a practical choice for a kitchen sink that is exposed to daily use and potential wear and tear.

- Q: Are stainless steel sheets suitable for water treatment plants?

- Yes, stainless steel sheets are highly suitable for water treatment plants. Stainless steel is known for its excellent corrosion resistance, which is crucial in water treatment facilities where the materials are constantly exposed to water and various chemicals. Stainless steel sheets are resistant to rust and corrosion caused by water, chlorine, chloramines, and other disinfectants commonly used in water treatment processes. Additionally, stainless steel is highly durable and can withstand high temperatures, making it ideal for use in water treatment plants where heat may be applied during certain treatment processes. Furthermore, stainless steel is hygienic and easy to clean, ensuring that the water remains free from any contaminants or impurities. Overall, stainless steel sheets are a reliable and long-lasting choice for water treatment plants due to their corrosion resistance, durability, and hygienic properties.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Yes, stainless steel sheets are highly suitable for water treatment facilities. Stainless steel is known for its corrosion resistance, which is crucial in an environment where water and chemicals are constantly present. It is resistant to rust and degradation, ensuring the longevity and durability of the sheets. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for facilities that require regular hygiene and sanitation. The material is also highly resistant to heat and extreme temperatures, ensuring its performance even in demanding conditions. Moreover, stainless steel is non-reactive, meaning it does not release harmful substances into the water during treatment processes, making it safe and reliable for water treatment applications.

- Q: Can stainless steel sheets be used for chemical mixing tanks?

- Yes, stainless steel sheets can be used for chemical mixing tanks. Stainless steel is highly resistant to corrosion and chemical damage, making it a suitable material for containing and mixing various chemicals. Additionally, its smooth surface prevents the buildup of bacteria and allows for easy cleaning and maintenance.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The strain hardening exponent of stainless steel sheets typically ranges from 0.2 to 0.4, depending on the specific grade and manufacturing process.

- Q: Can stainless steel sheets be used for elevator doors?

- Elevator doors can indeed utilize stainless steel sheets. The use of stainless steel for elevator doors is quite prevalent due to its impressive attributes: its robustness, resistance to corrosion, and visually appealing nature. Stainless steel is able to withstand the daily wear and tear associated with elevator usage, remaining unscathed by scratches, dents, and stains. Moreover, stainless steel grants a sleek and contemporary appearance, rendering it a suitable material for elevator doors in various settings like commercial edifices, residential complexes, and hotels. Furthermore, stainless steel sheets can be tailored to fulfill specific design requisites, enabling a wide array of finishes, textures, and patterns to be employed, elevating the overall aesthetic of the elevator doors.

- Q: Are stainless steel sheets resistant to chemicals?

- Generally, chemicals do not pose a problem for stainless steel sheets. Stainless steel is famous for its ability to resist corrosion, which is why it is widely used in industries like chemical processing, pharmaceuticals, and food processing. The presence of elements like chromium and nickel in stainless steel forms a protective layer on its surface, preventing most chemicals from penetrating. However, it's important to note that the resistance to chemicals may vary depending on the grade and composition of the stainless steel used. In highly aggressive environments or when dealing with specific chemicals, it's advisable to consult a materials engineer or refer to compatibility charts to ensure the best stainless steel grade is chosen.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Yes, stainless steel sheets are commonly used in aerospace applications due to their excellent strength, corrosion resistance, and high-temperature capabilities. These sheets are suitable for various components such as aircraft bodies, engine parts, and structural elements, ensuring reliable performance and durability in demanding aerospace environments.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords