SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-ASeries

Based on SK series, is designed specially for the use of plastics industry. Therefore, many problems have been solved, for instance: incapability to work continuously, in case of sufficient wafter to be draw-out, dirts is resulted from sewage, impossibility to restart work after long pause. It is widely used in Tubing and Molding machinery.Items:SK-0.15A、SK-0.3A、SK-0.5A、SK-0.8A、SK-1.2A、SK-2A、SK-3A,Motor power:0.55~5.5KW,extract capacity :0.15~3(m3/min),Limit vacuum:-0.095MPa。

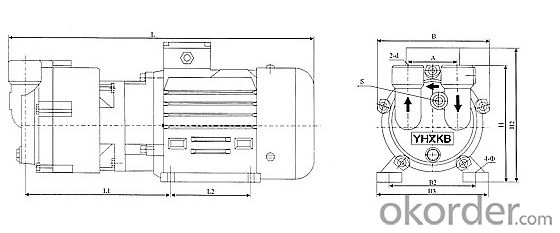

■List of size performance

■List of installation

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What are the advantages and disadvantages of the pump control system and valve control system in the hydraulic system? How to choose in the project?

- Large pump control valve controlled energy consumption at least 30% reason is that there are serious throttling loss of a throttle valve control system of severe fever but simple structure and low cost which is why now valve control system still occupy the main market reasons.Pump control system with complicated structure especially when serious nonlinear control unsymmetrical cylinder control effect is not ideal, but the biggest advantage is energy-saving and low fever America professor Monika points out that using the pump control system of hydraulic excavator energy efficiency compared with the valve control system can be improved by over 46% but costs are high. But in control, the three pump invented by Professor Quan LONG of China is a good solution. LZ can find the invention patent or find his paper on sage. It seems that there are three or four SCI about this pump

- Q: What is double hydraulic pump?

- Two hydraulic pumps installed on one shaft can be connected to increase output flow, and can also be connected to increase output pressure. See how the demand is. The system can change the mode of application at any time.

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- 1. submersible pumpsA very wide range of water treatment tools. Unlike ordinary water pumps, it works underwater, while the pump works mostly on the ground.The working principle of submersible pumpBefore the pump is opened, the suction pipe and pump must be filled with liquid. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet, the outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuously from the outflow discharge tube.Basic parameters of submersible pumpIncluding flow, lift, pump speed, matching power, rated current, efficiency, diameter and so onSubmersible pump main application and scope of applicationIncluding construction, construction, drainage, agricultural irrigation and drainage, industrial water recycling, urban and rural residents cited water supply, and even rescue, disaster relief and so on

- Q: What's the meaning of the pump head in the water pump, please advise, thank you

- The pump head of the centrifugal pump refers to the shell that contains the impeller and impeller, and also includes the shaft part that drives the impeller. It can be used as the part of the motor and shaft coupling and the base.

- Q: Operating procedures for measuring pumps

- Pressurization(1) for the discharge pressure below 2.0MPa, then the pump stroke length should gradually increase, each increase of 20%, to maintain 15 minutes.(2) for the discharge pressure greater than 2.0MPa, you need a special pressure, to ensure that the pump discharge pressure gradually increased, each time for the final row pressure of 20%.(3) when the pressure is not increased, the stroke of the pump is gradually increased by 20% strokes per time.Note (1) when pressure is applied, the pressure gauge should be observed at the side of the loading side (slow motion)(2) check ammeter, forbid overload

- Q: Difference between pump and compressor

- Working principle:The impeller is installed in the pump casing and is fastened on the pump shaft 3, and the pump shaft is directly driven by the motor. There is a liquid suction in the center of the pump shell, and 4 is connected with the suction pipe 5. The liquid through the bottom valve 6 and the suction tube into the pump.The liquid discharge port 8 on the pump housing is connected with the discharge pipe 9. Before the pump starts, the pump shell is filled with the liquid to be transported; after starting, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate. Under the influence of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, and leaves the outer edge of the impeller at high speed to enter the volute pump shell.

- Q: Household automatic booster pump, how much pressure to work automatically, the water pressure and how many kilograms?

- With the pressure does not matter, because the pressure is small, it is necessary to boost the pump, the water pressure with the pipe flow and the size of the booster pump related

- Q: Common failure treatment of piston pump

- Table 15 common troubles and treatment of hydraulic pumpsFault phenomenon, x09 cause analysis, x09 elimination method(1) the pump does not carry oil; the x091. pump does not turn x09 (1); the motor shaft does not rotate1) missed connection power supply2) electrical wiring and component failure, x09 check electrical and troubleshootx09x09 (2) motor heating trip

- Q: How many concrete pump tube diameter

- The pump tubing diameter is 125MM general concrete or mortar pump tube diameter is 80MM fine stone

- Q: Why can't the centrifugal pump pump the vacuum?

- Condition:The pump shell must be filled with liquid under certain installation height and running without leakage.What is the phenomenon of centrifugal pump? What harm does it have? How to eliminate?)

Send your message to us

SK-3A water ring vacuum pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords