Stainless steel plate/sheet 304,201,202,310,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

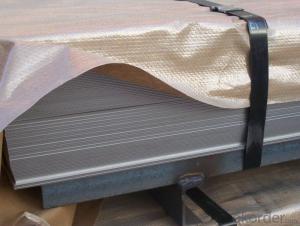

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: 304 why is stainless steel magnetic?

- 304 stainless steel after cold processing, the structure of the structure will also change to martensite, and the greater the deformation degree of cold work, the more martensite transformation, the greater the magnetism. Like a lot of stainless steel wire, made straight, no obvious induction, but it is bent into a rectangular or circular, and produce some magnetic for cold bending deformation is large, especially the angle of magnetic is more obvious.In order to eliminate the magnetism of the 304 stainless steel, the austenite structure can be recovered by high temperature treatment so as to eliminate magnetism.Special remind is, 304 magnetic stainless steel because it causes, and other materials such as stainless steel, carbon steel, magnetic 430 is not the same level, that is to say the magnetic stainless steel 304 is always weakly magnetic.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is a preferred material in cleanroom environments due to its inherent qualities such as corrosion resistance, durability, and ease of cleaning. It is non-porous, making it resistant to bacteria, mold, and other contaminants. Additionally, stainless steel is able to withstand frequent sanitization procedures without deteriorating, making it a reliable choice for maintaining a clean and sterile environment in pharmaceutical cleanrooms.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: What are the different types of stainless steel sheet finishes available?

- Available are various types of finishes for stainless steel sheets, each possessing its own distinct characteristics and applications. Some of the most commonly used finishes include: 1. No. 1 Finish, also referred to as hot rolled or annealed and pickled finish, represents the most basic type of stainless steel sheet finish. It exhibits a rough and dull appearance with a non-reflective surface. This finish is typically employed in industrial applications where aesthetics are not of primary importance. 2. No. 2B Finish is a smooth and semi-reflective finish achieved through cold rolling, annealing, and pickling. It boasts a slightly glossy appearance and is commonly utilized in applications requiring a moderate level of corrosion resistance. 3. No. 4 Finish is accomplished through the polishing of the stainless steel sheet using a fine abrasive material. This finish presents a brushed appearance with a low gloss finish. It finds frequent use in architectural and decorative applications, such as kitchen appliances, countertops, and elevator panels. 4. No. 8 Finish, also known as a mirror finish, is the most reflective type of stainless steel sheet finish available. It is achieved by progressively polishing the surface with finer grits until a mirror-like finish is attained. This finish is frequently employed in decorative applications, including architectural accents, signage, and ornamental pieces. 5. Satin Finish exhibits a smooth, satin-like appearance with a low to medium gloss level. It is achieved through a combination of brushing and polishing techniques. This finish is often utilized in applications that require a balance between aesthetics and functionality, such as kitchen equipment, sanitary appliances, and automotive trim. 6. Bead Blasted Finish is accomplished by subjecting the surface of the stainless steel sheet to high-pressure blasting with glass beads. This creates a uniform and matte appearance with a subtle texture. It is commonly used in architectural and interior design applications, such as wall panels, elevator doors, and furniture. 7. Embossed Finish is achieved by mechanically imprinting a pattern onto the surface of the stainless steel sheet. This creates a textured appearance that can range from subtle to dramatic, depending on the chosen pattern. It is often employed in decorative applications, such as wall cladding, signage, and decorative panels. These examples merely scratch the surface of the numerous stainless steel sheet finishes available. The choice of finish depends on the specific requirements of the application, including considerations of aesthetics, corrosion resistance, and functionality.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are highly suitable for chemical storage tanks. Stainless steel is corrosion-resistant, durable, and can withstand high temperatures and pressures. It provides excellent resistance against a wide range of chemicals, making it ideal for storing various types of chemicals safely and securely.

- Q: Can stainless steel sheets be used for roofing or cladding?

- Certainly! Roofing or cladding can definitely utilize stainless steel sheets. Stainless steel, being a durable and resistant material, is perfectly suitable for exterior purposes. It provides exceptional strength and can endure severe weather, thus making it an ideal option for roofing or cladding. On top of that, stainless steel presents a sleek and contemporary look that can enhance a building's aesthetic charm. Moreover, its long-lasting nature and minimal maintenance needs make it a cost-effective choice in the long term. All in all, stainless steel sheets are a dependable and adaptable option for roofing or cladding ventures.

- Q: Can stainless steel sheets be used for architectural wire mesh?

- Yes, stainless steel sheets can be used for architectural wire mesh. Stainless steel is a highly versatile material that is commonly used in architectural applications due to its durability, aesthetic appeal, and corrosion resistance. When formed into sheets, stainless steel can be easily manipulated and woven to create wire mesh panels that are suitable for various architectural purposes, such as building facades, interior partitions, sunscreens, and balustrades. The use of stainless steel sheets for architectural wire mesh allows for the creation of intricate and visually appealing designs while providing strength, stability, and longevity to the structure. Additionally, stainless steel wire mesh can be customized in terms of mesh size, wire diameter, and finish to meet the specific requirements of each architectural project.

- Q: What is the elongation percentage of stainless steel sheets?

- The elongation percentage of stainless steel sheets can vary depending on the grade and thickness of the sheets, but typically ranges from 40% to 60%.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Stainless steel sheets are a perfect choice for decorative purposes. They possess a sleek and contemporary appearance, which adds a touch of elegance and sophistication to any given space. The smooth and reflective surface of stainless steel creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Furthermore, stainless steel is incredibly durable and corrosion-resistant, making it an excellent long-term option for decorative use. The versatility of stainless steel sheets allows them to be utilized in various decorative forms, including wall panels, backsplashes, countertops, and even furniture. Regardless of whether they are used in residential or commercial settings, stainless steel sheets can be employed to create remarkable and attention-grabbing decorative elements that perfectly complement any interior design style.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it ideal for storage racks that may be exposed to moisture or other harsh conditions. Stainless steel sheets can be fabricated into various shapes and sizes to suit different storage needs, and they can support heavy loads without warping or bending. Additionally, stainless steel is easy to clean and maintain, ensuring a hygienic storage environment. Overall, stainless steel sheets are a reliable choice for storage racks in industries such as food and beverage, pharmaceuticals, and warehouses.

Send your message to us

Stainless steel plate/sheet 304,201,202,310,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords