Stainless Steel plate and sheet 904L with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

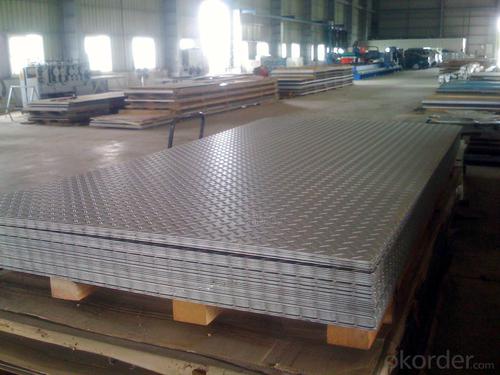

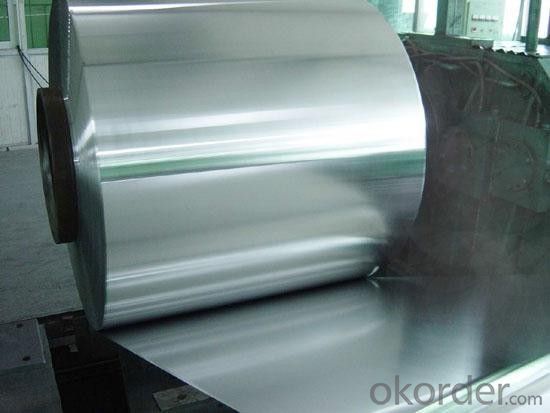

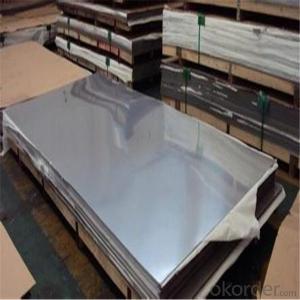

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for sink fabrication?

- Yes, stainless steel sheets can be used for sink fabrication. Stainless steel is a durable and corrosion-resistant material that is commonly used for sinks due to its hygienic properties and ease of cleaning.

- Q: What are the different types of stainless steel sheet coatings available?

- A variety of stainless steel sheet coatings are available, each with its own unique properties and benefits. Some commonly used coatings include: 1. Galvanized Coatings: These coatings protect stainless steel sheets from corrosion and rust by applying a layer of zinc. They are ideal for outdoor applications or environments with moisture or chemicals. 2. Powder Coatings: Offering excellent durability and corrosion resistance, powder coatings are a popular choice. They are applied as a dry powder and heated to form a protective layer. They come in various colors and finishes for customization. 3. Electroplating: This process involves depositing a thin layer of another metal, such as chrome, nickel, or zinc, onto the stainless steel sheet. It enhances appearance and improves resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings are created by depositing a thin film onto the stainless steel sheet using a vacuum process. They offer improved hardness, scratch resistance, and color options, making them suitable for architectural or decorative purposes. 5. Organic Coatings: Paints or lacquers can be applied as organic coatings to provide an extra layer of corrosion protection and aesthetic choices. They are commonly used when color matching or branding is important. Each stainless steel sheet coating has its own advantages and is suitable for specific applications. The choice of coating depends on factors such as intended use, desired appearance, and environmental conditions. It is important to carefully consider these factors and seek expert advice to select the most suitable coating for your needs.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are widely used in the food industry due to their numerous beneficial properties. One common use of stainless steel sheets in the food industry is for food processing equipment. These sheets are used to fabricate machines such as mixing tanks, conveyors, and food processing tables. Stainless steel sheets are preferred for this purpose because they are resistant to corrosion, easy to clean, and do not react with food substances, ensuring the food's safety and hygiene. Another common use of stainless steel sheets in the food industry is for food storage and transportation. Stainless steel sheets are often used to manufacture containers, tanks, and barrels that are used to store and transport food products. The corrosion resistance of stainless steel ensures that the food is protected from contamination and spoilage during storage and transportation. Stainless steel sheets are also used for kitchen equipment in the food industry. Countertops, sinks, and cabinets are frequently made from stainless steel sheets due to their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment such as ovens, grills, and refrigerators. These sheets are crucial in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In summary, stainless steel sheets are commonly used in the food industry for food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: What are stainless steel sheets used for?

- Stainless steel sheets are commonly used in various industries and applications, including construction, automotive, aerospace, food processing, and medical equipment manufacturing. They are primarily utilized for their exceptional resistance to corrosion, durability, and aesthetic appeal. Stainless steel sheets are employed in the production of architectural components, kitchen appliances, storage tanks, machinery parts, and decorative items, among others.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent galvanic corrosion on stainless steel sheets: 1. Opt for a suitable stainless steel alloy: Select a grade of stainless steel, such as 316 or 317, which is less susceptible to galvanic corrosion compared to 304 stainless steel. 2. Keep dissimilar metals separate: Avoid direct contact between stainless steel sheets and other metals, particularly those with a higher potential for galvanic corrosion. If contact is necessary, use insulating materials like gaskets or rubber pads to create a barrier between the metals. 3. Apply protective coatings: Use specially designed protective coatings or paints for stainless steel to create a barrier that shields against galvanic corrosion. These coatings act as sacrificial layers, safeguarding the stainless steel from direct contact with corrosive substances. 4. Utilize isolation materials: Install insulating materials, such as plastic washers, insulating tape, or non-conductive gaskets, between stainless steel sheets and other dissimilar metals. This prevents direct electrical contact and subsequent corrosion. 5. Maintain proper upkeep: Regularly clean and inspect stainless steel sheets to remove any contaminants or foreign substances that may contribute to corrosion. Avoid using abrasive cleaners or tools that could damage the protective layer of the stainless steel. 6. Employ electrochemical protection: Implement cathodic protection techniques, such as sacrificial anodes or impressed current systems, to introduce an external source of electrons that counteracts galvanic corrosion. These methods help shift the corrosion potential of the stainless steel sheets to a more passive range. By adhering to these preventive measures, the risk of galvanic corrosion on stainless steel sheets can be significantly reduced. This ensures their longevity and helps maintain their structural integrity.

- Q: Can stainless steel sheets be bent or formed without cracking?

- Yes, stainless steel sheets can be bent or formed without cracking. Stainless steel is known for its excellent formability and ductility, which allows it to be easily bent, shaped, or formed into various configurations. However, the extent to which stainless steel can be bent without cracking depends on several factors, including the grade and thickness of the stainless steel, the type of bending or forming process used, and the equipment and techniques employed. It is important to use proper bending techniques, such as using appropriate bending tools, applying gradual and consistent pressure, and avoiding excessive force or sharp bends, to prevent cracking. Additionally, preheating or annealing the stainless steel sheets can also improve their formability and reduce the risk of cracking during bending or forming operations.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The sizes and thicknesses of stainless steel sheets vary depending on their intended use and industry standards. However, there are standard sizes and thicknesses commonly found in the market. Stainless steel sheets are commonly available in sizes ranging from 4x8 feet (1219x2438mm) to 5x10 feet (1524x3048mm). These sizes are widely used in construction, automotive, and fabrication applications. In terms of thickness, stainless steel sheets come in a range of gauges, typically measured in inches or millimeters. The most frequently used thicknesses are 0.0276 inches (0.7mm), 0.0359 inches (0.91mm), 0.0478 inches (1.21mm), 0.0598 inches (1.52mm), 0.0747 inches (1.90mm), and 0.0897 inches (2.28mm). These thicknesses find frequent application in commercial and industrial settings. It is important to note that stainless steel sheets can be customized to meet specific requirements, encompassing non-standard sizes and thicknesses. In such instances, it is advisable to seek guidance from a supplier or manufacturer who can offer tailored solutions based on the project's unique needs.

- Q: Can stainless steel plate spray paint?

- Whether spraying or brushing any kind of paint, it should be divided into 3-5 construction, one can not be painted too thick, the last dry and then painted next time. The easiest thing for beginners to do is to apply too much paint at once, resulting in "hanging" flaws that are neither beautiful nor strong.

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Food packaging equipment can greatly benefit from the use of stainless steel sheets. The food industry favors stainless steel because of its many advantageous features. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. As a result, it is safe for direct contact with food products. Furthermore, stainless steel is resistant to corrosion, rust, and staining, ensuring the equipment's durability and longevity. Cleaning and sanitizing stainless steel is also a breeze, making it perfect for maintaining the high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process even further. Moreover, stainless steel possesses excellent strength and heat resistance properties, allowing it to withstand high temperatures without losing its shape or structural integrity. This is especially crucial in food packaging equipment that involves heat sealing or thermal processing. To sum up, stainless steel sheets are an excellent choice for food packaging equipment due to their non-reactive nature, resistance to corrosion, ease of cleaning, and high strength. These qualities ensure both the safety and quality of food products during packaging processes, making stainless steel a reliable and hygienic option.

Send your message to us

Stainless Steel plate and sheet 904L with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords