Stainless steel sheet 304/304L,202,310S,316L,316Ti,410,420

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

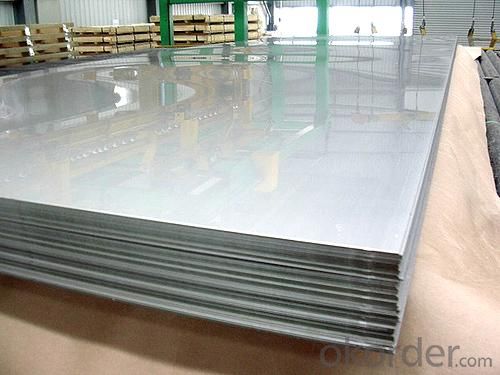

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: Can stainless steel sheets be used for hygienic applications?

- Stainless steel sheets are indeed suitable for hygienic applications. The reason lies in its remarkable hygiene properties attributed to the non-porous surface, which effectively resists bacteria, mold, and other microorganisms. Moreover, stainless steel is effortless to clean and maintain, making it perfect for sectors that prioritize cleanliness and hygiene, including the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Furthermore, stainless steel exhibits exceptional durability, corrosion resistance, and high-temperature tolerance, rendering it a superb choice for hygienic applications.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved. Etching and engraving are common methods used to create designs, patterns, and text on stainless steel surfaces. These techniques involve removing a thin layer of the metal to create the desired design. Etching can be done using chemicals or by using a laser, while engraving is typically done using a mechanical tool or laser. The etching or engraving process can create intricate and detailed designs on the stainless steel sheets, making them suitable for a wide range of applications such as signage, decorative panels, nameplates, and more.

- Q: Are stainless steel sheets good for pressure vessels?

- Yes, stainless steel sheets are indeed good for pressure vessels. Stainless steel is known for its excellent corrosion resistance, strength, and durability, making it an ideal material for containing fluids or gases under high pressure. It can withstand extreme temperatures and is resistant to chemicals, making it a reliable choice for pressure vessel applications in various industries such as oil and gas, chemical processing, and food processing.

- Q: What is the ductility of stainless steel sheets?

- Stainless steel sheets possess a remarkable quality known as ductility. This quality enables them to endure tensile stress without succumbing to fractures or breaks. The stainless steel material is renowned for its outstanding ductility, which grants it the ability to withstand stretching, bending, or hammering without compromising its structural integrity. This exceptional attribute endows stainless steel sheets with great versatility, rendering them suitable for an extensive array of applications such as construction, automotive manufacturing, and kitchen appliances. The high ductility of stainless steel empowers it to be effortlessly molded into intricate shapes or rolled into thin sheets, making it an ideal choice for delicate designs or structures with thin walls. Moreover, the ductility of stainless steel also facilitates easy welding, solidifying its status as a favored option for fabrication processes.

- Q: What are the different sizes available for stainless steel sheets?

- Stainless steel sheets are available in a wide range of sizes to cater to various applications and requirements. The most common sizes for stainless steel sheets are typically 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These sizes are widely used in construction, architecture, and industrial settings. However, stainless steel sheets are also available in smaller sizes, such as 2 feet by 4 feet (609mm x 1219mm) or even smaller, which are commonly used for DIY projects, hobbyists, and smaller-scale applications. On the other hand, larger sizes of stainless steel sheets are also available for specific purposes. These can include sheets measuring up to 5 feet by 10 feet (1524mm x 3048mm) or even larger, which are often used in specialized industries like shipbuilding, oil and gas, or manufacturing. It is important to note that the thickness of stainless steel sheets can vary independently of their size, as different applications may require different thicknesses. Common thicknesses range from 0.025 inches (0.64mm) to 0.1875 inches (4.76mm) or even thicker for specialized applications. Overall, the availability of stainless steel sheets in various sizes allows for flexibility and customization according to the specific needs of a project, whether it be a small DIY endeavor or a large-scale industrial application.

- Q: What are the applications of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties. They are commonly used in construction for roofing, cladding, and facades as they offer durability, corrosion resistance, and aesthetic appeal. In the automotive industry, stainless steel sheets are utilized for manufacturing various components, including exhaust systems, grilles, and body panels. They are also employed in the food processing and pharmaceutical industries for their hygienic properties. Additionally, stainless steel sheets find applications in kitchen appliances, chemical plants, marine equipment, and medical instruments, among others.

- Q: Are stainless steel sheets safe for contact with food?

- Yes, stainless steel sheets are safe for contact with food. Stainless steel is a non-reactive and non-toxic material, making it an excellent choice for food preparation and storage. It does not leach any harmful chemicals or flavors into the food and is resistant to corrosion, ensuring hygiene and safety.

- Q: How do you install stainless steel sheets?

- To install stainless steel sheets, start by measuring and marking the area where you want to install them. Then, use a circular saw or a metal shear to cut the sheets to the desired size. Next, clean the surface where the sheets will be installed and remove any debris or dust. Apply adhesive or a construction-grade adhesive tape to the back of the stainless steel sheet and carefully place it onto the prepared surface, ensuring it is aligned correctly. Use a roller or a block of wood to press the sheet firmly to the wall to ensure proper adhesion. Finally, secure the sheets in place with construction-grade adhesive or stainless steel screws, ensuring they are evenly spaced.

- Q: Can stainless steel sheets be used in food processing industry?

- Yes, stainless steel sheets are commonly used in the food processing industry due to their hygienic properties, corrosion resistance, and durability. They are suitable for various applications such as food storage, preparation surfaces, equipment, and production areas.

- Q: Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a safe and hygienic material for storing food as it is non-reactive, resistant to corrosion, and does not leach any harmful substances into the food. It is commonly used in commercial kitchens and food processing industries due to its durability and ease of cleaning.

Send your message to us

Stainless steel sheet 304/304L,202,310S,316L,316Ti,410,420

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords