Stainless Steel plate and sheet 444 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

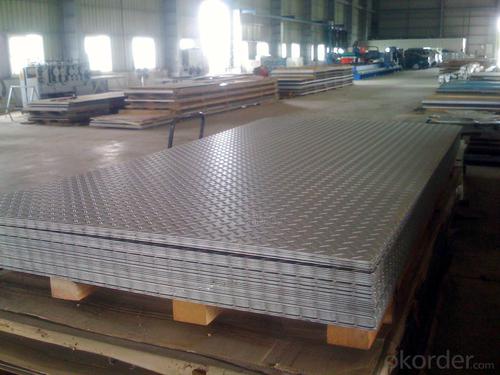

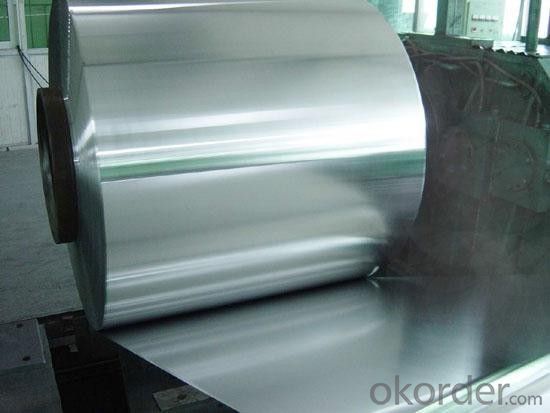

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- A continuous rolling mill is put in billions of dollars, but this is the rolling mill, and there are many gold furnaces. But the technical content of carbon steel with stainless steel is different, our country in more than 10 years ago the ability of continuous rolling of stainless steel is not high, equipment are imported, the stainless steel mill is dominated by 1219-1300, but also the development of national wide stainless steel 1500-2050, but the price is expensive at least thousands of dollars a ton, after all put the equipment to recover the cost, and the number of business orders is not much, it is difficult to find a spot on the market. Carbon steel countries have developed for many years, technology and equipment are mature, so the market has 1250 as production standards.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- There are several different types of etched finishes available for stainless steel sheets, each providing a unique and distinctive appearance. Some of the most common etched finishes include: 1. Brushed Finish: This is a popular etched finish that creates a uniform and linear texture on the surface of the stainless steel sheet. It is achieved by brushing the sheet with a fine abrasive material, resulting in a smooth and satin-like appearance. 2. Bead Blasted Finish: In this etched finish, small glass or ceramic beads are blasted onto the surface of the stainless steel sheet at high pressure. This process creates a non-directional and uniform texture, giving the sheet a matte and slightly rough appearance. 3. Mirror Finish: Also known as a No. 8 finish, this etched finish creates a highly reflective and mirror-like surface on the stainless steel sheet. It is achieved through a series of grinding, buffing, and polishing processes, resulting in a flawless and shiny appearance. 4. Satin Finish: This etched finish is similar to a brushed finish but has a finer and smoother texture. It is achieved by using a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish involves creating various patterns or designs on the surface of the stainless steel sheet. It can be achieved through techniques such as laser etching, chemical etching, or embossing, allowing for a wide range of creative and customizable options. These different etched finishes offer a variety of aesthetic choices for stainless steel sheets, allowing them to be used in various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the stainless steel sheet.

- Q: What are the standard sizes of stainless steel sheets?

- The specific industry and application dictate the varying standard sizes of stainless steel sheets. Nevertheless, there exist some widely accessible commonly used standard sizes. In the architectural and construction sector, stainless steel sheets usually come in sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to 5 feet by 10 feet (1524mm x 3048mm). These dimensions find common use in cladding, roofing, and interior design applications. In the manufacturing and industrial domains, stainless steel sheets are available in diverse sizes, including 4 feet by 8 feet, 4 feet by 10 feet (1220mm x 3050mm), and even larger sizes like 5 feet by 12 feet (1524mm x 3658mm). These larger dimensions frequently serve fabrication, industrial machinery, and equipment manufacturing purposes. It is important to acknowledge that custom sizes can also be produced according to specific project requirements. These custom sizes may encompass narrower or wider widths, longer or shorter lengths, or even different thicknesses to cater to a particular application's needs. Ultimately, industry standards, market demand, and manufacturer capabilities determine the standard sizes of stainless steel sheets. It is advisable to consult suppliers or manufacturers to verify the availability of the desired size before making a purchase.

- Q: How do you prevent fingerprints or smudges on stainless steel sheets?

- There are several effective measures you can take to prevent fingerprints or smudges on stainless steel sheets: 1. Regularly wipe down the stainless steel surface with a soft microfiber cloth. Microfiber is great at attracting and trapping dirt, dust, and oils without leaving streaks or smudges. 2. Use warm soapy water to gently clean the stainless steel surface. Mix a small amount of mild dish soap with warm water, then rinse thoroughly and dry with a clean towel. This method effectively removes grease, fingerprints, and smudges. 3. Consider investing in stainless steel cleaners that are specifically formulated to remove fingerprints and smudges. Follow the instructions on the product for best results. 4. Apply a stainless steel protective coating or sealant to create a thin, invisible barrier that repels fingerprints and smudges. Follow the manufacturer's instructions for application and reapply as needed. 5. Avoid using abrasive cleaners, scrub brushes, steel wool, or harsh chemicals that can damage the protective layer of stainless steel. Stick to non-abrasive cleaning methods and tools to maintain the integrity of the surface. 6. Handle stainless steel sheets with care by using clean hands or wearing gloves to prevent the transfer of oils or dirt. Avoid dragging objects across the surface, as this can cause scratches and make it more susceptible to smudging. By incorporating these measures into your cleaning routine and handling practices, you can effectively minimize fingerprints and smudges on your stainless steel sheets, keeping them clean and pristine.

- Q: Can stainless steel sheets be used for exterior cladding?

- Indeed, exterior cladding can utilize stainless steel sheets. The robustness and resistance to corrosion of stainless steel make it appropriate for various purposes, including cladding. Stainless steel sheets present exceptional endurance against weathering, UV rays, and extreme temperatures, rendering them perfect for external usage. They can endure severe environmental conditions, such as heavy rain, snow, and strong winds, without deteriorating or losing their aesthetic charm. Moreover, stainless steel sheets are available in an extensive array of finishes, allowing for customization and design adaptability. Whether for residential, commercial, or industrial edifices, stainless steel cladding offers a durable and visually pleasing solution.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can use a microfiber cloth or a soft cloth dampened with warm soapy water to gently wipe away the fingerprints. Avoid using abrasive cleansers or scrub brushes as they can damage the brushed finish. Dry the surface thoroughly with a clean cloth to prevent water spots.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a popular choice for food processing equipment due to its excellent corrosion resistance, durability, and hygienic properties. It is highly resistant to staining, rusting, and contamination, making it suitable for direct contact with food. Stainless steel sheets are commonly used for surfaces such as countertops, work tables, and food preparation areas in commercial kitchens and food processing facilities. Additionally, stainless steel is easy to clean and maintain, which is crucial in ensuring food safety and compliance with industry regulations.

- Q: What kind of screws do you choose for stainless steel plates?

- If it's a fixed plate, ordinary ones will doOf course, stainless steel screws are the best

- Q: How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, there are various steps that can be taken: 1. Opt for the appropriate stainless steel grade: Select a stainless steel grade that is resistant to stress corrosion cracking (SCC). Although grades like 304 and 316 generally have good SCC resistance, certain applications may necessitate higher alloyed grades like duplex or super duplex stainless steels. 2. Minimize exposure to corrosive environments: Limit the exposure of stainless steel sheets to environments known to cause stress corrosion cracking, such as chloride-rich or acidic surroundings. If avoiding exposure is not possible, consider applying protective coatings or barriers to shield the stainless steel from these corrosive elements. 3. Manage applied stress levels: Prevent subjecting the stainless steel sheets to excessive mechanical or thermal stresses. High tensile stresses can facilitate the initiation and propagation of stress corrosion cracking. Utilize appropriate design and fabrication techniques to ensure even stress distribution and minimize stress concentrations. 4. Maintain the surface condition: Ensure that the stainless steel sheets are devoid of surface contamination or defects that can serve as initiation sites for stress corrosion cracking. Regularly clean and inspect the sheets to eliminate any contaminants or corrosion products. 5. Employ inhibitors or cathodic protection: In certain cases where exposure to corrosive environments is unavoidable, the use of corrosion inhibitors or the implementation of cathodic protection techniques can help mitigate stress corrosion cracking. These methods work by reducing the corrosive activity on the stainless steel surface. 6. Handle and store properly: Exercise caution during transportation and storage to prevent excessive bending, vibration, or exposure to corrosive substances. Store stainless steel sheets in a clean and dry environment to avoid potential surface contamination. In conclusion, a combination of material selection, environmental control, stress management, surface maintenance, and proper handling can effectively prevent stress corrosion cracking on stainless steel sheets. It is advisable to consult with material experts or engineers to analyze specific application requirements and recommend the most appropriate preventive measures.

- Q: Can stainless steel sheets be used for heat shields?

- Yes, stainless steel sheets can be used for heat shields. Stainless steel is known for its high heat resistance and durability, making it an excellent choice for protecting against heat transfer. Stainless steel sheets can effectively shield against radiant heat, convective heat, and conductive heat, making them suitable for a variety of applications such as automotive heat shields, industrial equipment, and home appliances. Additionally, stainless steel sheets offer corrosion resistance and are easy to clean, making them a practical and long-lasting choice for heat shield applications.

Send your message to us

Stainless Steel plate and sheet 444 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords