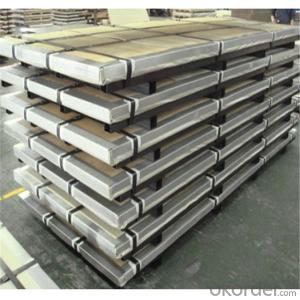

321 Stainless Steel Sheet with iso9001:2000 certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

321 stainless steel sheet with iso9001:2000 certified

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

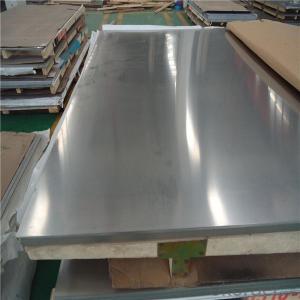

1. Steel grade: 321

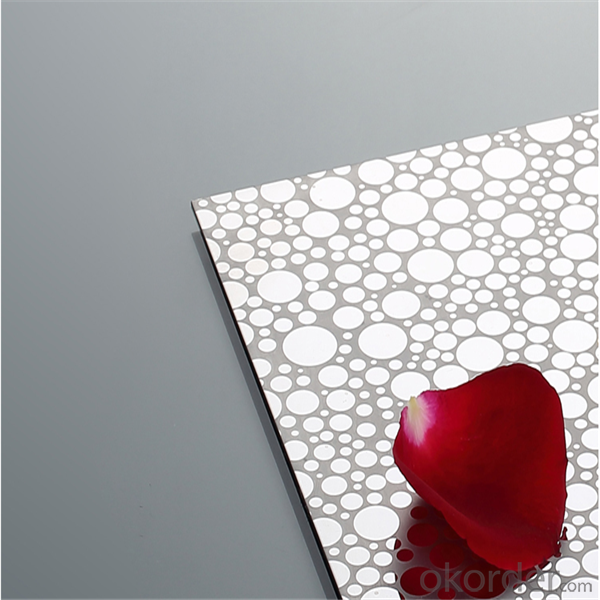

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

Product Name | cheap price 321 stainless steel sheet with iso9001:2000 certified, 321 stainless steel sheet, anti-slip steel plate, stainless steel sheet price 420 |

Steel type | Carbon steel, stainless steel, special alloy steel or as requested |

Process Method | Hot roll, cold roll, cold drawn, ect. |

Other processing method | Cutting, bending, punching, or as customer's request |

Size | Thickness from 0.15mm-300mm, width from 50mm-3500mm, length from 1m-12m or according to customer's special request |

Material grade | Carbon steel :Q195-Q420 Series,SS400-SS540 Series,S235JR-S355JR Series,ST Series,A36-A992 Series,Gr50 Series. Stainless steel: 201,202,304,316,410,420 |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Surface | mild steel plain finish, hot dip galvanized, color coated, ect. |

Size Tolerance | +/- 1%~3% |

Yield Strength | 250~600 MPa |

Tensile Strength | 350~800 MPa |

Packaging | Bundled with strong steel strips or with waterproof packing materials Special packings please discuss with us |

Certificate | API,ISO,SGS,BV,etc |

Capacity | 5000 tons/month, for non-standard customized products please discuss with us |

Delivery terms | FOB / CIF / CFR / DAP or discuss with us for other terms |

Delivery Time | 15-30 days after deposit received or L/C received in our bank |

Application Range | widely used in a variety of architectural and engineering structures,such as 1.) metal constructions such as buildings,bridges,ships; 2.) transmission tower, reaction tower; 3.) lifting transportation machinery; 4.) industrial furnace;boilers 5.) container frame, warehouse goods shelves, etc |

Advantages | 1. We can provide factory price with trading company services. |

2. We control production quality very strictly to keep none compensation. | |

3. We guarantee 24 hours response and 48 hours solution providing service. | |

4. We accept small order quantity before formal cooperation. |

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of embossed patterns to choose from. Some of the commonly seen options are as follows: 1. Diamond Pattern: This pattern showcases a series of diamond-shaped raised protrusions on the sheet's surface. It is a popular choice as it adds visual interest and texture to various applications. 2. Linen Pattern: The linen pattern features parallel lines that create a textured appearance resembling linen fabric. Architects and interior designers often utilize this pattern due to its unique aesthetic. 3. Squares Pattern: As the name suggests, this design consists of square-shaped raised protrusions on the stainless steel sheet. It provides a clean and modern look, suitable for a wide range of applications. 4. Leather Pattern: The leather pattern imitates the texture and appearance of leather, adding elegance and sophistication to stainless steel sheets. It is a favored choice for decorative purposes. 5. Moire Pattern: The moire pattern creates a wavy or rippled design, resulting in an optical illusion effect. It adds a dynamic visual element to stainless steel sheets, making them stand out. 6. Checkerplate Pattern: This pattern consists of raised squares or rectangles arranged in a checkered pattern. Its high slip resistance makes it ideal for applications where safety is crucial, such as stairs or ramps. These examples represent only a fraction of the embossed patterns available for stainless steel sheets. The choice of pattern depends on aesthetic preference, functionality, and specific application requirements. Whether for architectural, interior design, or industrial purposes, there is a wide range of embossed patterns to cater to various needs.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, there are several steps you can take: 1. Proper insulation selection: Choose insulation materials that are compatible with stainless steel and have a low water absorption rate. Avoid using materials that can cause galvanic corrosion when in contact with stainless steel. 2. Adequate insulation thickness: Ensure that the insulation thickness is sufficient to prevent moisture condensation on the stainless steel surface. Condensation can trap moisture and accelerate corrosion. Consult with an insulation specialist to determine the appropriate thickness for your specific application. 3. Vapor barriers: Install vapor barriers between the insulation and the stainless steel sheets. Vapor barriers act as a moisture barrier, preventing the ingress of water or moisture that can lead to corrosion. These barriers can be made of materials such as foil or plastic films. 4. Proper installation: Ensure that the insulation is properly installed, with no gaps or areas where moisture can accumulate. Pay close attention to joints, seams, and connections, making sure they are tightly sealed to prevent water penetration. 5. Regular inspection and maintenance: Regularly inspect the insulation system to identify any signs of damage, such as leaks or deterioration. Promptly repair any damaged insulation or vapor barriers to prevent moisture from reaching the stainless steel surface. 6. Ventilation: Provide adequate ventilation to prevent moisture buildup in enclosed spaces. Good airflow can help reduce the chances of condensation and subsequent corrosion. 7. Cathodic protection: Consider using cathodic protection methods, such as sacrificial anodes or impressed current systems, to protect stainless steel sheets from corrosion. These methods create an electrical current that counteracts the corrosion process, extending the lifespan of the stainless steel. Remember, it is essential to consult with corrosion specialists or insulation experts to ensure the best practices are implemented for your specific application and environment.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Indeed, swimming pool construction can utilize stainless steel sheets. Stainless steel, being a robust and corrosion-resistant material, proves to be an exceptional selection for pool construction. Its ability to endure chemicals and withstand the harsh swimming pool conditions, such as exposure to chlorine and saltwater, is highly commendable. Moreover, stainless steel sheets are effortless to clean and maintain, rendering them a popular choice for both residential and commercial swimming pools. Additionally, stainless steel adds a touch of sophistication and modernity, ultimately enhancing the pool's overall appearance. However, it is crucial to guarantee the usage of high-quality stainless steel sheets that meet industry standards to ensure prolonged performance and safety.

- Q: Can stainless steel sheets be used for railway station facades?

- Yes, stainless steel sheets can be used for railway station facades. Stainless steel is a durable and corrosion-resistant material that can withstand various weather conditions. Its aesthetic appeal and low maintenance requirements make it a suitable choice for enhancing the appearance and functionality of railway station facades.

- Q: Can stainless steel sheets be used for athletic equipment?

- Yes, stainless steel sheets can be used for athletic equipment. Stainless steel is known for its durability, corrosion resistance, and strength, making it an ideal material for various athletic equipment applications. It is commonly used in the construction of gym equipment such as weightlifting bars, dumbbells, and exercise benches. Stainless steel sheets are also used to manufacture basketball hoops, soccer goalposts, and other outdoor sports equipment due to their ability to withstand harsh weather conditions. Additionally, stainless steel sheets can be customized and fabricated into different shapes and sizes, making them versatile for various athletic equipment needs.

- Q: What is the elongation percentage of stainless steel sheets?

- The elongation percentage of stainless steel sheets can vary depending on the grade and thickness of the sheets, but typically ranges from 40% to 60%.

- Q: Are stainless steel sheets suitable for railway applications?

- Stainless steel sheets prove to be a fitting option for railway applications. They possess exceptional resistance to corrosion, rendering them perfect for utilization in settings constantly exposed to moisture, chemicals, and other harsh circumstances, such as railway tracks. Furthermore, these sheets exhibit notable strength and durability, essential qualities for enduring heavy loads and vibrations associated with railway operations. The material also showcases commendable heat resistance, enabling it to maintain its structural integrity even in high-temperature environments like railway brakes. Moreover, stainless steel sheets can be effortlessly molded and fabricated into diverse shapes and sizes, making them adaptable for various railway components such as cladding, paneling, and structural elements. All in all, stainless steel sheets offer a dependable and enduring solution for railway applications, ensuring the safety and performance of railway infrastructure.

- Q: What kind of screws do you choose for stainless steel plates?

- If it's a fixed plate, ordinary ones will doOf course, stainless steel screws are the best

- Q: Are stainless steel sheets good for heat exchanger tubes?

- Yes, stainless steel sheets are commonly used for heat exchanger tubes due to their excellent heat transfer properties and corrosion resistance. Stainless steel has a high thermal conductivity, allowing for efficient heat transfer between fluids. Additionally, it has exceptional resistance to corrosion, which is crucial for heat exchangers that often come into contact with liquids or gases that can be corrosive. The durability of stainless steel sheets also ensures longevity and reliability for heat exchanger tubes, making them a popular choice in various industries such as chemical processing, power generation, and HVAC systems.

- Q: Are stainless steel sheets good for chemical processing?

- Yes, stainless steel sheets are excellent for chemical processing. Stainless steel is known for its resistance to corrosion and chemical damage, making it a popular choice in various industries, including chemical processing. The high levels of chromium and nickel in stainless steel make it highly resistant to chemical reactions, even with harsh chemicals and acids. Additionally, stainless steel sheets are easy to clean, maintain, and sterilize, which is crucial in chemical processing environments where cleanliness and hygiene are paramount. The durability and strength of stainless steel sheets also ensure their longevity and ability to withstand high temperatures and pressure, making them suitable for a wide range of chemical processing applications. Overall, stainless steel sheets are a reliable and efficient choice for chemical processing due to their resistance to corrosion, ease of maintenance, and durability.

Send your message to us

321 Stainless Steel Sheet with iso9001:2000 certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords