Stainless Steel Metal Sheet with Personized Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Metal Sheet with Personized Thickness

Description of Stainless Steel Metal Sheet with Personized Thickness:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Metal Sheet with Personized Thickness:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel Metal Sheet with Personized Thickness:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel Metal Sheet with Personized Thickness:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Metal Sheet with Personized Thickness:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel Metal Sheet with Personized Thickness:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

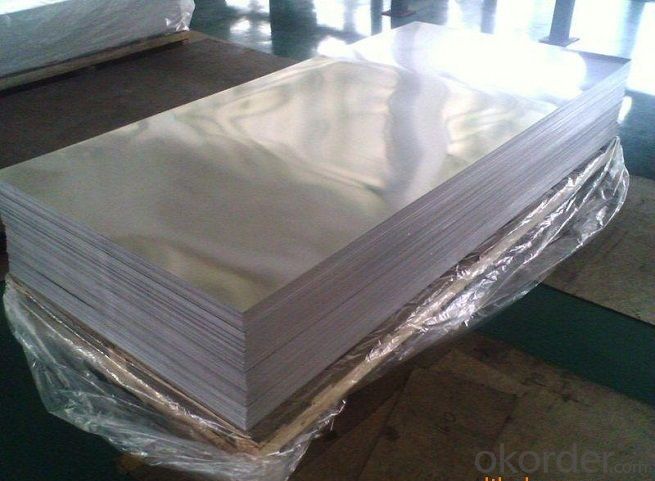

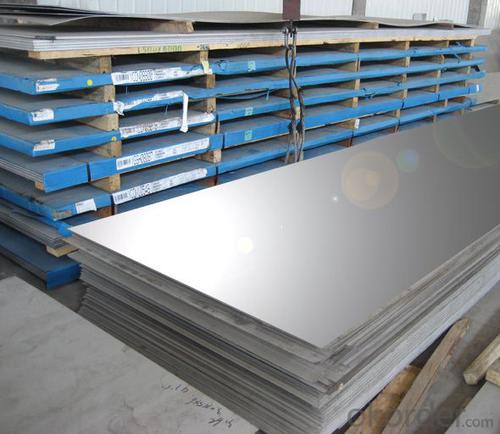

Images of Stainless Steel Metal Sheet with Personized Thickness:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: Are stainless steel sheets suitable for food processing?

- Indeed, stainless steel sheets prove to be an excellent choice for food processing purposes. The food and beverage industry extensively utilizes stainless steel owing to its exceptional properties and hygienic characteristics. Notably, it does not react with food, is highly resistant to corrosion, and does not introduce any taste or smell to the processed food. Moreover, stainless steel is effortless to clean and upkeep, rendering it an optimal selection for food processing machinery, worktops, and various other surfaces. Additionally, it withstands elevated temperatures and effectively resists bacterial proliferation, thereby establishing itself as a reliable and secure material for food processing activities.

- Q: Are stainless steel sheets non-magnetic?

- No, stainless steel sheets are not non-magnetic.

- Q: Can stainless steel sheets be used for conveyor belts?

- Certainly! Conveyor belts can utilize stainless steel sheets. Stainless steel, being highly durable and resistant to corrosion, is well-suited for diverse industrial uses, such as conveyor belts. These sheets possess the capability to endure high temperatures, heavy loads, and abrasive substances, making them perfect for conveying purposes. Moreover, the smooth surface of stainless steel facilitates the smooth movement of products and reduces friction, ensuring efficient and dependable conveyor operations.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- There are several cost considerations to bear in mind when buying stainless steel sheets. The cost is greatly influenced by the grade of stainless steel. Stainless steel comes in different grades, each with its own properties and levels of corrosion resistance. Higher grades like 316 or 304 are generally more expensive due to their superior corrosion resistance and durability. The size and thickness of the sheets also impact the cost. Thicker sheets are generally more expensive than thinner ones, and larger sheets are priced higher than smaller ones. It's important to accurately determine the required size and thickness to avoid unnecessary expenses. The surface finish is another factor that can affect the cost. Stainless steel sheets are available in various finishes, including brushed, mirror, or matte. Finishes that require additional processing or polishing usually add to the overall cost. Moreover, the quantity of sheets needed can have an impact on pricing. Bulk purchases often come with discounts or lower per-unit costs compared to buying small quantities. Transportation and delivery costs should also be taken into account. Stainless steel sheets are heavy and can be costly to transport, especially if shipping over long distances. These costs should be factored in to ensure that the overall purchase remains within budget. Finally, it is crucial to consider the reputation and reliability of the supplier. While lower-priced options may be tempting, it's important to ensure that the supplier offers high-quality stainless steel sheets that meet the required specifications. Purchasing from a reputable supplier may come at a slightly higher cost, but it guarantees the quality and reliability of the product. In conclusion, when purchasing stainless steel sheets, it's vital to consider the grade, size, thickness, surface finish, quantity, transportation costs, and the reputation of the supplier. By carefully considering these factors, one can make an informed decision that balances cost-effectiveness with the desired quality and specifications.

- Q: Are stainless steel sheets resistant to UV radiation?

- Yes, stainless steel sheets are generally resistant to UV radiation. The chromium content in stainless steel helps to form a protective oxide layer, which acts as a barrier against UV rays. This makes stainless steel a durable and reliable material for outdoor applications that are exposed to sunlight. However, prolonged exposure to intense sunlight may cause some slight discoloration or fading over time.

- Q: Can stainless steel sheets be used for elevator buttons?

- Yes, stainless steel sheets can be used for elevator buttons. Stainless steel is a popular material choice for elevator buttons due to its durability, corrosion resistance, and aesthetic appeal. It can withstand heavy usage, frequent contact, and is easy to clean and maintain. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of the elevator.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer numerous advantages in various applications. Firstly, their mirror-like surface adds elegance and style to any space, whether it be in interior design, architecture, or decorative pieces. The reflective nature of the mirror finish enhances the overall aesthetic appeal. Furthermore, these sheets are exceptionally durable and long-lasting. The high-quality stainless steel material used in their production ensures resistance to corrosion, rust, and staining, making them suitable for both indoor and outdoor use. This quality also makes them easy to clean and maintain, saving time and effort in upkeep. In addition, mirror-finish stainless steel sheets have the ability to reflect light, making them ideal for spaces that require enhanced lighting or where light distribution is important. The reflective surface helps brighten up the environment, making it perfect for areas such as kitchens, bathrooms, and commercial spaces. Moreover, these sheets are highly versatile and can be used in a wide range of applications. From kitchen countertops and backsplashes to wall claddings, elevator interiors, and even custom-made furniture, their versatility allows for creative and unique designs in various industries. Furthermore, mirror-finish stainless steel sheets have excellent heat resistance properties, making them suitable for applications involving high temperatures. This feature makes them a popular choice in commercial kitchens, industrial settings, and other environments where heat exposure is a concern. Lastly, mirror-finish stainless steel sheets are an environmentally friendly option. Stainless steel is highly recyclable, and using mirror-finish sheets promotes sustainability by reducing the need for new materials. This aligns with the growing emphasis on eco-friendly practices and the desire to reduce the carbon footprint. In conclusion, the advantages of mirror-finish stainless steel sheets include their elegant appearance, durability, light reflection capabilities, versatility, heat resistance, and eco-friendliness. These qualities make them a desirable choice for various applications, providing both aesthetic appeal and functional advantages.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets are known for their corrosion resistance, high strength and durability. They have a smooth and shiny appearance, making them visually appealing. Additionally, stainless steel sheets are heat and fire resistant, making them suitable for various applications in industries such as construction, automotive, and food processing.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Food packaging equipment can greatly benefit from the use of stainless steel sheets. The food industry favors stainless steel because of its many advantageous features. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. As a result, it is safe for direct contact with food products. Furthermore, stainless steel is resistant to corrosion, rust, and staining, ensuring the equipment's durability and longevity. Cleaning and sanitizing stainless steel is also a breeze, making it perfect for maintaining the high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process even further. Moreover, stainless steel possesses excellent strength and heat resistance properties, allowing it to withstand high temperatures without losing its shape or structural integrity. This is especially crucial in food packaging equipment that involves heat sealing or thermal processing. To sum up, stainless steel sheets are an excellent choice for food packaging equipment due to their non-reactive nature, resistance to corrosion, ease of cleaning, and high strength. These qualities ensure both the safety and quality of food products during packaging processes, making stainless steel a reliable and hygienic option.

- Q: What is the maximum length of a stainless steel sheet?

- The maximum length of a stainless steel sheet can vary depending on several factors, including the manufacturing capabilities, supplier limitations, and transportation constraints. In general, stainless steel sheets can be produced in lengths ranging from a few feet to several hundred feet. However, it is important to note that longer lengths may be more difficult to handle and transport, which could impact availability and cost. Additionally, custom orders or specialized applications may allow for even longer stainless steel sheets. Therefore, it is best to consult with manufacturers or suppliers to determine the specific maximum length options available for stainless steel sheets.

Send your message to us

Stainless Steel Metal Sheet with Personized Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords