Stainless Steel plate and sheet 409L with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

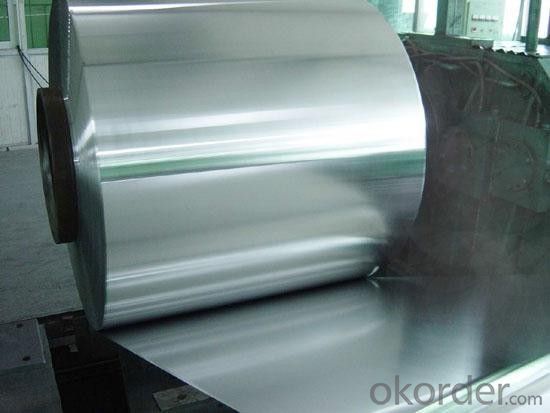

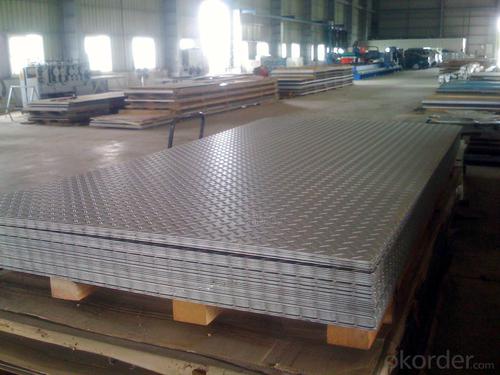

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do you remove adhesive from stainless steel sheets?

- One effective way to remove adhesive from stainless steel sheets is by applying a small amount of rubbing alcohol or acetone to a soft cloth and gently rubbing the adhesive residue. Another option is to use a mixture of warm water and mild soap, followed by scrubbing with a non-abrasive sponge or cloth. If the adhesive is particularly stubborn, using a commercial adhesive remover specifically designed for stainless steel can also be effective.

- Q: How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

- Q: Can stainless steel sheets be used for architectural cladding?

- Architectural cladding can indeed utilize stainless steel sheets. This material is incredibly versatile and offers numerous benefits for architectural applications. It boasts exceptional corrosion resistance, making it suitable for both interior and exterior cladding in diverse environments. Furthermore, stainless steel sheets are highly durable and require minimal maintenance, making them ideal for long-term use in architectural projects. Moreover, architects can achieve their desired aesthetic as stainless steel can be finished in various ways, enhancing its attractive appearance. Additionally, stainless steel's remarkable strength and fire resistance properties further enhance its suitability for architectural cladding. All in all, stainless steel sheets are a favored choice for architectural cladding due to their durability, resistance to corrosion, aesthetic appeal, and versatility.

- Q: What's the price of 06cr19ni10 and 304 stainless steel?

- 304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability).

- Q: Are stainless steel sheets good for pressure vessels?

- Yes, stainless steel sheets are commonly used for pressure vessels and are considered to be a good choice. Stainless steel offers excellent resistance to corrosion, high strength, and good mechanical properties, making it suitable for applications that require withstanding high pressures. Additionally, stainless steel has good heat resistance, which is important in pressure vessels where high temperatures may be encountered. It is also worth noting that stainless steel can be easily formed and welded, allowing for the fabrication of complex shapes and designs required for pressure vessel construction. Overall, stainless steel sheets are a preferred material for pressure vessels due to their durability, reliability, and ability to meet the demanding requirements of such applications.

- Q: How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can follow a few simple steps. First, ensure that the surface is clean and free from any dirt or debris. You can use a mild detergent or stainless steel cleaner to remove any stains or marks. Next, use a soft cloth or sponge to apply a stainless steel polish or a combination of vinegar and olive oil. Apply the polish in the direction of the grain, which is usually a linear pattern on the surface of stainless steel. Once the polish is applied, use another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to shine and appear polished. If necessary, repeat the process in areas that require additional polishing, and ensure that all excess polish is wiped away to avoid streaks or residue. It is important to note that different stainless steel finishes may require specific polishing techniques or products. Always refer to the manufacturer's instructions or guidelines for best results.

- Q: Can stainless steel sheets be used for storage tanks?

- Indeed, storage tanks can absolutely utilize stainless steel sheets. Stainless steel possesses a remarkable level of resistance to corrosion, rendering it an excellent material for the storage of a wide range of substances, such as chemicals, liquids, and gases. Its exceptional durability guarantees an extended lifespan for the storage tank, thereby minimizing the likelihood of leaks or contamination. Moreover, stainless steel tanks are effortless to clean and maintain, making them particularly suitable for industries like food and beverage, pharmaceuticals, and wastewater treatment. Furthermore, stainless steel is non-reactive, meaning it does not react with the stored substances, thus ensuring the integrity and quality of the materials being stored. All in all, stainless steel sheets serve as a dependable and versatile option for storage tank applications.

- Q: Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel prices higher: in terms of price, 304 is far higher than the price of 201. Because 304 quality is better than 201 stainless steel, and 304 for imported stainless steel plate, 201 for domestic stainless steel plate, so 304 of the price is naturally higher.

- Q: How do you prevent galling when using stainless steel sheets?

- To prevent galling when using stainless steel sheets, there are several measures you can take: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound on the contact surfaces to reduce friction. This helps to create a barrier between the stainless steel sheets and prevent them from sticking and galling. 2. Proper surface finish: Ensure that the stainless steel sheets have a smooth surface finish. Rough or uneven surfaces can increase the risk of galling. Consider using sheets with a polished or finely ground finish to minimize the chance of galling. 3. Control the contact pressure: Avoid excessive pressure when using stainless steel sheets. Excessive pressure can generate heat and increase friction, leading to galling. Adjust the pressure to a level that allows smooth movement without causing excessive friction. 4. Minimize sliding or rubbing: Reduce the amount of sliding or rubbing between stainless steel sheets. If possible, use rolling or lifting techniques instead of dragging or sliding the sheets across each other. This helps to minimize the risk of galling by reducing the contact area and friction. 5. Use compatible materials: When using stainless steel sheets in contact with other materials, ensure they are compatible. Some materials, such as aluminum or certain coatings, can promote galling when in contact with stainless steel. Choose materials that are less prone to galling or use protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat can increase the likelihood of galling in stainless steel sheets. Ensure that the temperature is controlled and does not reach levels that can cause the sheets to heat up significantly. This can be achieved through proper cooling methods or by using heat-resistant materials if necessary. By following these preventive measures, you can significantly reduce the risk of galling when using stainless steel sheets, ensuring smooth operation and prolonging the lifespan of the sheets.

- Q: Can stainless steel sheets be cut or welded?

- Yes, stainless steel sheets can be cut and welded.

Send your message to us

Stainless Steel plate and sheet 409L with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords