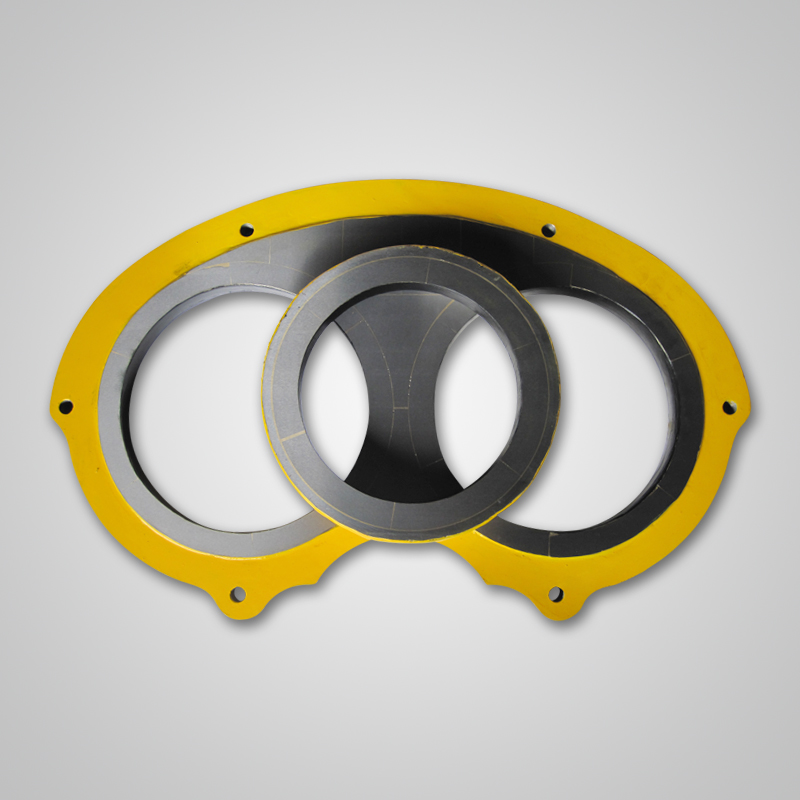

spectacle wear plate for SANY concrete pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

spare parts for SANY concrete pump

1.Specifications:

| Size | DN200, DN230,DN260 |

| Material | tungsten carbide, Q235B steel, Vautid-150 electrode imported from Germany |

| Lifetime | 30,000-80,000cbm |

| Carbide HRA | > 86 |

| Electrode HRC | > 63 |

| Type | hardfaced, tungsten carbide and 7 shape tungsten carbide |

| Application | mud pump, shotcrete,trailer and truck mounted concrete pump |

| Manufacturer with competitive price | |

Leading manufacturer for all kinds of brand concrete pump wear plate, technical date as below

| Technology | Technical Standard | Service Life | Hardness |

| Atmosphere sintering process | SY5064-85 | 5 times more than similar traditional product | HRC>70 |

| Tensile Strength | Fracture Toughness values | Yield Strength | |

| >1000Mpa | 10 Mpa1/2 | >1000Mpa | |

| Substrate/Matrix Material | Bending Strength | High Temprature Resistance | Surface Roughness |

| 45#,40Cr, 1Cr13 steel | 1100-1300 Mpa | 700-800 centigrade degree | Ra<0.1< td=""> |

| Bond Strength | Corrosion Resistance | Compactness | |

| >110Mpa | >95% | Gas Hole Ratio<0.01%< td=""> |

2.Packing:

1. Outside package: standard export wooden case

2. Inside package: bubble bag

3. Why choose us?

1. Manufacturers with 8 year's experiences.

2. High quality, best price, prompt delivery.

3. Standard quality control system

4. Small orders are accepted.

Experience: 1. over 8 years concrete pump wear part’s experiences.

2. 4 years gold supplier on alibaba.

3. 2 years OEM.

Quality: 1. ISO9001 certification.

2. Strictly quality control with every process.

3 . Material: electrode imported from Germany. Q235B steel body.

4. High performance.

5. Advanced manufacturing equipment and leading technical.

Type: Different types with different lifetime.

OEM, ODM is acceptable.

Service: Delivery: 7-10 days after receiving the money.

MOQ: 1 set.

Prompt attention must be paid to any requirement and inquiry.

Price: Different price with different types,

we are faithfully that our price can help you beat your competitor with the same type product.

We are leading manufacturer for concrete pump wear plate, S valve and other wear parts in the hopper for more than 8 years, with high quality and competitive price, all kinds of brand you can find from us, such as PM, Schwing, Sany, Zoomlion, Cifa, Sermac, IHI, Niigata, Mitsubishi, Kyokuto, KCP, Jacon, Elba...etc.

OEM service is available, products can be produced as buyer's drawing or samples.

At the same time, we also sell following parts with good quality and competitve price:

1. Concrete pump clamp in casted and forged

2. Concrete pump rubber hose

3. Delivery pipe and elbow

4. Piston

5. Sponge ball

6. Delivery cylinder

7. Plunger cylinder

Any questions, I am Hilary here. feel free to contact me.

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- Such as a large pressure of about 10m or about 0.1MPa} because the most unfavorable point fire hydrant requires more than 0.07MPa (7m) and 0.5MPa (50m) is not greater than the pressure, so unless the pump is located in the 50m Valley is still lower than the garage, or add to the valve (or the use of fire hydrant decompression) otherwise, it is 120m lift pump

- Q: Why should the pump be closed when the centrifugal pump is started?

- Centrifugal pump has an important characteristic: when the pressure (head) is very low, the flow will be great, which can be seen from the characteristics of the pump curve. While the pump power is directly proportional to the flow rate, pump start, no pressure in the pipeline, caused by the pump flow, high power pump, and the pump motor, the rotating part from rest to high-speed operation, need a lot of acceleration, it will cause a great starting current

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- Submersible pump even if it really leakage, it will not cause the fish electric shock. The so-called leakage is the submersible pump wire or shell broken, live parts and water contact, the most extreme test is a fire line directly into the fish tank

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- The entrance can be a negative pressure. You can often see someone pumping water from the pool. How can you pump water if it is not negative pressure?

- Q: The main factors affecting the performance of centrifugal pumps

- Revolutions required to have. It has the following meanings: 1, similar to the geometry of centrifugal pump, everywhere efficiency at the top of the similar condition; centrifugal pump 2, than the number of different, its geometry must be different than the number; the same pump, its shape is similar, but does not rule out the shape similar situation. The following factors are related to specific speed. The specific speed of centrifugal pump has nothing to do with the nature of the conveying fluid, but has a close relationship with the shape of the impeller and the performance curve of the pump. The pump with high specific speed corresponds to the highest efficiency when the flow rate is large and the head is small

- Q: What is pump suction work?

- Pump is mainly used to transport liquid, including water, oil, acid and alkali liquid, emulsion, suspension emulsion and liquid metal, etc., also can transport liquid, gas mixture and liquid containing suspended solids.

- Q: What is the displacement of the pump? Flow? What is the volume efficiency and mechanical efficiency of the pump?

- Displacement of a pump: the volume of the discharged liquid calculated by the change in the size of the sealing geometry for each revolution of the hydraulic pump

- Q: Household automatic booster pump, how much pressure to work automatically, the water pressure and how many kilograms?

- With the pressure does not matter, because the pressure is small, it is necessary to boost the pump, the water pressure with the pipe flow and the size of the booster pump related

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Here the roots pump and dry pump must be used, because the roots pump is not used alone, and must be a stage vacuum pump (pre vacuum pump can be dry pump, water ring vacuum pump and rotary vane vacuum pump can be, you here with dry pump series)

- Q: How accurate is the metering pump?

- In addition, when the oil supply is too large or the pipeline pressure rises unexpectedly, the volume of the liquid in the hydraulic chamber can be changed, thereby affecting the stability of the flow and reducing the metering accuracy of the pump. In order to solve the problem of how to stabilize the measurement accuracy of metering pump metering pump flow, how stable, the three valve device. The so-called actual refers to the combination of three functions including compensation, discharge and safety protection device or device supporting the hydraulic chamber, according to its action principle is different, is divided into automatic compensation and forced compensation two three valve device.

Send your message to us

spectacle wear plate for SANY concrete pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords