Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

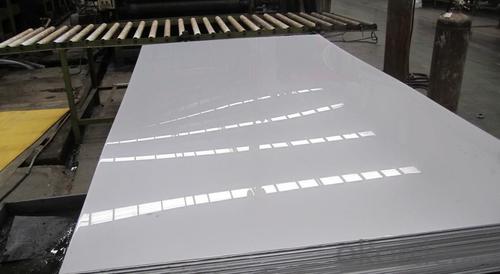

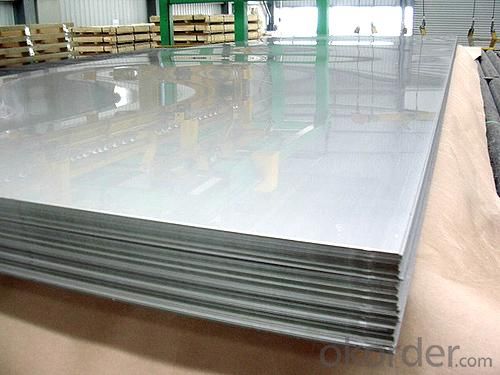

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are stainless steel sheets made of?

- Stainless steel sheets are made from a type of steel alloy that contains a minimum of 10.5% chromium. The addition of chromium creates a protective layer on the surface of the steel called a passive film, which makes stainless steel resistant to corrosion and staining. In addition to chromium, stainless steel sheets may also contain other elements such as nickel, molybdenum, and nitrogen, which enhance its mechanical properties and corrosion resistance. The specific composition of stainless steel sheets can vary depending on the desired properties and applications.

- Q: Can stainless steel sheets be used for storage containers?

- Yes, stainless steel sheets can be used for storage containers. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items safely and maintaining their integrity.

- Q: What is the price range of stainless steel sheets?

- The price range of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the thickness of the sheet, the size, and any additional finishes or coatings that may be applied. Generally, the price range for stainless steel sheets can start from around $20 per sheet for smaller sizes and standard grades, and can go up to several hundred dollars per sheet for larger sizes, higher grades, and specialized finishes. It is important to note that prices can also vary based on the supplier and market conditions, so it is advisable to compare prices from different sources to get the best deal.

- Q: Are stainless steel sheets safe for contact with food?

- Yes, stainless steel sheets are safe for contact with food. Stainless steel is a non-reactive and non-toxic material, making it an excellent choice for food preparation and storage. It does not leach any harmful chemicals or flavors into the food and is resistant to corrosion, ensuring hygiene and safety.

- Q: What is the minimum thickness of stainless steel sheets available?

- The minimum thickness of stainless steel sheets available can vary depending on the manufacturer and the specific grade of stainless steel being used. Generally, the thinnest stainless steel sheets available range from 0.4mm to 0.5mm. However, it is important to note that some manufacturers may offer thinner sheets, such as 0.3mm, but these may be more specialized or less commonly available. If you require a specific thickness for your project, it is recommended to consult with stainless steel suppliers or manufacturers to determine the options available to you.

- Q: Can stainless steel sheets be used for water filtration?

- Yes, stainless steel sheets can be used for water filtration. Stainless steel is known for its corrosion resistance, durability, and ability to withstand high temperatures, making it a suitable material for water filtration applications. Stainless steel sheets can be formed into various filter elements such as screens, mesh, or cartridges, which efficiently remove impurities and contaminants from water. The fine mesh size of stainless steel sheets allows for effective filtration while maintaining a high flow rate. Additionally, stainless steel is non-reactive and does not release harmful substances into the filtered water, ensuring its safety for consumption. Overall, stainless steel sheets are a reliable choice for water filtration due to their excellent mechanical properties and resistance to corrosion.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps you can take: 1. Regular Cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals such as bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural cleaners like vinegar or lemon juice. 3. Proper Storage: Store stainless steel sheets in a clean and dry environment to avoid exposure to moisture or humidity. Moisture can lead to corrosion or rust, which can cause discoloration. If the sheets are stored outdoors, cover them properly to protect them from rain or snow. 4. Use Protective Coatings: Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available in the market specifically designed for stainless steel protection. Follow the manufacturer's instructions for application and reapplication, if necessary. 5. Avoid Contact with Reactive Metals: Avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. Ensure separation or isolation between stainless steel and reactive metals. 6. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If you notice any stubborn stains, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets, ensuring they remain free from discoloration or staining for an extended period.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- Some of the different types of stainless steel sheet finishes for automotive applications include brushed, polished, satin, mirror, and textured finishes. These finishes vary in terms of appearance, texture, and level of reflectivity, providing options for various aesthetic preferences and functional requirements in the automotive industry.

- Q: What is the stainless steel grid board? What areas of stainless steel mesh panels are used in?

- Stainless steel grid plate, also called stainless steel steel grid plate, the two are the same product, just name different

- Q: Can stainless steel sheets be cut or welded?

- Yes, stainless steel sheets can be cut and welded.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords